China Automatic 2ply Corrugated Cardboard Production Line

group name2ply Corrugated Cardboard Production Line

-

Min Order1 piece

brand nameJumbo Corrugated Machinery Solution

modelWJ100-1400

payment methodPayPal, Westem Union

-

update timeSat, 09 Oct 2021 08:20:51 GMT

Paramtents

Maximum paper width 1400mm

Working speed 100m/min

Corrugation Type 2Ply

Crosscutting precision ±1.5mm

Total Power 50kw

Cutting length 300-9000mm

Automatic Grade Automatic

Packging & Delivery

Min Order1 piece

Briefing

Detailed

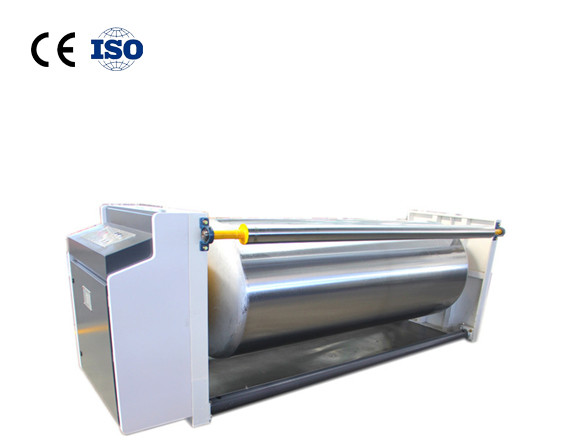

Wj100-1800 - Single side corrugated board production line

Corrugated board production line

A B C D E

Ridge type50kw

Total powerSteam heating

Heating modeLeft or right

Paper output direction

Configuration instructions for single machine

Hebei hengchuangli Carton Machinery Co., Ltd. is located in the south of Beijing and the north of Jinan. The water and land transportation is very convenient. It is a professional enterprise producing carton machinery and printing machinery on a considerable scale. The company has complete mechanical equipment, high degree of specialization, rich manufacturing experience, strong technical strength, advanced testing means and complete management system. It is a rising star in China's carton printing machinery industry.

The company has more than 30 years of R & D and manufacturing experience. The company has been adhering to the service concept of "quality as the guarantee, service as the purpose and customer first", and engaged in the R & D and manufacturing of corrugated board production equipment with advanced technology, professional knowledge and computerized management. Based on the present and looking to the future, facing the urgent need to change the current carton machinery, we will actively cooperate with more enthusiasm, strengthen management inside, expand the market outside, strengthen scientific research, develop new product types, improve various performance indicators of existing products, and strive to truly make you 100 assured and 1000 satisfied with Wumart Jiakang products and complete and thoughtful after-sales service, Truly realize our win-win!

Our products have many mechanical models and complete specifications, which can meet the requirements of different users. In the spirit of "excellence" and "taking the lead", our company actively promotes comprehensive quality management. The products produced have been highly praised by users all over the world for their beautiful appearance, rigorous and meticulous technology, reasonable price and perfect after-sales service.

- If the above is not suitable for you, please tell us your needs and we will reply to you at the first time.

- contact us

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union