hollow solid wpc door jamb making extrusion machine production line supplier

group namePVC WPC Profile machine

-

Min Order1 piece

brand nametongsan

modelSJ65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeTue, 01 Dec 2020 13:52:59 GMT

Paramtents

Machine Type wpc door jamb machine

Material PVC with wood and chemical

Product Width Customerized

Extruder Size SJ51/105 65/132 80/156

Production Speed 0.5-5m/Min

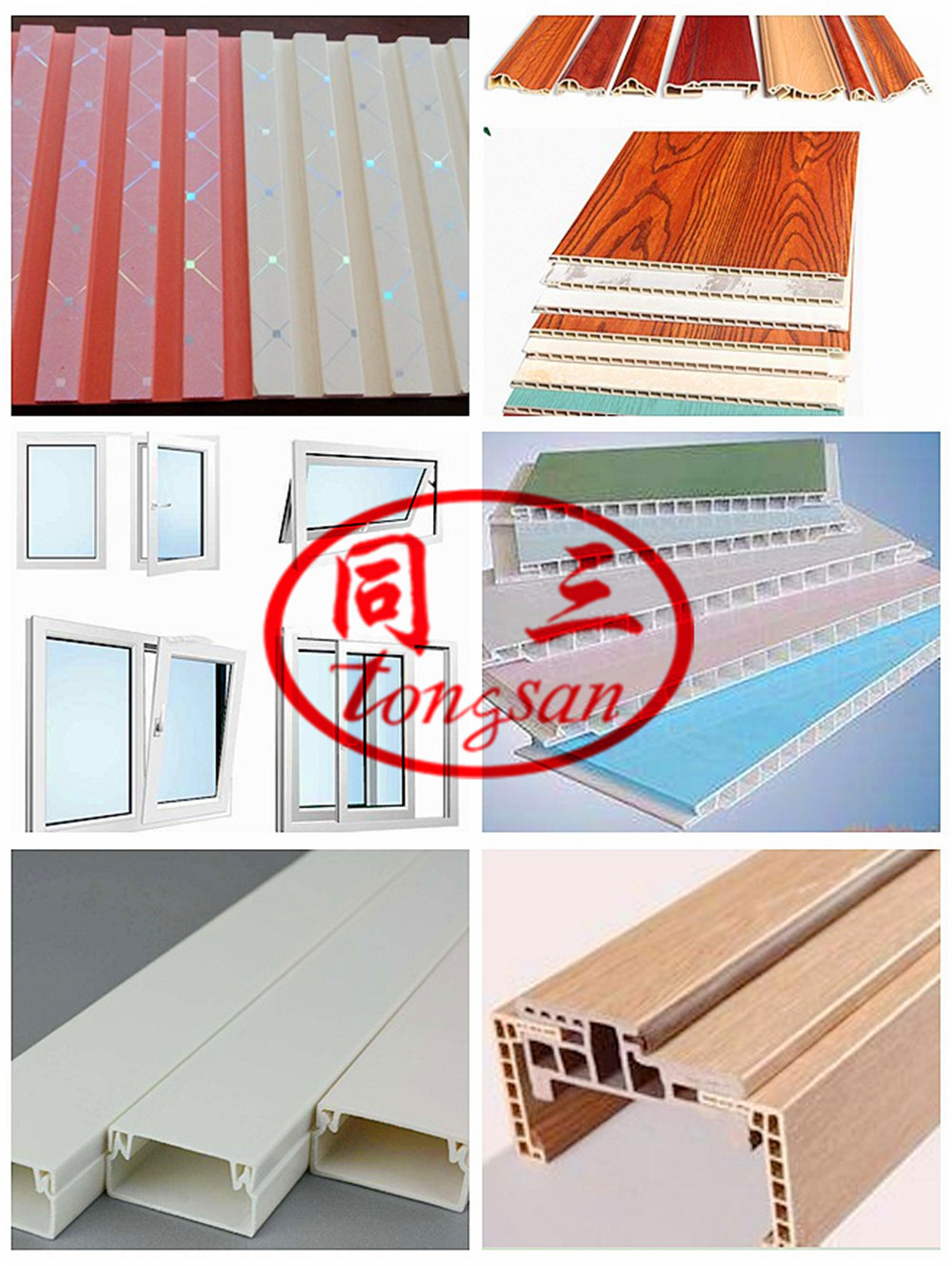

Product Ceiling,Wall,Skirting,Window,Door Frame

Packging & Delivery

Min Order1 piece

Briefing

2. size customerized

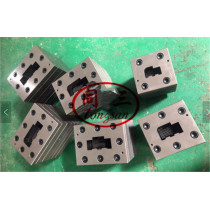

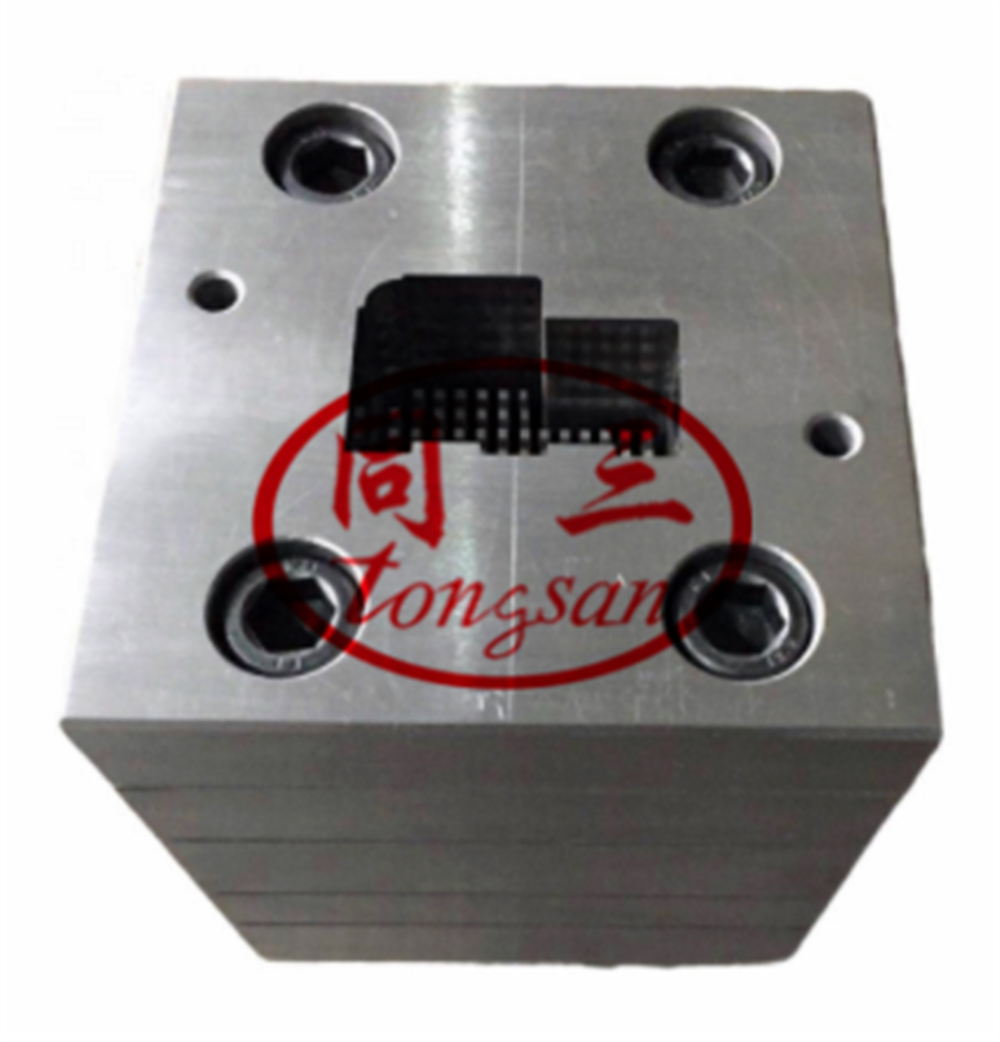

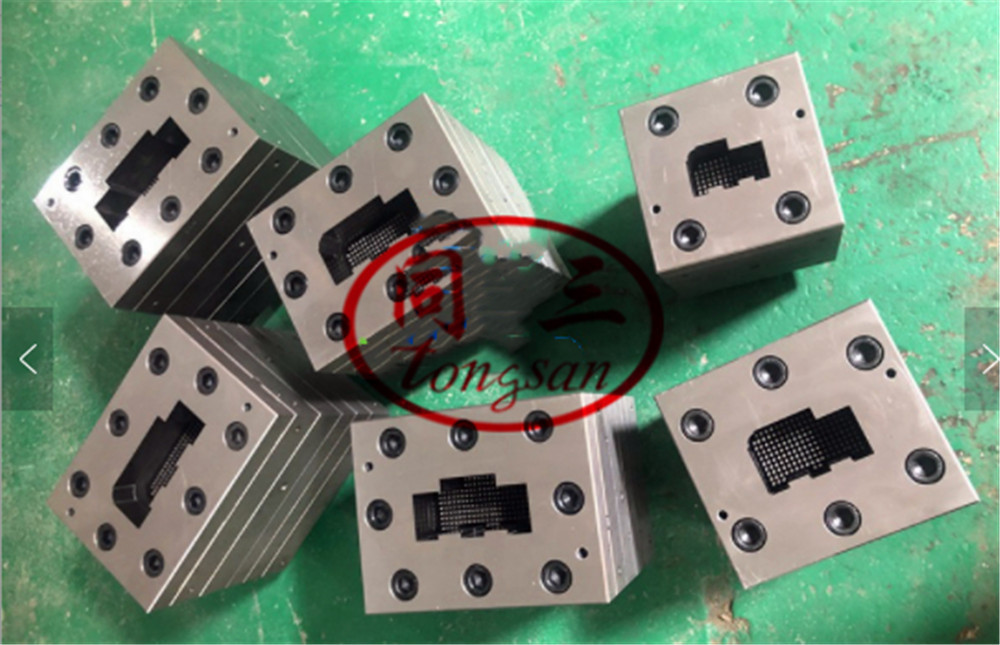

3. mold is 3Cr17 high quality material

4. surface can do lamination

Detailed

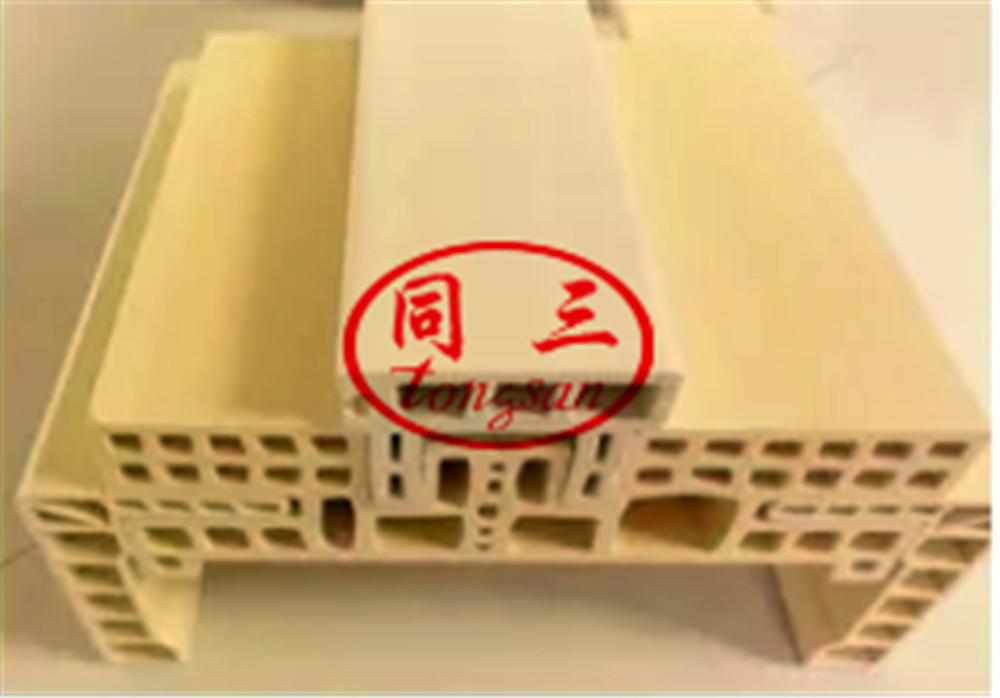

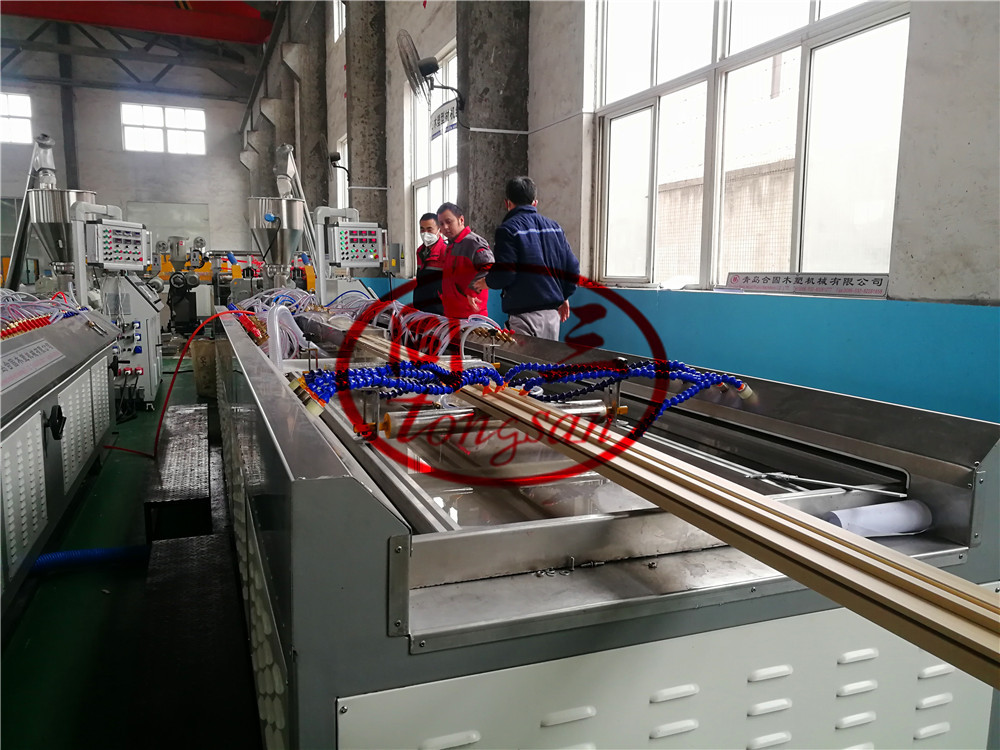

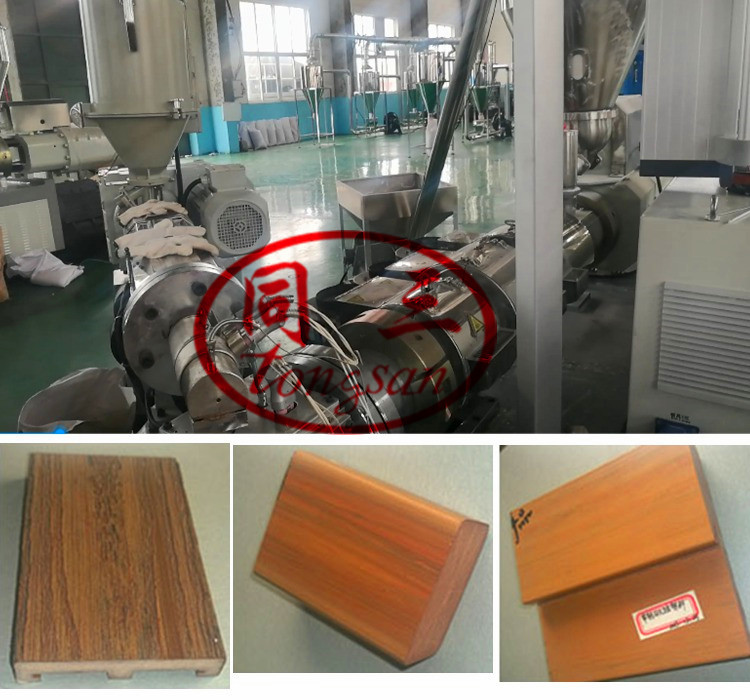

Solid WPC door jamb making machine uses PVC and wood powder as raw material, mixing with CaCo3 and chemical additives, for making WPC door frame with solid profile mold.

the solid WPC door jamb mainly size: 75*45mm, 100*50mm, 100*62mm, 125*62mm, 150*62mm, 175*62mm.

the special designed extruder and mold is adopting solid profile with foaming technology

the product density can be 0.8-1.3 gram/cm3 and adjustable by adjusting the foaming agent and foaming regulator.

|

item

|

machine discription

|

marks

|

|

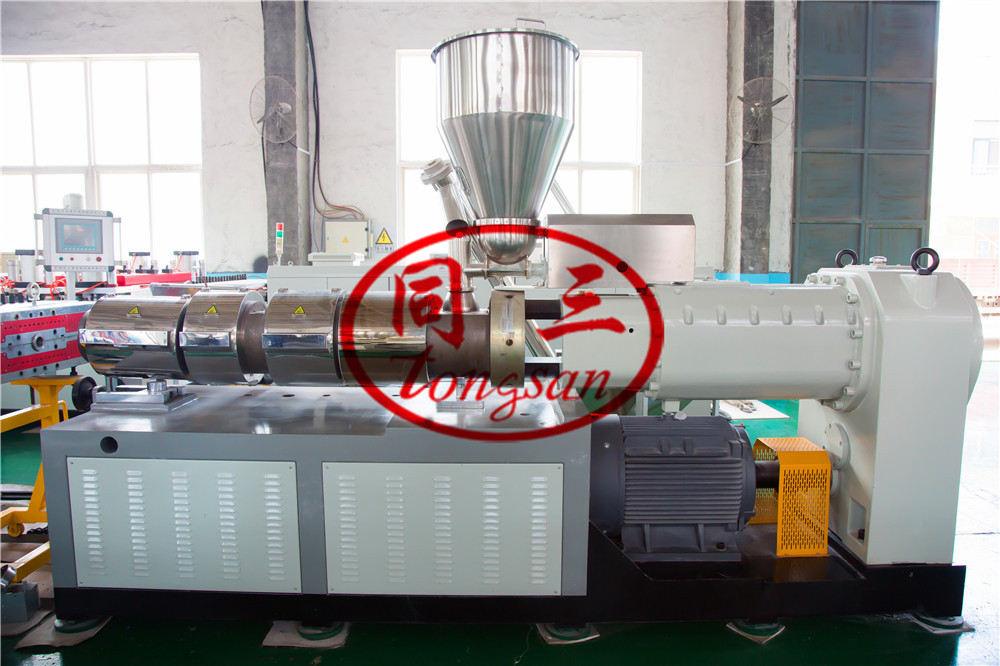

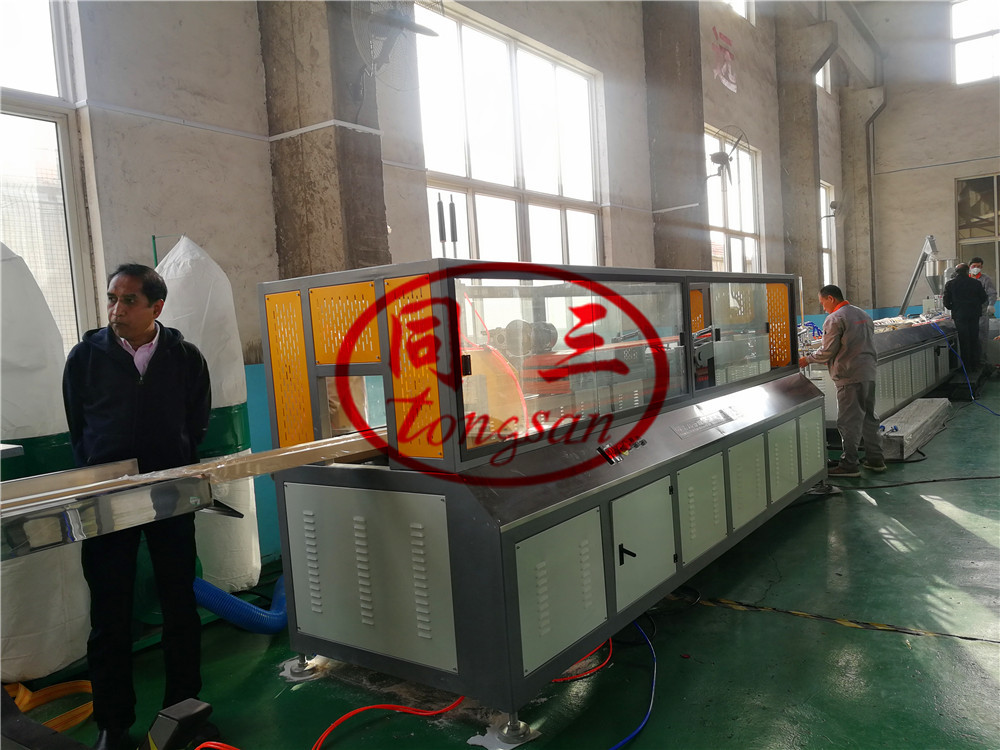

SJSZ65/132 pvc wpc door frame extrusion line

|

auto material loader

|

load material to extruder automatically

|

|

SJSZ65/132 connical double screw extruder

|

mixing and melting material

|

|

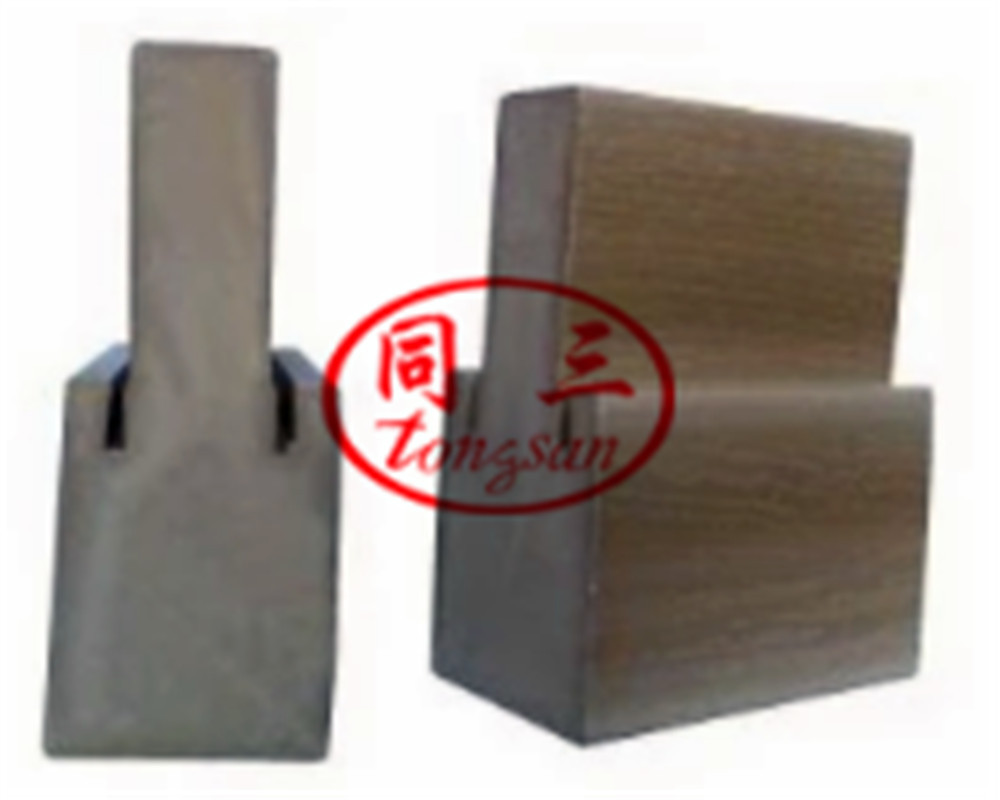

mold: die + calibrating mold + water tank | change mold can get different shape and size | |

vacuum calibrating table 6m/8m/10m/12m | for product forming and cooling | |

haul off machine | double caterpillar | |

cutting machine | fixed length cutting | |

dust collector | collect dust after cutting | |

stacking machine | product stacking | |

auxilary machine | 300/600 mixer | mix all material together |

water chiller | provide chilling water | |

air compressor | provide compressed air | |

wastage recycle machine | 360 crusher | recycle wastage on production to reuse |

500 miller | ||

surface treatment machine | laminating machine | get wooden grain |

ASA co extrusion |

motor: SIEMENS

inverter: ABB

temperature controller: SIEMENS

Calibrator size: 240mm or 320mm

Quantity of calibrator section:1 or 2 or 3 or 4 sets according to product size shape

Water tank length: 2000mm or 4000mm, fiber glass board, accessories are made of stainless steel

material of surface: 304 stainless steel

vacuum pump included

water pump included

haul off controlled by ABB inverter

saw blade cutting

dust collector included

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram