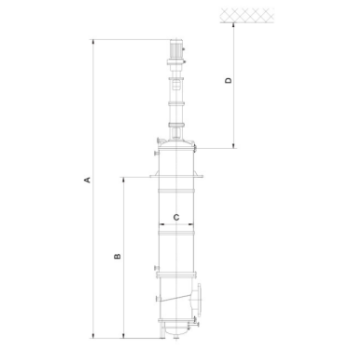

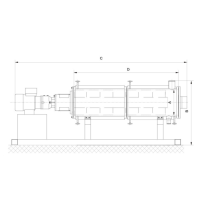

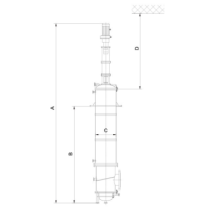

Evaporator Short Path evaporator for pharmaceutical chemical use China manufacture Amtech evaporator

- US $20000.00

1 - 100 piece

group nameEvaporator

-

Min Order1 piece

brand nameAmtech

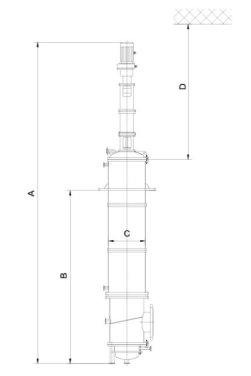

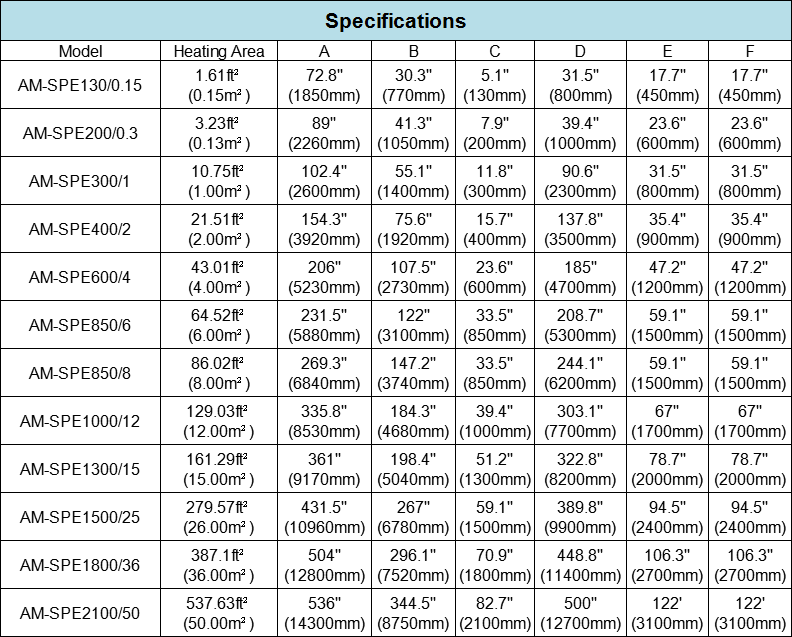

modelAM-SPE

payment methodT/T

-

update timeMon, 06 Jul 2020 14:56:16 GMT

Paramtents

Material Stainless steel 304/316/316L

Usage Pharmaceutical /chemical

Design Customized

Packging & Delivery

Size190cm x 130cm x 172cm

Weight1200.00kg / piece

Min Order1 piece

Briefing

Detailed

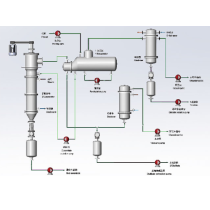

1. Minimum pressure drop allows high vacuum operation and low product temperature. Gentle distillation of thermally sensitive products with short residence times and minimal product retention in the evaporator.

2. Short-path evaporation is very versatile, from high evaporation rate to high vacuum distillation, the vacuum of the heating surface can reach up to 0.001 mbar.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, EXW

- Acceptable payment methods

- T/T, Westem Union