Distillation for water alcohol oil pharma chemical distill China manufacture Amtech distillation

- US $12000.00

1 - 100 piece

group nameDistillation Machine

-

Min Order1 piece

brand nameAmtech

modelAM-DIS

payment methodT/T

-

update timeMon, 06 Jul 2020 14:46:01 GMT

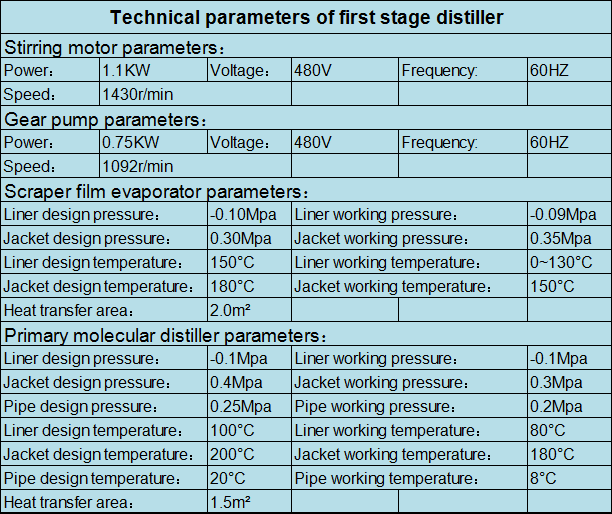

Paramtents

Material Stainless steel 304/316/316L

Usage Pharma/Chemical

Design Customized

Packging & Delivery

Size190cm x 130cm x 172cm

Weight1200.00kg / piece

Min Order1 piece

Briefing

Detailed

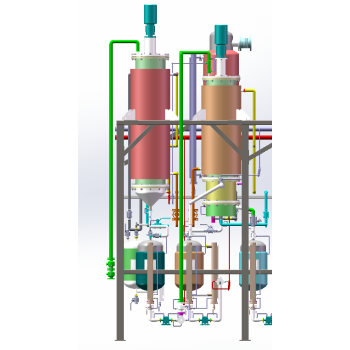

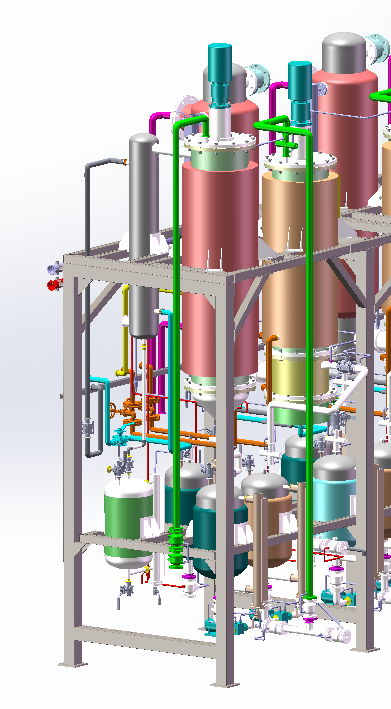

1. It is composed of film evaporator, primary molecular still, external condenser, buffer tank, gear pump, vacuum system, high and low temperature system and water circulation system.

2. The film evaporator and the primary molecular distillation are connected by flange for easy disassembly and cleaning. PTFE scraping film is adopted to make the film thinner and the scraping plate stick to the inner wall of the evaporator.

3. Storage tanks are flanged for easy disassembly and cleaning.

4. The distillation temperature is low. The molecular distillation is operated at a temerature far below the boiling point. As long as there is a temperature difference, the purpose of separation can be achieved.

5. The degree of vacuum is high, and the molecular distillation has a condenser inside, which can liquefy the vaporized vapor phase instantly and shrink the volume, so as to maintain a high vacuum inside the equipment.

6. The evaporation intensity is large, the forced action of the scraper makes the liquid film move downward in a turbulent state, the self-cleaning action of the scraper inhibits the formation of scale layer on the heating surface, increases the heat transfer coefficient and improves the evaporation intensity.

7. Short heating time. As the scraper evaporator is a special falling film evaporator, the material stays on the heating surface for a short time.

8. Operation elasticity is large, unit time into the evaporator material more or less, determines the thickness of the liquid film formed on the heating surface, because the liquid film of the scraper evaporator is forced to form by the scraper, so the amount of feed can be adjusted in a large range, and then can control the light, heavy quality in each component distribution ratio.

9. The degree of separation is higher and molecular distillation can separate substances that are not normally separated easily. So it's especially suitable for handling heat sensitive materials.

10. There is no bubbling phenomenon. Molecular distillation is free evaporation on the surface of the liquid layer under low pressure. There is no dissolved air in the liquid. So in the distillation process it can not make the whole liquid boiling, no bubbling phenomenon.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, EXW

- Acceptable payment methods

- T/T, Westem Union