professional hdpe corrugated pipe extruder machine manufacturer

- US $34000.00

1 - 3 set

- US $32000.00

4 - 6 set

- US $30000.00

7 - 10 set

- US $29000.00

11 - 15 set

- US $28000.00

16 - 20 set

group nameSingle Wall Corrugated Pipe Machine

-

Min Order1 set

brand nametongsan

modelSJ65/30

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeTue, 08 Dec 2020 14:10:30 GMT

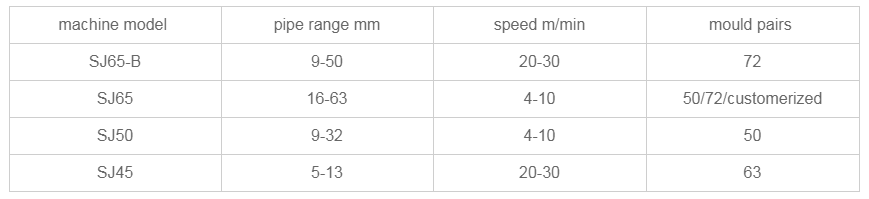

Paramtents

speed 20-30m/min

mould pairs 72

mould cavity single/double cavity

forming cooling water

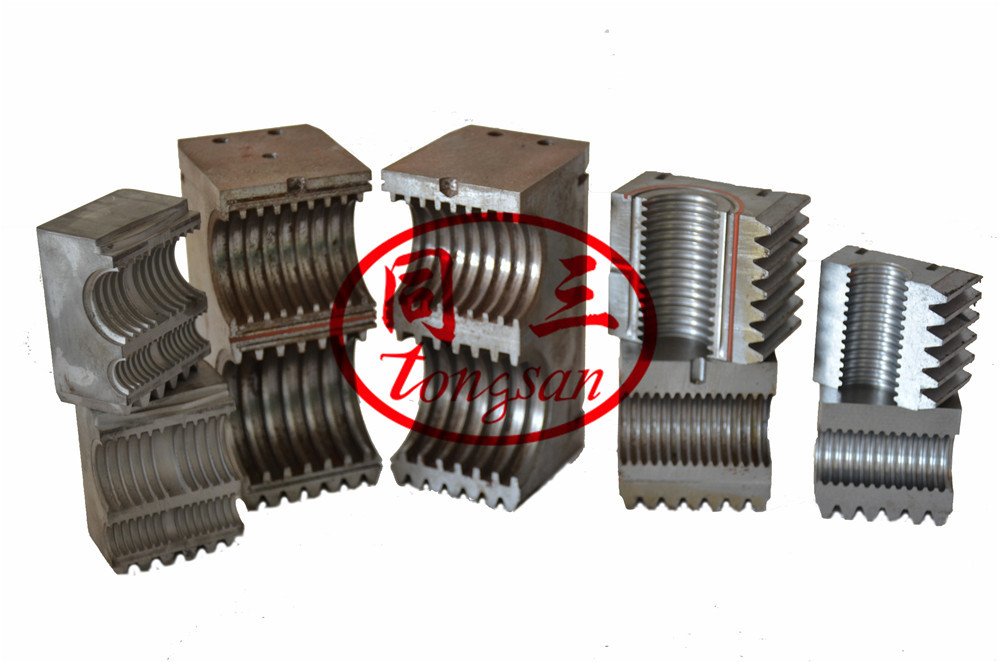

mould material 40Cr

mould block making our own CNC machine

machine in stock more than 30 sets

running machine run machine for any visitors

Packging & Delivery

Size100cm x 30cm x 30cm

Weight2000.00kg / set

Min Order1 set

Briefing

30 lines in stock

make mould by German CNC machine

10 engineers available for installation

Detailed

1, material for the single wall corrugated pipe and corrugated tube:

This production line can be used to produce corrugated pipes of PE,PP,PVC,EVA continuously,as well as PA corrugated pipes

2, application for the single wall corrugated pipe and corrugated tube:

Plastic single-wall corrugated pipes have feathers of high temperature resistance,resistant to corrosion and abrasion,high intensity,good flexibility,etc.They are widely used in fields of auto wire,electric thread-passing pipes,circuit of machine tool,protective pipes of lamps and lanterns wire,tubes of air conditioner and washing machine,etc.

3, advatanges of the single-wall corrugated pipe machine (the machine for corrugated tube):

SJDBGZ seies plastic single-wall corrugated pipe production line developed by our company adopts gears to run modules and templates so as to realize water circulating cooling and air cooling of the products,which ensures high-speed molding,even corrugation,smooth inner and outer pipe wall.These corrugated pipes are especially used as wires of the up-market cars.

This production line with good performance and reasonble price,it will be the best choice for your producing single-wall corrugated pipe.

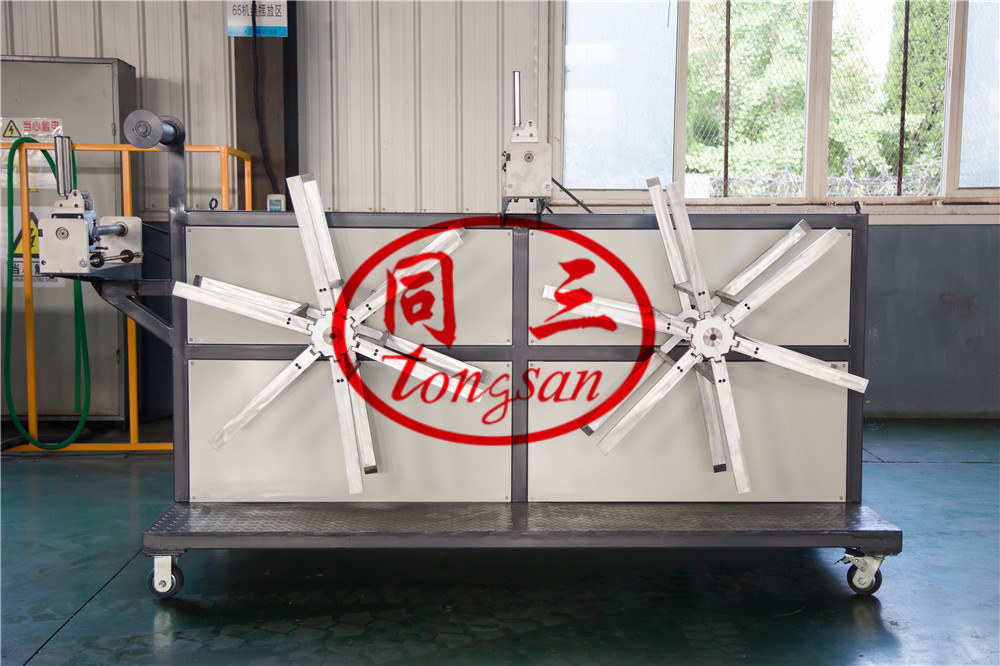

1) winding station: double station

2) winding method: automatic windinhg

3) meter counting: automatic counting

4) winding meters: customized

|

machine list

|

quantity

|

|

SJ65/30 single screw extruder with auto feeder and drying hopper

|

1 set

|

|

Die head

|

1 set

|

|

Mold: 72 pais of mold blocks

|

according to your request

|

Steel wire unwiding and inserting device | 1 set |

Forming machine: with water cooling | 1 set |

Coiling machine, double station | 1 set |

Electricity control system | 1 set |

Spare parts | 1 set |

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram