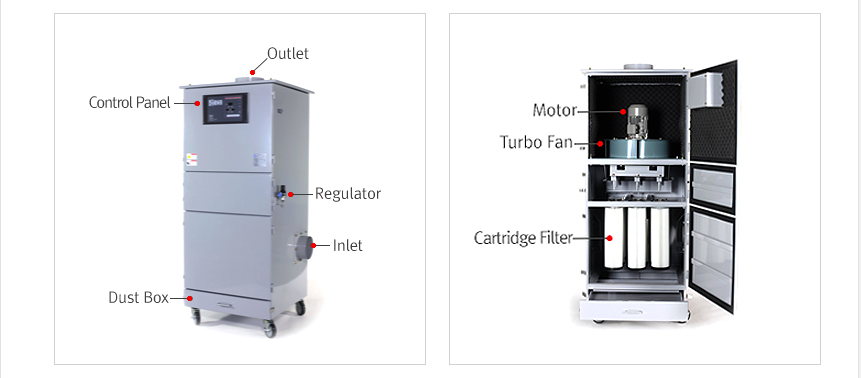

Vertical Capsule Polisher Dust Extractor, Dust Collector for Capsule Polishing Machine, Capsule Polisher Deduster

group namePharmaceutical Dust Collector

-

Min Order1 piece

brand nameACMAN

modelCP-5A

payment methodT/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeWed, 21 Sep 2022 10:43:56 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

6YRS ACMAN ENVIRONMENT CO., LTD

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow