ACMAN 2000CMH/1200CFM Industrial Cartridge Dust Collectors Unit Machine for Dust Removal-TR-20B-J

group nameHVAC Dust Collector

-

Min Order1 set

brand nameACMAN

modelTR-20B-J

payment methodT/T

-

update timeSat, 06 Dec 2025 00:34:05 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

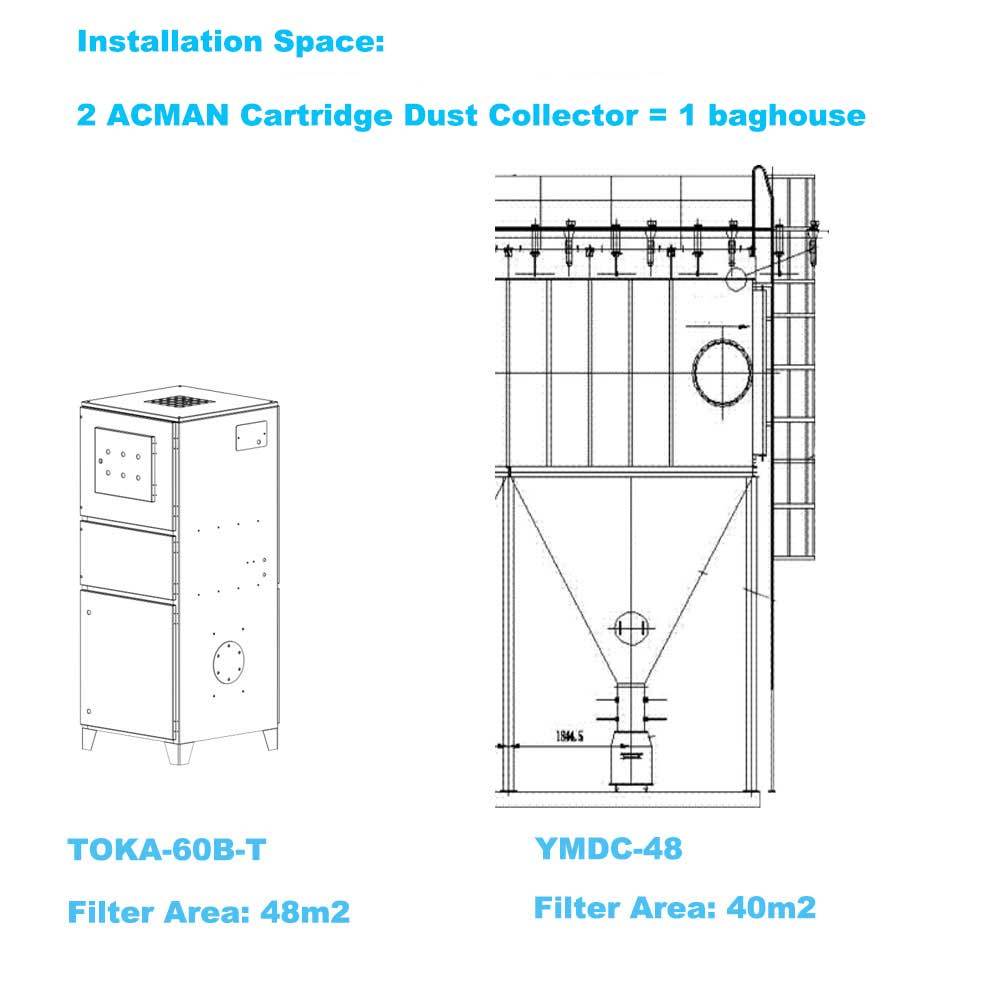

Model (B) | Air volume (m³/h) | Filter Area (m³) | Fan pressure (Pa) | Power (kw) | Air Source (Mp) | Sound (dB) |

TOKA-8B-J | 500-900 | 12 | 1780 | 0.75 | 0.4-0.6 | 65 |

TOKA-10B-J | 900-1100 | 12 | 2040-1780 | 1.1 | 0.4-0.6 | 67 |

TOKA-15B-J | 1400-1600 | 18 | 2040-1780 | 1.5 | 0.4-0.6 | 70 |

|

TOKA-25B-J |

1688-2476 |

30 |

2150-1820 |

3 | 0.4-0.6 | 73 |

TOKA-30B-J | 2664-3405 | 30 | 2700-2200 | 4 | 0.4-0.6 | 73 |

TOKA-40B-J | 3786-4527 | 36 | 2700-2200 | 5.5 | 0.4-0.6 | 75 |

TOKA-60B-J | 4973-6457 | 48 | 2700-2200 | 7.5 | 0.4-0.6 | 75 |

|

TOKA-80B-J |

7081-8489 |

60 |

2700-2200 |

11 | 0.4-0.6 | 78 |

|

TOKA-100B-J |

8490-10455 |

75 |

2790-2020 |

15 | 0.4-0.6 | 80 |

|

TOKA-120B-J |

10400-13455 |

90 |

2790-2020 |

15 | 0.4-0.6 | 85 |

Item | Unit | ACMAN Pleated Filter Dust Collector | Bag House |

Airflow | m3/h | 10000 | 10000 |

First Investment | USD | Est 12000 | Est 21000 |

Fan Motor Power Consumption | USD/Y | 15kw/h*8h*365days | 15kw/h*8h*365days |

Air Compressor Power Consumption | USD/Y | 30Nm3/h | 90Nm3/h |

Filter Replacement | USD/Y | 1075 | 3320 |

Valve Replacement | USD/Y | 0 | 0 |

Maintenance Labor Cost | USD/Y | 300 | 1500 |

Downtime Cost | USD/Y | 2 Hours | 1 Days Est 2200+ |

3 Year Total Cost | USD | Est 39933 | Est 73669 |

6 Year Total Cost | USD | Est 67866 | Est 126336 |

You need a product

You May Like

6YRS ACMAN ENVIRONMENT CO., LTD

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow