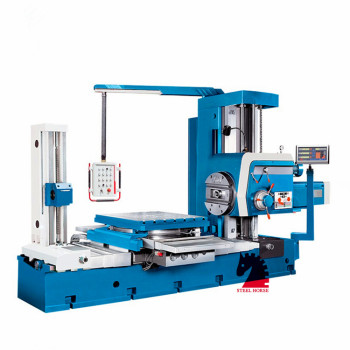

CNC or normal TPX6111 TPX6113 vertical horizontal milling and boring machine

- US $200000.00

1 - 1 piece

- US $180000.00

2 - 2 piece

- US $180000.00

3 - 3 piece

- US $180000.00

4 - 4 piece

- US $180000.00

5 - 5 piece

group nameboring machine

-

Min Order1 piece

brand namesteel horse

modelTPX6111B TPX6111 TPX6113

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal

-

update timeTue, 14 Jan 2020 13:42:00 GMT

Paramtents

CNC or Not CNC or normal

Warranty 2 Years

Packging & Delivery

Size400cm x300cm x400cm

Weight10000kg / piece

Min Order1 piece

Briefing

Detailed

S.N | Free Std Accessories Name | Remark |

1 | Rear column | 1 Set |

2 | Face heading plate | 1 Set |

3 | Tool holder for boring | 1 pc |

4 | Tool holder for milling | 1 pc |

5 | Operation tools | 1 Set |

6 | Automatic centralized lubrication system | 1 Set |

7 | Work light | 1 Set |

8 | Documents in English | 1 Set |

Item | Unit | TPX6111B | TPX6111B/2 | TPX6111B/3 | TPX6113 | TPX6113/2 | |

spindle | Boring spindle diameter | mm | 110 | 110 | 110 | 130 | 130 |

Spindle taper | - | Morse No 6(ISO7:24 50#) | Morse No 6(ISO7:24 50#) | Morse No 6(ISO7:24 50#) | Metric 80(ISO7:24 50#) | Metric 80(ISO7:24 50#) | |

Max. spindle torque | N.m | 1225 | 1225 | 1225 | 3136 | 3136 | |

Max. spindle thrust | N | 12250 | 12250 | 12250 | 31360 | 31360 | |

Number of spindle speed | - | 22 | 22 | 22 | 24 | 24 | |

Range of spindle speed | r/min | 8-1000 | 8-1000 | 8-1000 | 4-800 | 4-800 | |

Power of main motor | kW | 7.5 | 7.5 | 7.5 | 15 | 15 | |

Facing head | Max. facing head torque | N.m | 1960 | 1960 | 1960 | 4900 | 4900 |

Facing head diameter | mm | 600 | 600 | 600 | 750 | 750 | |

Range of facing head speed | r/min | 4-200 | 4-200 | 4-200 | 2.5-125 | 2.5-125 | |

Number of facing head speed | - | 18 | 18 | 18 | 18 | 18 | |

Table working | Table working surface(L*W) | mm | 1100*960 | 1100*960 | 1250*1100 | 1600*1400 | 1800*1600 |

Max. permissible load on table | kg | 2500 | 2500 | 3000 | 8000 | 10000 | |

T-slot size | mm | 22*7 | 22*7 | 22*7 | 28*9 | 28*11 | |

Range of working | max. travel of x axis | mm | 900 | 1250 | 1600 | 1600 | 2000 |

max. travel of Yaxis | mm | 900 | 900 | 1200 | 1400 | 1800 | |

max. travel of Z axis | mm | 1400 | 1400 | 1400 | 2000 | 2000 | |

Max. traverse of boring spindle | mm | 600 | 600 | 600 | 900 | 900 | |

Travel of facing slide | mm | 180 | 180 | 180 | 250 | 250 | |

Table working change | 360 | 360 | 360 | 360 | 360 | ||

Distance between spindle to table surface | mm | 0-900 | 0-900 | 0-1200 | 0-1400 | 0-1800 | |

Feed | Rapid speed | mm/min | 2500 | 2500 | 2500 | 2500 | 2500 |

Range of spindle, headstock and table feeds per speed | mm/rev | 0.04-6 /0.01-1.88 | 0.04-6 /0.01-1.88 | 0.04-6 /0.01-1.88 | 0.04-6 /0.01-1.88 | 0.04-6 /0.01-1.88 | |

Accuracy | Positioning accuracy | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

Positioning accuracy | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

Overall dimensions (L*W*H) | mm | 4910*2454*2750 | 4910*2870*2750 | 5120*3380*3100 | 6995*3647*3442 | 7030*4665*3800 | |

Net weight | kg | 13000 | 14500 | 18000 | 24500 | 29300 | |

The TX series horizontal milling and boring machines are based on a classic design, suitable for rough and finished boring, capable of milling large and box type components. They excel at inner hold boring, cylindrical turning and grooving by radial feed of facing plate. A 4*90 optical positioning device allows for machining accuracy when turning large pieces. The precision digital read out measurement systems ensure accuracy of coordinates and lineation.

1. Bed: Our high quality castings feature polished and hardened guideways. The castings are internally reinforced to maximize rigidity and stability.

2. Control Panel: Available in hanging or swing-arm arrangements, the control panel is easy to use and reduce operator fatigue.

3. Internal Design: Easy to install, steady, and precise with a fully-enclosed structure to prevent oil, coolant, and chip intrusion.

4. Control System: PLC

5. Column: Made of high quality castings with ground and hardened guideways, the optimized structural design easily supports the assembly.

6. Protective Enclosure: Welded high quality steel plates form an excellent protective cover.

7. Hydraulic System: Pressure adjusted via relief value. Variable speed achieved via a rotary value.

8. Headstock: Primary speed is controlled via switches on the headstock itself, a variety of rotational speeds are possible.

· rigid, hardened and precision-ground square guides ensure many years of accurate operation

· mechanical functions that may not be run simultaneously are provided with interlocks

· headstock and feed gears are equipped with an overload clutch

· lever-operated shift gears for positioning of the wheels in the desired position

· Faceplate and drill spindle with different task-specific speed ranges according to the various functions

· table rotates 360째

· telescoping steel cover protects the guides from chips and dirt

· BO 110 incl. tailstock

You need a product

You May Like

6YRS Steel horse machine Co., Ltd.

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow