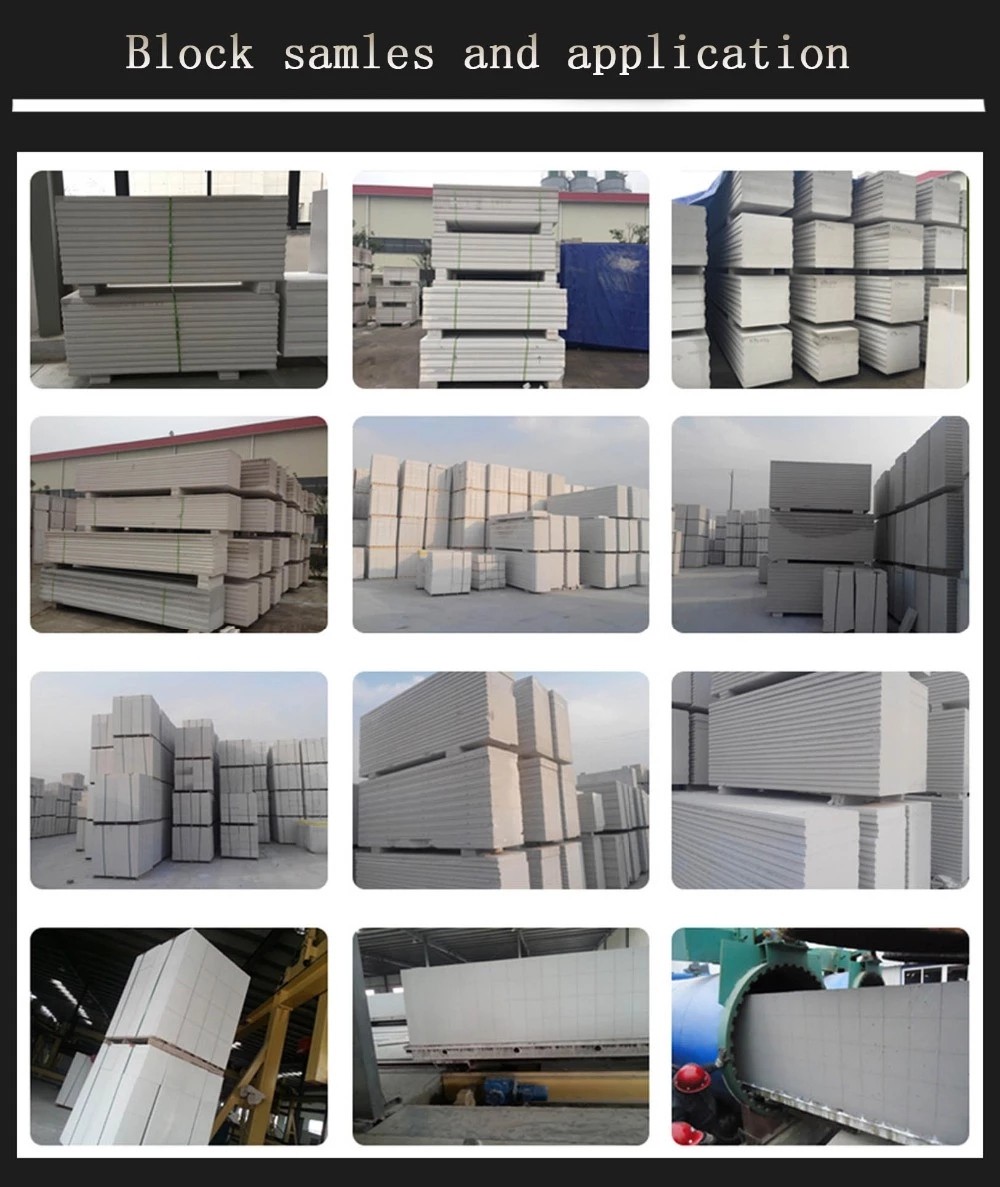

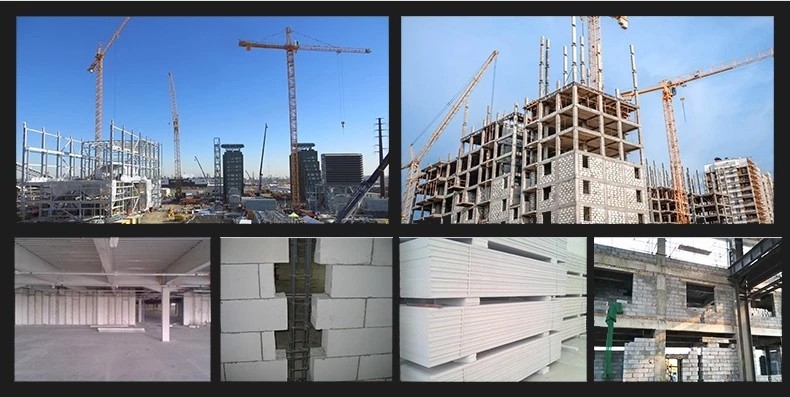

Autoclaved Aerated Concrete Sand Fly Ash AAC Block

group nameALC wall panel Making Machine

-

Min Order1 set

brand nameHummingbird

modelALC-002

payment methodL/C, D/P, T/T

-

update timeTue, 30 Jun 2020 16:32:35 GMT

Paramtents

Type: Aerated autocalved concrete machinery

Brick Raw Material: Sand or fly ash

Place of Origin: Shandong, China

Certification: ISO, CE,BV, SGS, PVOC

Capacity: 300000m3/year

Color: Optional

Packging & Delivery

Min Order1 set

Briefing

Detailed

Technological Standard

1. The technological standard of this project is superior products according to the Chinese national standards. The equipments are made according to Chinese standard and criterion.

2. This project provides the mature tilting technology in China.The products reach the block requirements of grade 04~07 of GB11968-2006.

3. Capacity of AAC making machine: from 30,000 cubic meter to 300,000 cubic meters per year.

4. Equipments: stocking raw materials, mixing, molding, forming, cutting, evaporating and curing, crane cramp, transporting etc.,

5. Material proportion in fly ash type and sand type.

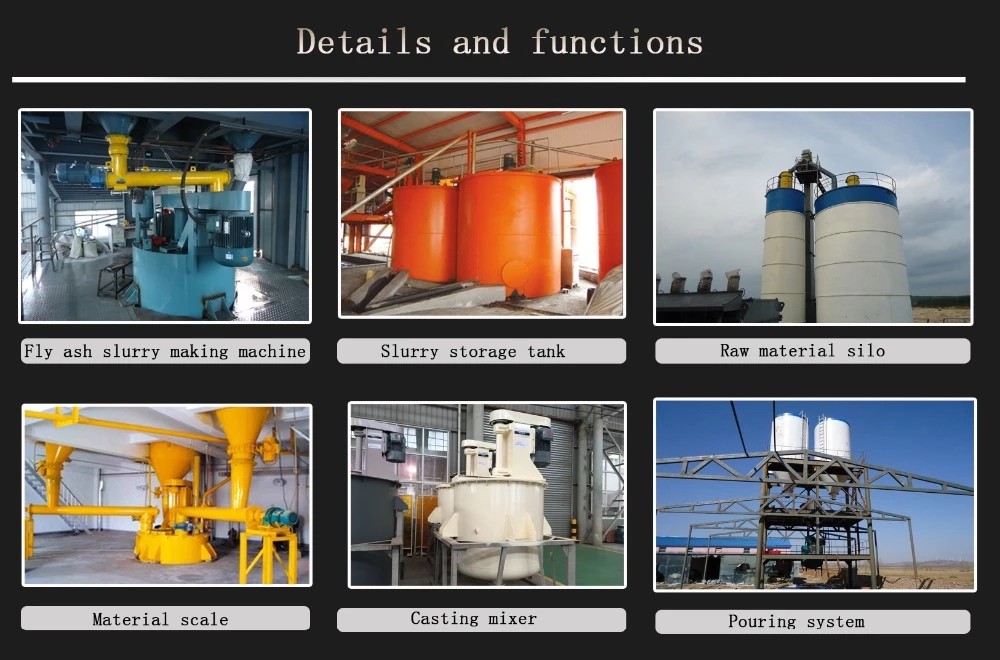

Fly ash slurry making machine: Getting and mixing raw materials such as fly ash and water added into slurry.

Slurry storage tank: To store the slurry stirred and abraded by a pulper or a ball mill.

Raw material silo: To store raw materials such as lime, cement and gypsum.

Material scale: Weighing lime, gypsum, cement powder by powder material scale; weighing slurry by slurry scale.

Casting mixer: Mixing rated lime powder, cement, slurry and aluminium powder evenly.

Pouring system: The various preparedmaterial are measured according to mixing ratio, stirred and poured into the mold. The control system adopts an integrated PLC control system.

Mould box: Pouring the mixed material into mould box for the fermentation of bubble,curing,freezing until demoulding and cutting.

Ferry car: Our company adopts the most advanced stationary casting. Ferry car moves under the casting machine to accept pouring, then moves on the appropriate track into the curing room after pouring is completed.

Curing room: Block with mould box will be stayed in curing room for 1.5 to 2.5 hours(curing time is different for different material), then move out automaticly.

Hydraulic frequency converson reversal crane: It turns the mould with block in it 90 degress, puts it on frequency conversion block dragging car and does demoulding work.

Horizontal cutting machine: Reversal crane turns the mould 90 degress, demould and puts the whole block and bottom plate onto block dragging car. The block dragging car will take the whole block into cutting machine, and finish horizontal cutting, peeling the whole by two sides, and separating wasted materials.

Vertical cutting machine: Fixed to the ground, driven by planet-Gear Reducer, while doing vertical cutting, the cutting machine does eccentric and swinging cutting which increases cutting effciency, pas rate and makes it more convenient to change cutting size.

Semi-finished spreader: After cutting, semi-product transporting crane carry block to stram car for enter autoclave.

Finished product clamp: Handing the separated block to the packing area, reduce labor intensity and scrap, improve production effciency and yield.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal, Cash