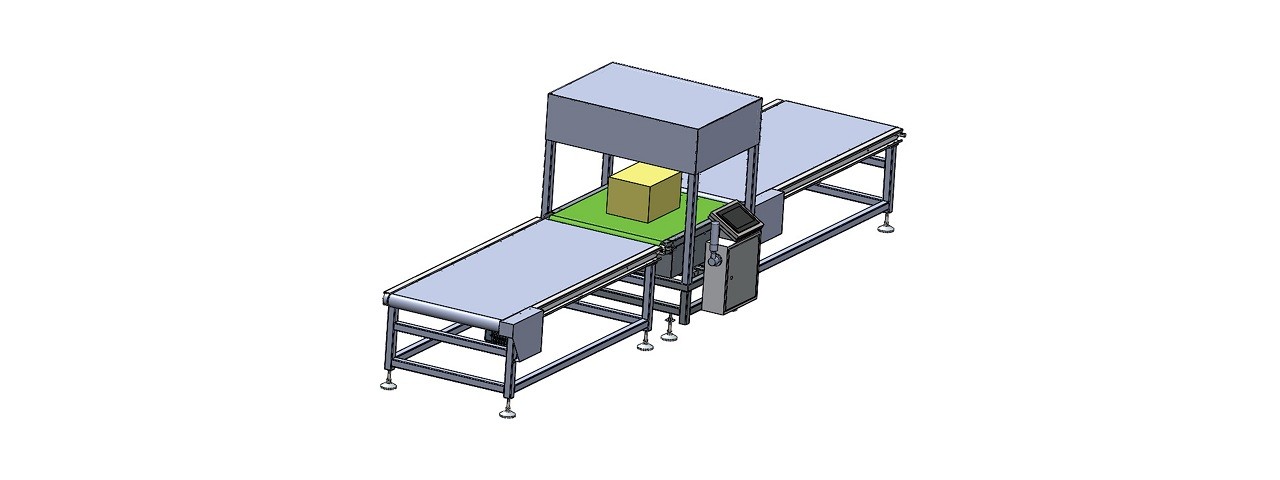

Labeling automatic checkweigher

group nameCustomized combination checkweigher

-

Min Order1 piece

brand nameSyndar

modelCML3530L1,CW3523L1-15,CW4023L2-20

payment methodT/T

-

update timeFri, 23 Oct 2020 11:51:11 GMT

Paramtents

checkweigher scales display graduation 0.1g;

Weighing range 1-1000g;

Checkweigher machine accuracy ±0.5-2g;

Scanning method/scanning angle two-dimensional image type (838*640 pixels)

online checkweigher Volume measurement range 5*5*5 (cm) ~ 60*60*60 (cm)

Packging & Delivery

Min Order1 piece

Briefing

Detailed

|

Product number

|

CML3530L1 | CW3523L1-15 | CW4023L2-20 |

|

Display index

|

0.1g

|

0.1g

|

0.1g

|

|

Weighing range

|

1- 1000g

|

1-1000g

|

2- 5000g

|

|

Weighing accuracy

|

± 0.5- 2g

|

± 0.3-0.6g

|

± 1-5g

|

Weighing section size | L 350mm*W 300mm | Fe:≥0.8mm;SUS:1.6mm | Fe:≥1.5mm;SUS:2.6mm |

Applicable product size | L≤200mm,W≤300mm | L:350mm*W 300mm | L 500mm*W 400mm |

Weighing control system | SYNDAR online weighing, scanning code, printing and labeling, volume measurement control system V1.2.5 | ||

Belt speed | 5-80/minute | ||

Quantity | 20-50 kinds | ||

Scanning method/scanning angle | Two-dimensional image type (838*640 pixels) / horizontal 42°, vertical 33° | ||

Print mode/print resolution | Thermal transfer printing/300-600 dots | ||

Labeling method/labeling direction | Receive command induction type automatic labeling/±1mm (related to product positioning accuracy) | ||

Labeling speed/labeling accuracy | ≤30 sheets/minute (related to label printing specifications and data receiving time)/paper out in the horizontal direction. | ||

Volume measurement range | 5*5*5(cm)~60*60*60(cm) | ||

Volume measurement accuracy | ±0.5cm | ||

Standard technical parameters | Power supply: standard single-phase AC200~240V, 50/60Hz, 0.4KW, optional three-phase AC380V, 50/60Hz, 0.4KW Air source: dry 0.5~0.8MPa (5~8bar) Protection level: IP30, IP54 optional dynamic checkweigher machine weight≈100kg Working height: 650±50mm (confirm when ordering other heights) | ||

Material | checkweigher load cell: stainless steel, aluminum, alloy steel optional Roller: carbon steel Structure: stainless steel 304, carbon steel optional Conveyor belt: black, PVC wear-resistant belt | ||

You need a product

You May Like

6YRS GZ Syndar Co., Ltd.

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T