XK6132 Vertical Knee-Type machinery equipment

group nameVertical

-

Min Order1 piece

brand namesino cnc machining center

modelXK6132

payment methodT/T, L/C, D/P D/A

-

update timeSun, 07 Dec 2025 07:29:22 GMT

Paramtents

Brand SINO

Numerical control FANUC/SIEMENS/MITSUBISHI/GSK

Three axes Box guideway

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Product Introduction

XK6132

High Rigidity Vertical Keen-type Milling machine

- 7:24 No.50

SPINDLE HOLE TAPER

- 3

AXIS

- 30-1500

RPM

- 18

SPINDLE SPEED STEPS

XK6132 High Rigidity CNC Vertical Keen-type Milling machine

XK6132 CNC vertical knee-type milling machine is the machineary equipment three axis controlled by CNC system but spindle kept the high rigidity by gear transmission. Mounted with face, cylindrical, side, bevel and formed milling cutters, the machine is suitable to process flat, inclined surface, slots and gears on miscellaneous work pieces. One operator can operate three machines at the same time.

Equipped with optional accessories, such rotary table and dividing head, machine can be applicable to versatile processing. It is an ideal machine tool for machining process, maintenance, instrument, die and moulds.

Product Detailed Parameters

Machine Model : XK6132

| Table | Value | Unit |

|---|---|---|

| working size | 1320 x320 | mm |

| Max. load capacity | 500 | kg |

| Travel | Value | Unit |

|---|---|---|

| longitudinal travel X | 700 | mm |

| cross travel Y | 300 | mm |

| Vertical travel Z | 280 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle hole taper | 7:24 No.50 | |

| Spindle speed | 30-1500 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 4000/3000/2000 | mm/min |

| Moter power | Value | Unit |

|---|---|---|

| Main motor power | 7.5 | Kw |

Product Details Map

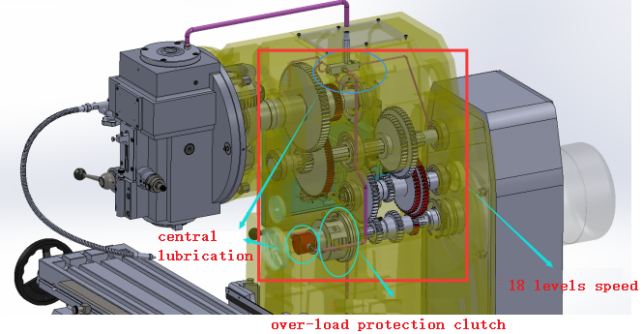

Transmission:

Spindle are in hardened gear transmission with 18 grades speed ranges. It supplies high rigidity process. The Max. torque can reach 2800N.M.

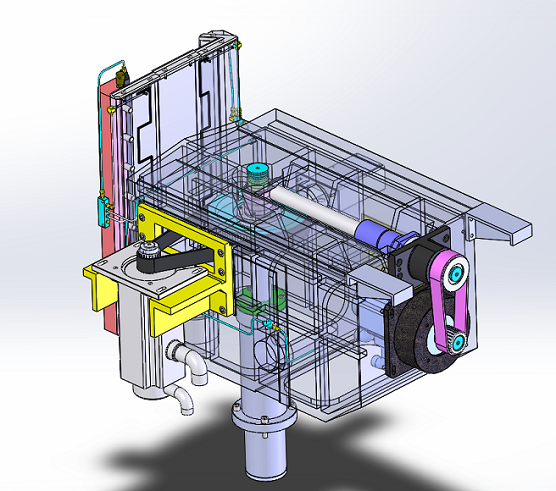

Three axis driven by servo motor and ball screw:

Three aixs are driven by servo motors and ball screws. They are controled by CNC system which can increase the efficiency.

Timing lubrication :

An automatic timing lubrication pump supplies central lubrication to guideways, ball screws to ensure accuracy and machine long life.

-

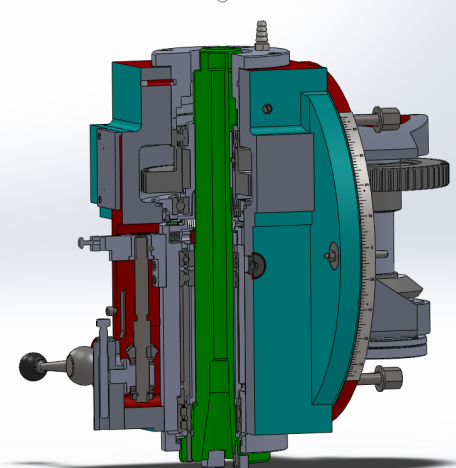

Vertical head :

Vertical head can be rotated by ±45°

The spindle quill can move 75mm

Protection shield is optional :

Due to the environmental issue, more and more customers will choose protection shield for such kind of economical cnc machine.

You need a product

You May Like

- Nearest port for product export

- shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A