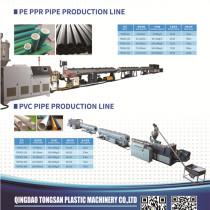

16-63mm SJMS55/125 double cavity PVC/CPVC Pipe Extrusion Line/Pipe Making Line/Pipe Extrusion Line/Production Line Made in China

group namePP PE PPR PVC Pipe Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJMS51/105

payment methodT/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeWed, 28 Oct 2020 13:23:42 GMT

Paramtents

Pipe diameter 16-63mm

Main extruder SJMS55/125

Extruder motor 250kw

Capacity 500-600kg/h

Production speed 5-20m/min

Motor brand SIEMENS

Inventer ABB

Temperture control OMRON

Packging & Delivery

Min Order1 piece

Briefing

Detailed

we have different models of PVC pipe making machine for making different PVC pipe diameter, below is our PVC pipe plant cost for your reference:

| Model | Diameter | Approximately price | Production capacity | Main extruder power |

| 55/125 | 16-63mm | 33000-38000 USD | 80-120kg/h | 22kw |

| 65/132 | 50-160mm | 40000-46000 USD | 150-240kg/h | 37kw |

| 80/156 | 160-315mm | 65000-72000 USD | 300-350kg/h | 75kw |

| 92/188 | 315-500mm | 190000-200000 USD | 400-500kg/h | 110kw |

2, Product Description

The production line adopts unique mold and sizing sleeve design, which can produce PVC solid pipe continuously and stably. PVC pipe has the features of strong corrosion resistance, easy adhesion, low price and hard texture. However, due to PVC-U monomer and additive bleed, it is only suitable for supplying water that the temperature not exceeding 45 ºC. PVC pipe is widely used in water drainage, sewage water, chemicals, heating fluids and coolants, food, ultra-pure liquids, mud, gas, compressed air and vacuun m systems.

3, Equipment List

| No. | Equipment list for PVC pipe manufacturing plant | Quantity |

| 1 | Mixing machine | 1 set |

| 2 | Auto feeder | 2 sets |

| 3 | Conical double screw extruder | 1 set |

| 4 | Die head and sizing mold | customized |

| 5 | 1st cooling tank | 1 set |

| 6 | 2nd cooling tank | 1 set |

| 7 | haul off device | 1 set |

| 8 | auto cutting machine | 1 set |

| 9 | Laser printer or ink jet printer | 1 set |

| 10 | PVC pipe stacker | 1 set |

| 11 | PVC pipe joint belling machine | 1 set |

| 12 | Crushing machine | 1 set |

| 13 | PVC powder milling machine | 1 set |

| 14 | Air compressor | 1 set |

| 15 | water chiller | 1 set |

4, Detailed Images

16-50mm double cavity PVC pipe extrusion line

Extruder for PVC pipe machine

Double cavity die head for 16-50mm

water tank for PVC pipe machine

haul off for PVC pipe machine

Auto cutter for PVC pipe machine

Product stacker

FAQ

1, DO YOU PROVIDE OEM SERVICE?

we accept OEM order to design the machine according to customer's special requirements.

2, HOW CAN I GET THE TECHNICAL PARAMETERS?

Please contact us for sending you detailed quotation with technical parameters

3, WHAT IS THE WARRANTY TERMS?

3.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER'S WAREHOUSE

3.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

3.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

4, WHAT IS THE DELIVERY CONDITIONS?

4.1 DELIVERY CONDITION: FOB QINGDAO PORT.

4.2 DELIVERY TERM: WITHIN 45 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

4.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER SHOULD ARRANGE FOR SUPERVISION OF LOADING.

5, WHAT IS THE PAYMENT TERMS?

5.1 INSTALLMENT I: 30% OF TOTAL PAYMENT TO BE PAID AT ADVANCE

5.2 INSTALLMENT II: THE BALANCE 70% OF TOTAL PAYMENT TO BE PAID BY TT OR LC AT SIGHT

6, HOW TO DO THE INSPECTION WORK BEFORE SHIPMENT?

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER'S FACTORY. THE BUYER SHOULD COME TO SELLER'S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER'S FACTORY TO DO THE INSPECTION WORK.

7, HOW TO DO THE INSTALLATION AND EQUIPMENT COMMISSIONING?

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER'S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE, AND THE BUYER SHOULD UNDERTAKE THE WHOLE FOOD/PLACE AND ROUND TICKETS (AIRPLANE, FOOD, HOTEL, AND SO ON), AND PAY SALARY TO ENGINEER FOR 80 USD/DAY/ENGINEER.

PS: Above Items are discussable according to customer's special requirements.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow