Automatic high speed checkweigher

group nameOnline automatic checkweigher

-

Min Order1 piece

brand nameSyndar

modelCW8070L20,CW10070L40,CW12070L60,CW8080L20,CW10080L

payment methodT/T

-

update timeFri, 26 Feb 2021 17:33:19 GMT

Paramtents

Dynamic checkweigher display division 1g;

Checkweigher machine range 0.2-20kg;

Check weighing accuracy ±10-15g;

checkweigher reject system reject device push rod type, sliding type optional;

Online checkweigher checkweighing segment number standard 1 segment, optional 3 segments;

Packging & Delivery

Min Order1 piece

Briefing

Detailed

|

Product number

|

CW8070L20 |

CW10070L40 | CW12070L60 | CW8080L20 | CW10080L40 | CW12080L60 |

|

Display index

|

1g

|

1g | 5g | 1g | 1g | 5g |

|

Checkweighing range

|

0.2-20kg

|

0.5-40kg | 0.5-60kg | 0.2-20kg | 0.5-40kg | 0.5-60kg |

|

Checkweighing accuracy

|

±10-15g

|

±10-20g | ±10-20g | ±10-15g | ±10-20g | ±10-25g |

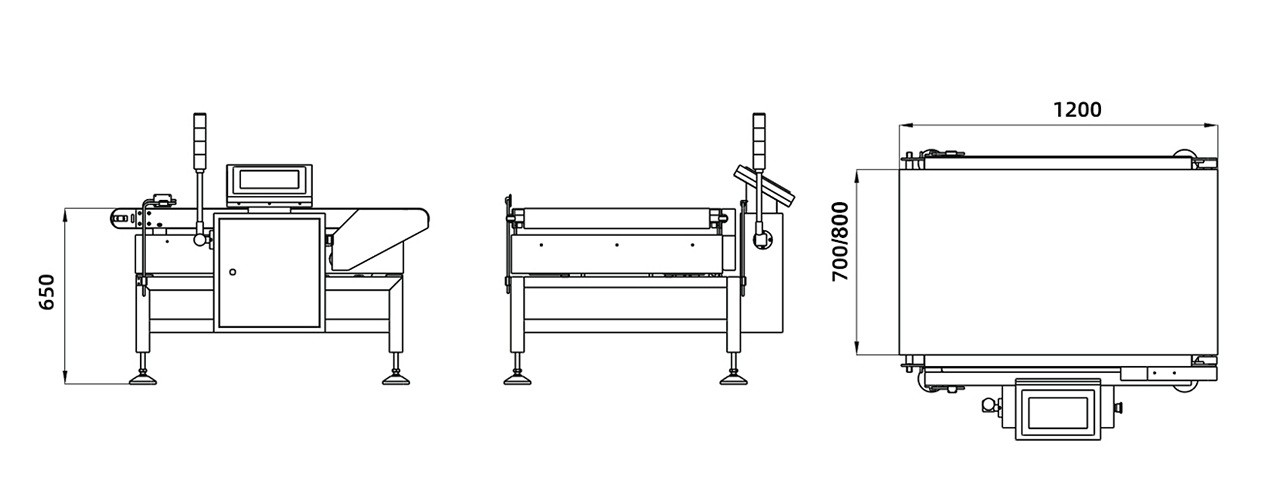

Weighing section size | L 800mm*W700mm | L:1000mm*W 700mm | L 1200mm*W700mm | L 800mm*W800mm | L:1000mm*W 800mm | L 1200mm*W800mm |

Applicable product size | L≤600mm,W≤700mm | L≤800mm,W≤700mm | L≤1000mm,W≤700mm | L≤600mm,W≤800mm | L≤800mm,W≤800mm | L≤1000mm,W≤800mm |

Weighing control system | The checkweigher system uses SYNDAR weighing controller system V1.15 | |||||

Belt speed | 5-80/minute | |||||

Quantity | 20-50 kinds | |||||

Rejection device | Push rod type and slide type are optional. | |||||

Number of checkweighing sections | Standard 1 stage, optional 3 stages; | |||||

Standard technical parameters | Power supply: standard single-phase AC200~240V, 50/60Hz, 0.4KW, optional three-phase AC380V, 50/60Hz, 0.4KW Air source: dry 0.5~0.8MPa (5~8bar) Temperature: Operating temperature: 0℃~40℃, storage temperature: -20℃~60℃ checkweigher scales humidity: 10~90%RH, no condensation Protection level: IP30, IP54, IP65 optional high speed checkweigher noise: ≤75db Machine weight: ≈60kg Working height: 650±50mm (confirm when ordering other heights) | |||||

Material | Load cell: aluminum, alloy steel optional Roller: carbon steel Structure: stainless steel 304, carbon steel optional Conveyor belt: black, PVC wear-resistant belt | |||||

You need a product

You May Like

6YRS GZ Syndar Co., Ltd.

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T