Plastic ABS Sheet Co Extrusion Machine Line For Making ABA Three Layer Plastic Sheet

group namePlastic Sheet Machine

-

Min Order1 piece

brand nametongsan

modelSJ90 SJ110 SJ120 SJ130 SJ150

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeMon, 28 Dec 2020 13:32:37 GMT

Paramtents

sheet width 1000-2600mm customerized

sheet material PP PE ABS HIPS PMMA

sheet thickness 1-6mm

company Qingdao Tongsan Plastic Machinery

Packging & Delivery

Min Order1 piece

Briefing

width max 2000mm,thickness is 1-20mm

Detailed

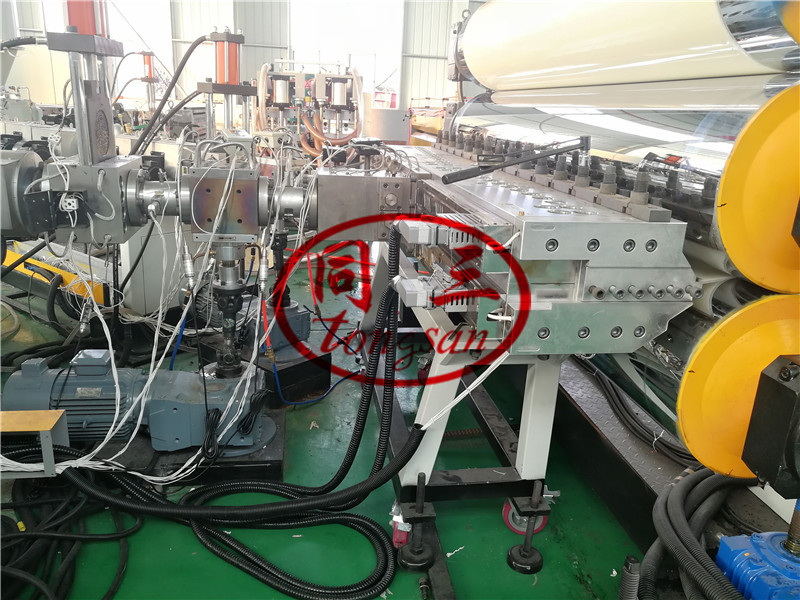

1,Plastic sheet extrusion line is capable of continuously producing mono-layer or multi-layer PVC/PP/PE/ABS/PMMA/PC/PS/HIPS plate and sheet with the width less than 3000mm and thickness of 0.25-30mm . The products are widely used in the fields of refrigerater ,air conditioner ,auto,advertisement ,and construction ,environment protection ,etc.

2, Plastic sheet extrusion line includes many equipments ,such as :extruder ,screen changer and mould,three-roller calendaring machine,bracket of cooling roller,landscape orientation cutting machine and the winder.

|

item

|

machine name |

quantity

|

|

1

|

Raw material drying device |

one set

|

|

2

|

Material auto feeding |

one set

|

3 | High output Single screw extruder | two sets |

4 | Melt dosing pumps and hydraulic screen changer | two sets |

5 | Co-extrusion Mold & Distributor | one set |

6 | Three-roller calendaring machine | one set |

7 | Cooling bracket | one set |

8 | Hauling off device | one set |

9 | Cutting device | one set |

|

10

|

Stainless steel stacker |

one set

|

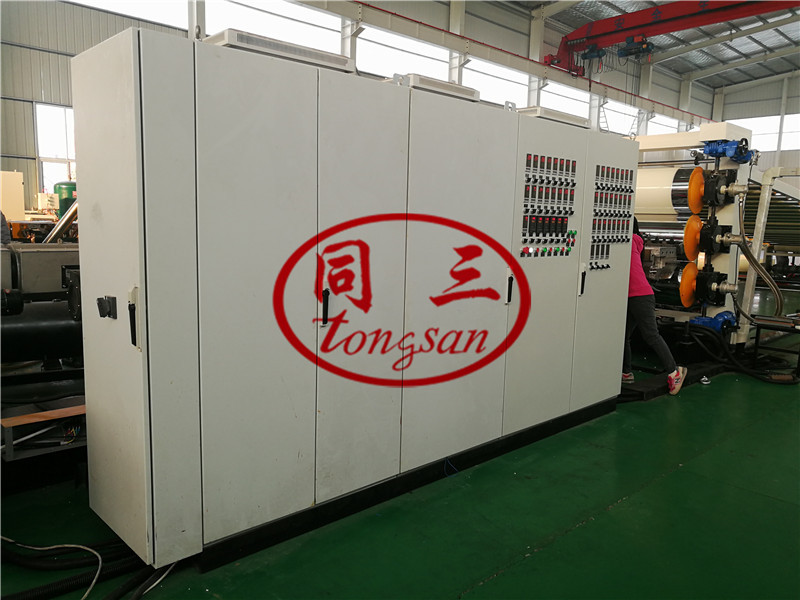

11 | Electricity control system | one set |

and advanced temperature controlling system ensure the good plasticization, high output and stable extruding.

Mold for Plastic sheet extrusion machine

The quick screen changer of hydraulic system ensures the short course of screen changing without material-leakage. Reasonable structure of mould should be chosen in terms of material, whereas moulds of clothes-rack mode are widely accepted to regulate flow-distribution and guarantee even thickness of plates (sheets).

Three roller calendaring machine for Plastic sheet extrusion machine

Inclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets). Temperature controller operates separately and gap among the three rollers can be adjusted freely, and the central roller has special design of regulating angle. Both ensure the excellent calendaring effect and even thickness of plates (sheets).

Cooling bracket for Plastic sheet extrusion machine

Equipped with corresponding guide roller, the cooling effect is better. In addition, the edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge.

Haul off machine for plastic sheet extrusion machine

Double roller haul off machine

Roller material: rubber

roller up and down: by cylinder control

Speed control: Frequency

Cutting machine for Plastic sheet extrusion machine

It is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance.

Stacker for Plastic sheet extrusion machine

Stacker width: according to sheet width

Stacker length: 3 meters

Stacker material: stainless steel

Stacker type: automatically

electricity control cabinet for plastic sheet extrusion machine

Motor: Siemens motor

Inverter: ABB inverter

Temperature control: Omron brand

Contractor: Schneider

PLC control: Siemens brand computer touch screen

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram