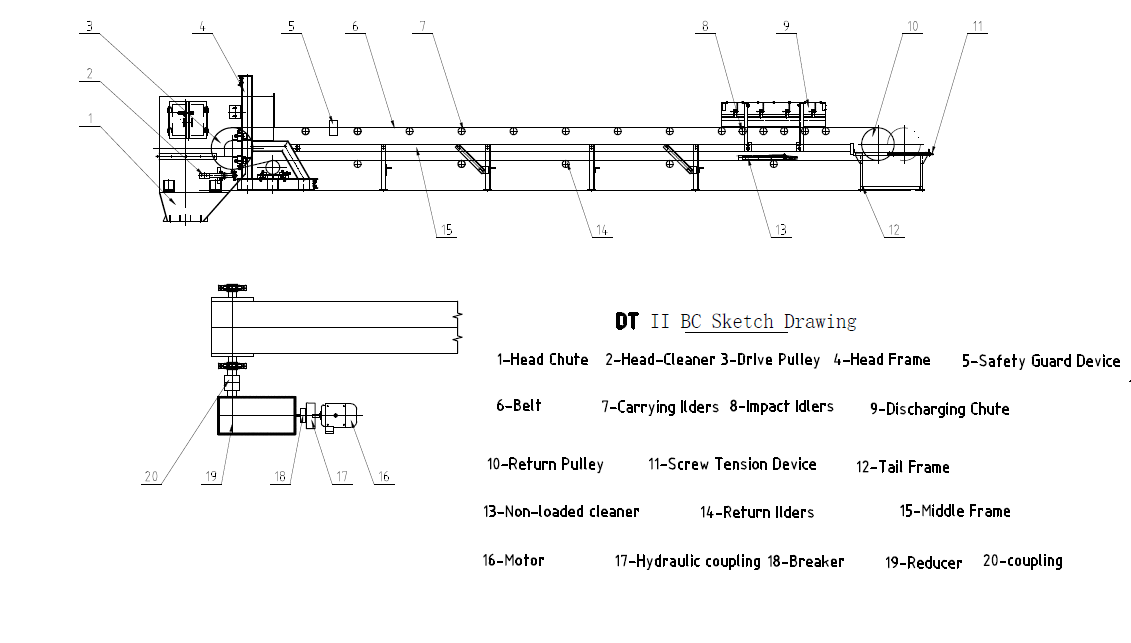

DTII Type Fixed Belt Conveyor used in metallurgy, mines, coal, power station, building materials

group nameFixed Belt Conveyor

-

Min Order1 set

brand nameSKE

modelB500/B650/B800/B1000/B1200/B1400/B1600

payment methodL/C, T/T

-

update timeWed, 16 Jun 2021 09:21:47 GMT

Paramtents

Color Customized

Application aggregate/ mix batch plant/ grain/coal etc

Packging & Delivery

Min Order1 set

Briefing

Detailed

Width | Capacity IV (m3h) |

|||||||||||

Speed V (m/s) |

||||||||||||

0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | 4.0 | (4.5) | 5.0 | (5.6) | 6.5 | |

500 | 69 | 87 | 108 | 139 | 174 | 217 | -- | -- | -- |

-- |

-- |

-- |

650 | 127 | 159 | 198 | 254 | 318 | 397 | -- | -- | -- | -- | -- | -- |

800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | -- | -- | -- | -- | -- |

1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | -- | -- | -- | -- |

1200 | -- | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2674 | 2971 | -- | -- |

1400 | -- | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 3718 | 4130 | -- | -- |

1600 | -- | -- | -- | -- | 2186 | 2733 | 3444 | 4373 | 4920 | 5466 | 6122 | -- |

1800 | -- | -- | -- | -- | 2795 | 3494 | 4403 | 5591 | 6291 | 6989 | 7829 | 9083 |

2000 | -- | -- | -- | -- | 3470 | 4338 | 5466 | 6941 | 7808 | 8676 | 9717 | 11277 |

2200 | -- | -- | -- | -- | -- | -- | 6843 | 8600 | 9776 |

10863 |

12166 |

14120 |

You need a product

You May Like

- Nearest port for product export

- Shanghai,China

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union