Wastage Wood Plastic Composite WPC Decking Extrusion Line Machine

group namePP PE WPC Profile Machine

-

Min Order1 piece

brand nametongsan

modelSJ65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeWed, 23 Sep 2020 14:30:30 GMT

Paramtents

Plastic Material PE/PP Recycled Plastic Material

Wood Material Wood Sawdust/Rice Husk/Straw/Cotton Straw

Processing Mixing, Granulating, Extrusion

Packging & Delivery

Min Order1 piece

Briefing

ECO friendly

finish product: decking, pergola, fence, chair,wall...

Detailed

|

Plastic material

|

recyccled PP/PE plastic

|

|

Wood material

|

wood powder from rice husk/straw,wheat husk/straw,wood sawdust,wastage wood

|

|

Percentage of plastic

|

25-30%

|

Percentage of wood powder | 50-70% |

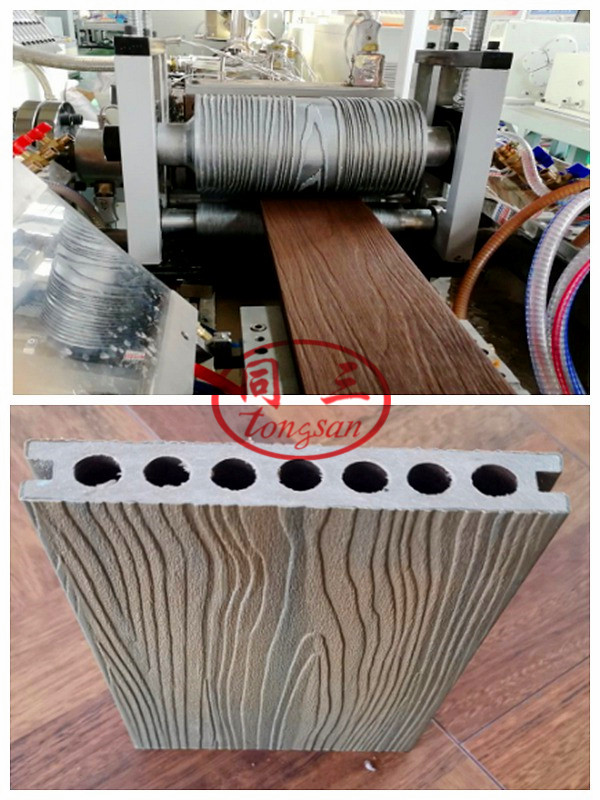

Final product | WPC decking, WPC wall cladding, WPC pergola profile, WPC fence profile, and other WPC construction profiles |

|

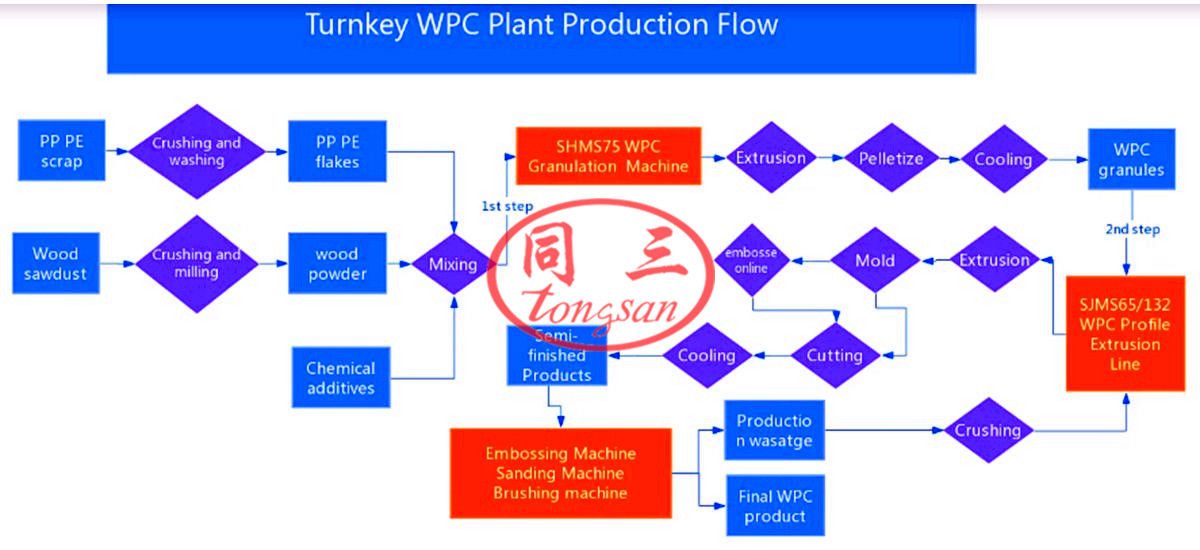

Production process

|

raw material--mixing--granulation--extrusion and molding--surface treatment

|

We have many WPC machine in stock for sale. fast delivery is avaliable

|

Project size

|

Smallest plant

|

Growing plant

|

Most effective plant |

Ideal plant

|

|

Project machine FOB cost

|

80000-100000 USD

|

130000-170000 USD

|

250000-340000 USD |

360000-500000 USD

|

|

Project capacity

|

1500 kgs per day

(24 hours running) |

3000 kgs per day

(24 hours running) |

9000 kgs per day (24 hours running) |

18000 kgs per day

(24 hours running) |

|

Project factory size

|

300 m2

|

500 m2

|

1000 m2 |

2000 m2

|

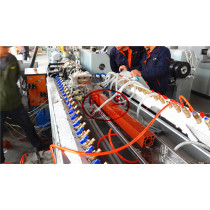

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile.

The WPC profile adopts two-step production process.The first step is using WPC granulating machine to make WPC pellets from recycled PP/PE material,wood powder and chemical additives.The max wood percentage can be 70%.The the WPC profile extrusion line will make the WPC pellets into WPC profiles by equip customized mold.We can equip on-line embossing machine to achieve 3D wooden pattern.

The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

these machines is for making WPC products with better wooden feeling design.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram