70% wood with 30% HDPE WPC Wall Cladding Extrusion Line Machine

group namePP PE WPC Profile Machine

-

Min Order1 piece

brand nametongsan

modelSJ65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeMon, 26 Oct 2020 10:35:36 GMT

Paramtents

Plastic Material PE/PP Recycled Plastic Material

Wood Material Wood Sawdust/Rice Husk/Straw/Cotton Straw

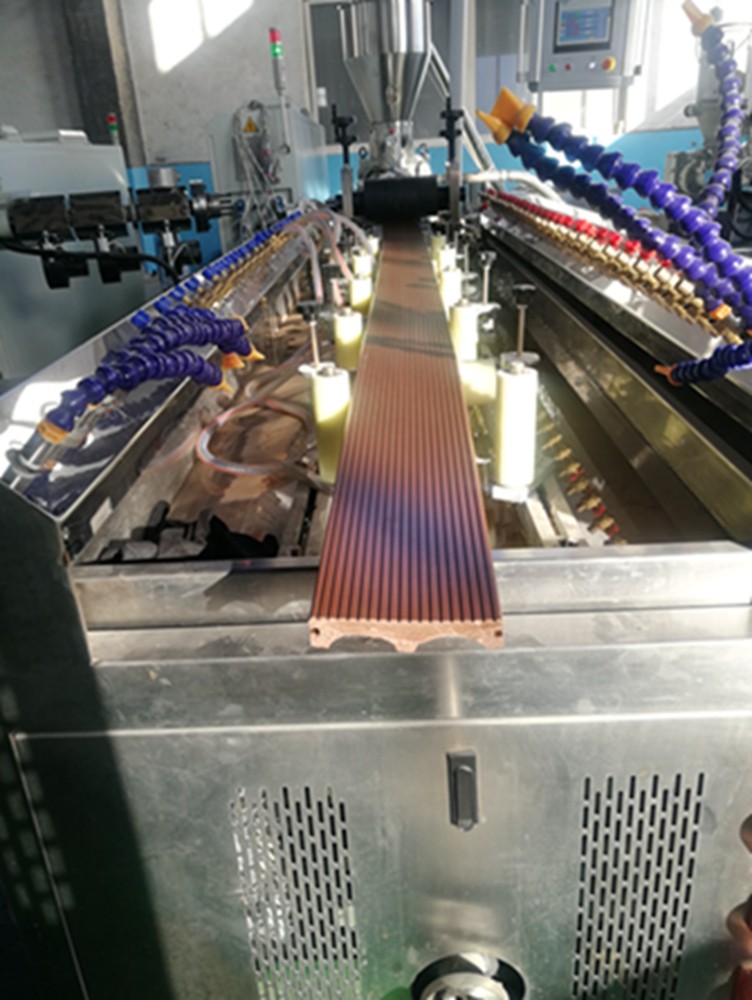

Processing Mixing, Granulating, Extrusion

Mchine WPC Wall Cladding Machine

Packging & Delivery

Min Order1 piece

Briefing

ECO friendly

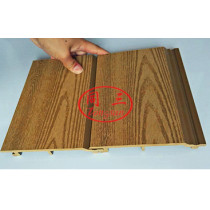

finish product: decking, pergola, fence, chair,wall...

Detailed

|

Plastic material

|

recyccled PP/PE plastic

|

|

Wood material

|

wood powder from rice husk/straw,wheat husk/straw,wood sawdust,wastage wood

|

|

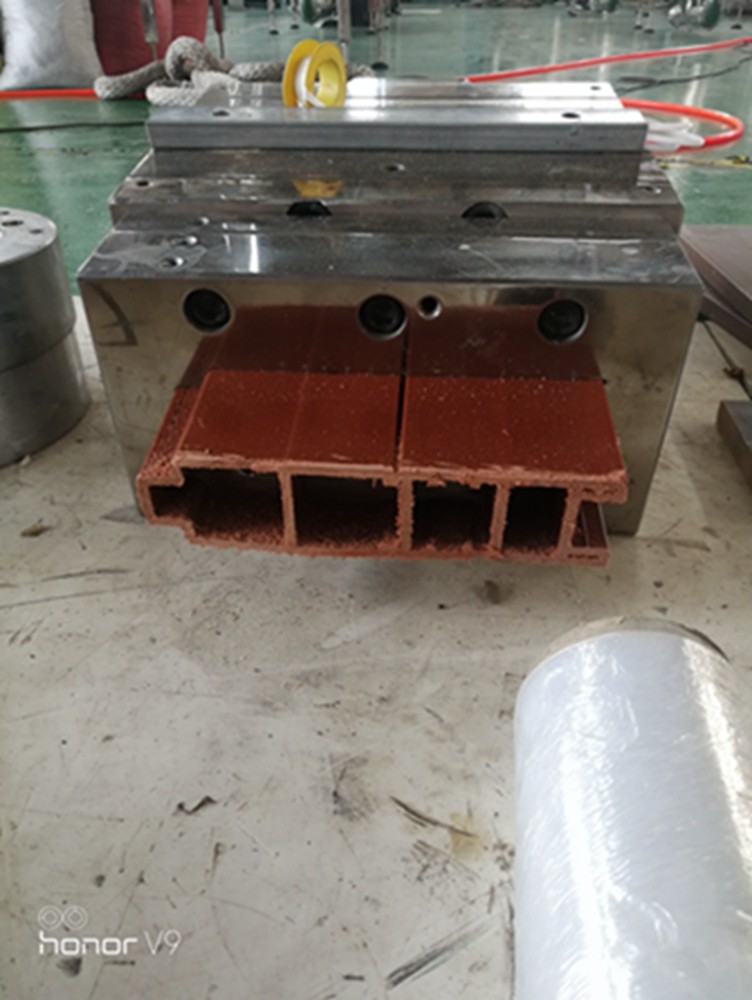

Percentage of plastic

|

25-30%

|

Percentage of wood powder | 50-70% |

Final product | WPC decking, WPC wall cladding, WPC pergola profile, WPC fence profile, and other WPC construction profiles |

|

Production process

|

raw material--mixing--granulation--extrusion and molding--surface treatment

|

|

material

|

WPC granules made by WPC granulation machine |

|

plastic percentage

|

20-30% recycled PP/PE |

|

wood percentage

|

60-70% wood powder (made from rice husk,rice straw,cotton straw, wood sawdust, wood branch, wheat husk, wheat straw....) |

|

chemical

|

5%-10% Chemicals: Coupling agent, PE wax, Stearic acid, CaCo3, pigments, Anti UV agent, Anti Oxygen agent |

|

moisture

|

less than 6% |

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram