PP polypropylene twin wall corrugated hollow sheet board extrusion line machine

group namePlastic Hollow Corrugated Sheet Machine

-

Min Order1 piece

brand nametongsan

modelSJ100/36 SJ120/36 SJ150/36 SJ80/36

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeSun, 13 Dec 2020 09:27:16 GMT

Paramtents

material pp with masterbatch

screw type single screw high efficiency

screw material 38 Crmoala

cooling water

screw LD 36:1

application packing, turnover box

Packging & Delivery

Min Order1 piece

Briefing

Detailed

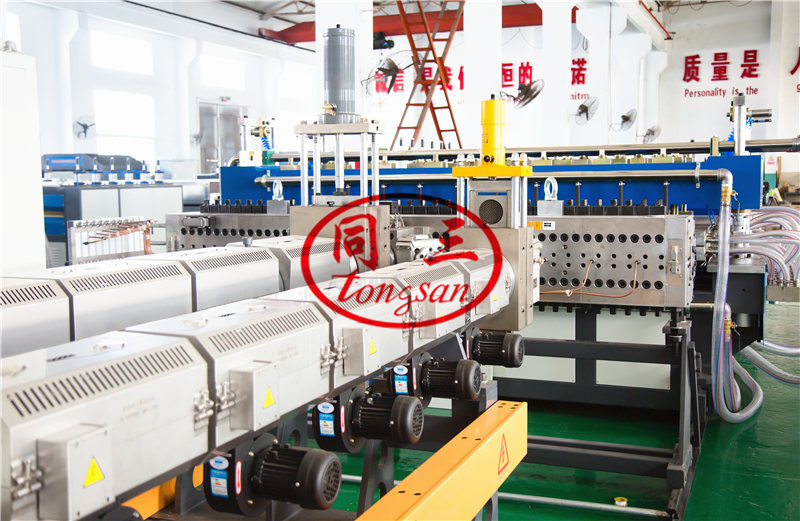

Qingdao Tongsan Plastic Machinery Co.,Ltd is one experienced plastic machinery manufacutrer since 1997.

PP Corrugated Sheet Extrusion Line is one of our advantage machine,

we also provide downstream machines for PP corrugated sheet printing, cutting cutting, Box making .

Our Motto

Quality is the style of TONGSAN.

Credibility is the personality of TONGSAN.

Innovation is the pursit of TONGSAN.

PP corrugated sheet extrusion line

Machine model and Technical parameter

|

Model |

Sheet width |

Sheet thickness |

Extruder Model |

Motor Power |

|

TS-1400 |

1250mm |

1.5-12mm |

100/36 |

55-75kw |

|

TS-1800 |

1700mm |

1.5-12mm |

120/36 |

75-90kw |

TS-2300 | 2150mm | 1.5-12mm | 120/36 | 90-110kw |

TS-2600 | 2450mm | 1.5-12mm | 120/36 | 90-110kw |

TS-3000 | 2800mm | 1.5-12mm | 150/36 | 132kw |

PP hollow sheet making machine /plastic corrugated sheet production line

This PP hollow corrugated sheet making machine production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging.

PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box.

It is characterized by light weight, high intensity, dampproof, and anticorrosion.

The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

PP polypropylene twin wall corrugated hollow sheet board extrusion line machine details:

No |

Machine name |

Quantity |

1 |

Material mixing machine |

1 set |

2 |

Single screw extruder |

1 set |

3 |

Single screw co-extruder |

1 set |

4 | Screen changer | 1 set |

5 | Co-extruder mold:ABA | 1 set |

6 | Calibrating machine | 1 set |

7 | Six-pairs haul off machine 1st | 1 set |

8 | Preheating Oven | 2 sets |

9 | Cooling device | 1 set |

10 | Corona treatment device | 1 set |

11 | Edge cutting device | 1 set |

12 | Second Haul-off Equipment | 1 set |

13 | Transverse cutting machine | 1 set |

14 | Stacker | 1 set |

Extruder for PP corrugated sheet extrusion line

The specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding.

1, auto spiral screw feeder

2, drying hopper

3, siemens motor

4, aluminum heater

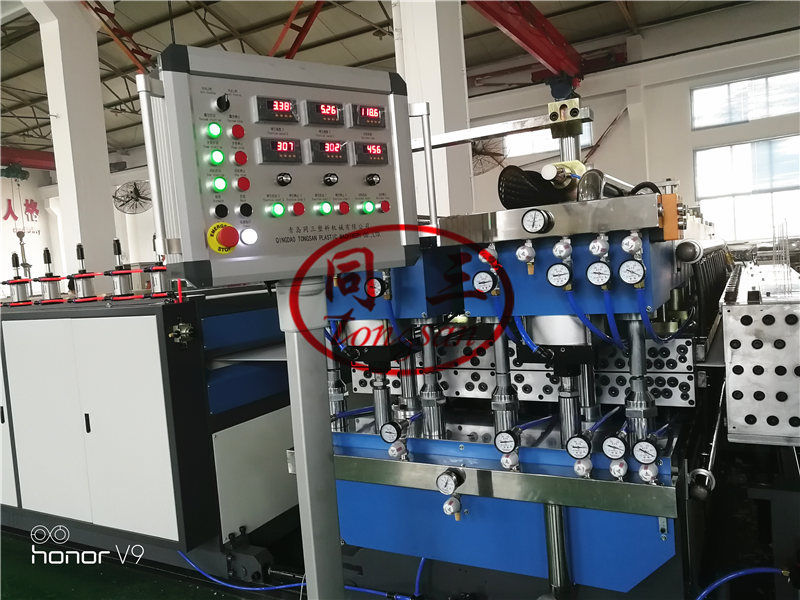

Mould for PP corrugated sheet extrusion line

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

calibrating table for PP corrugated sheet extrusion line

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision.

Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type.

Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

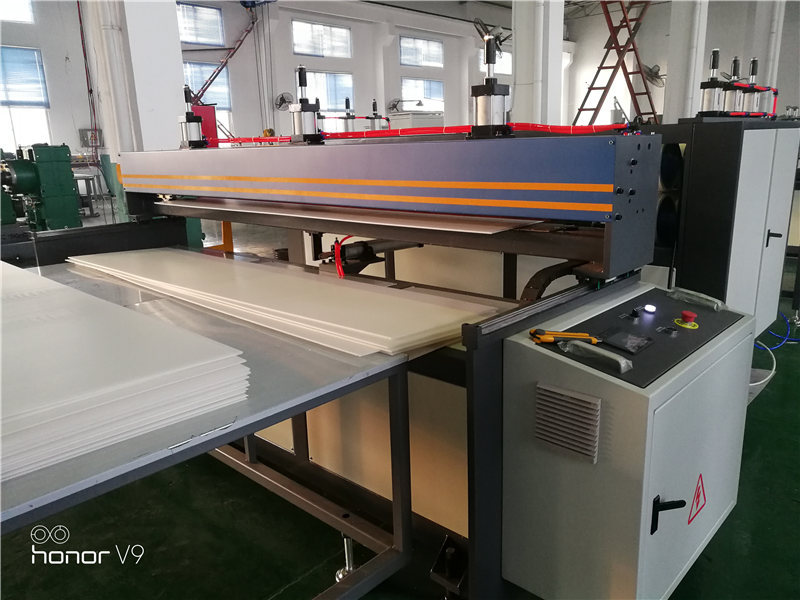

haul off device for PP corrugated sheet extrusion line

There are two tractors.

The first one is high power, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal.

The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

Heating oven for PP corrugated sheet extrusion line

the heating oven device is necessary for the PP hollow sheet to remove the stress of the sheet, the heating oven should be made by 304 stainless steel

the heating oven is equipped with separately temperature control system for each zone to ensure the heating to be uniform, 4 meter lengths of heating oven is necessary,

corona treatment for PP corrugated sheet extrusion line

The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

Auto Cutter for PP corrugated sheet extrusion line

Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

Control cabinet for PP corrugated sheet extrusion line

1, ABB inverter motor

2, Siemens contractor

3, Omron temperature control

4, English button

5, ventilation on each panel

6, number mark on each cable

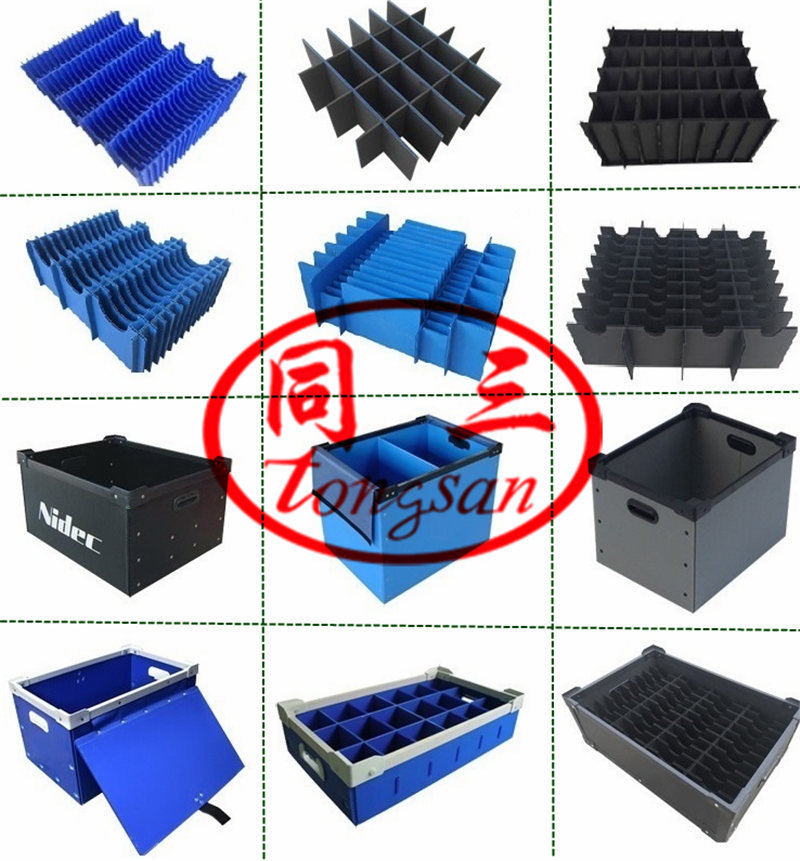

How to make PP packing box from the PP hollow corrugated sheet?

PP hollow sheet turnover box main material is a PP hollow sheet, and then after the pressure cut, torn edges, stitching, assembly and made of a series of processing flow.

|

Item |

PP packing box making Machine |

Note |

|

1

|

Material Mixing machine |

For mixing material, such as chemicals, color masterbatch, filling masterbatch, recycle material |

|

2

|

PP hollow corrugated sheet extrusion line |

For makeing Pp hollow corrugated sheet for required width and thickness. width: 1200-2700mm thickness: 2-12mm |

|

3

|

PP hollow sheet die cutting machine |

For cutting the Pp sheet into required shape for folding box |

4 | PP hollow sheet printing machine | for printing logo and designs on the Packing box, there is different printing machine, such as single color printer, double color printer, four color printer. |

5 | PP hollow sheet welding machine | For folding the Pp hollow sheet into required box shape, welding machine and bookbinding machine both can work for it |

6 | PP hollow sheet bookbinding machine |

1, PP hollow corrugated sheet extrusion line

2, Die cutting machine for making required shape and size for pp packing box production

3,PP box printing machine

we also can design die cutting and printing machine in an automatic production line.

it shall include PP hollow sheet auto feeder--- PP hollow sheet auto printing--- PP hollow sheet auto die cutting---PP hollow sheet auto convey---PP hollow sheet auto stacker

4, stitching the two sheets by rivets, flat wire or welding, etc., the stitching seal can be sealed by fiber tape or glue or magic paste.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram