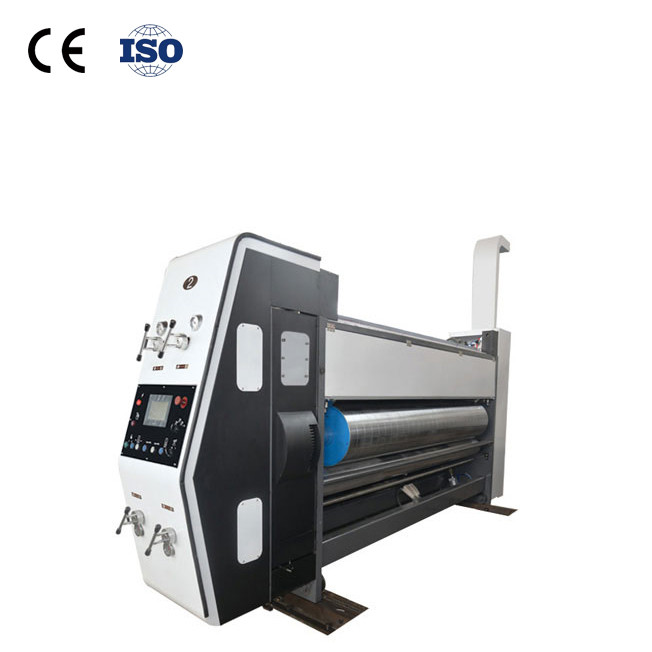

Automatic Flexo Printing Slotting Die-cutting Machine for Corrugated Carton Box Making

group namePrinting machinery

-

Min Order1 piece

brand nameJumbo Corrugated Machinery Solution

model1224

payment methodPayPal, Westem Union

-

update timeSat, 09 Oct 2021 08:23:56 GMT

Paramtents

Maximum feed size (mm) 120x2500

Minimum feed size (mm) 350x600

Maximum speed (piece/min) 150

Paper feeding precision (mm) ±1.0

Thickness of standard printing plate (mm) 7.2mm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Automatic Flexo Printing Slotting Die-cutting Mach

Technological parameter:

Project/Type | ZYKM-B1022 | ZYKM-B1224 | ZYKM-B1228 | ZYKM-B1424 | ZYKM-B1428 | ZYKM-B1624 | ZYKM-B1628 | ZYKM-B1632 | |

|---|---|---|---|---|---|---|---|---|---|

Maximum speed (piece/min) | 150 | 150 | 140 | 150 | 140 | 120 | 120 | 100 | |

Paper feeding precision (mm) | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | |

Maximum feed size (mm) | 1000x2300 | 120x2500 | 1200x2900 | 1400x2500 | 1400x2900 | 1600x2500 | 1600x2900 | 1600x3300 | |

Minimum feed size (mm) | 300x600 | 350x600 | 350x600 | 400x600 | 400x600 | 450x600 | 450x600 | 450x600 | |

Size of drawing paper (mm) | 1300x2100 | 1500x2500 | 1500x2900 | 1700x2500 | 1700x2900 | 2000x2500 | 2000x2900 | 2000x3300 | |

Maximum printing area (mm) | 1000x2200 | 1200x2400 | 1200x2800 | 1400x2400 | 1400x2800 | 1600x2400 | 1600x2800 | 1600x3200 | |

Printing set (mm) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | |

Thickness of standard printing plate (mm) | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | 7.2mm | |

Minimum slotting interval (mm) | Positive knife | 160x160 | 160x160 | 160x160 | 160x160 | 160x160 | 160x160 | 160x160 | 180x180 |

Scalpel | 270x65 | 270x65 | 270x65 | 270x65 | 270x65 | 270x65 | 270x65 | 290x70 | |

Maximum groove depth (mm) | 250 | 300 | 300 | 350 | 350 | 400 | 400 | 400 | |

Slotting accuracy (mm) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | |

Die cutting precision (mm) | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | ±1.0 | |

Paper feeding unit:

· Roller leading edge paper feeding system, independent electronic shaft, extended paper feeding. Adopting international advanced technology, the system is stable and the paper feeding precision is high.

· The suction fan assists in feeding paper, and the air volume is adjusted by frequency to ensure the smooth feeding of the curved cardboard. Suitable for 3, 5, 7 pressed corrugated board.

· The front bezel is manually adjusted and the dial is displayed for direct convenience.

· The left and right side flaps are individually adjusted and displayed digitally.

· The tailgate is electrically adjusted, which is simple and convenient.

· Double conveyor roller mechanism, the first group of paper feed rollers adopts floating structure, and the pressure can be adjusted by spring force. Manual adjustment of clearance, signage, The adjustment range is 1 to 12 mm.

· A brush at the entrance of the paper feed roller to remove impurities from the cardboard surface. A dust mechanism is installed between the two sets of paper feed rollers for sucking away impurities on the surface of the cardboard.

To improve the quality of printing.

Printing unit:

· Printing roller: steel cylinder, surface grinding, hard chrome plating. Diligent balance correction, the link is stable.

· The axial adjustment is manually adjusted, and the axial adjustment range is 10mm.

· Ratchet fixed roll shaft. The full version of the grooved loading and unloading printing plate, the foot switch electric control is reversed.

· The gap of the presser roller is manually adjusted, and the label is displayed. The adjustment range is 4~12mm.

· Rubber roller printing system. The surface of the steel pipe is covered with wear-resistant rubber, and the medium and high special grinding. The gap is electrically adjusted, digital display, and the adjustment range is 0 to 6 mm. (selected With: scraper ink system)

· Grinding anilox rolls: with a separate motor-driven idler to ensure ink is not known during shutdown. Network cable: 160 to 500 optional. (Optional: Ceramic Anilox roller)

· The paper feed ring can be quickly moved and locked. (Optional: Full vacuum Fu-delivery system)

Slotting unit:

· Pre-pressure wheel device: electric linkage type slotting, pressing line and pre-pressing are completed once.

· Electric adjustment of the length, width, height and folding of the carton, digital display.

· The pressure of the pressure roller is manually adjusted, and the dial displays the adjustment value.

· Slotting knife thickness 7mm, alloy steel material, zigzag heat treatment toothed grinding, sharp edge, high precision.

· The slotted phase is adjusted by computer electric numerical 360 degree.

· Add a hand hole holder.

· Install a chain control switch in the slotted section to achieve emergency stop, stop or resume paper feed.

Die cutting unit:

· Manually adjust the die cutting pressure gap.

· The pad roller automatically traverses the swimming device.

· Imported quick-change rubber pad and wear resistance.

· Speed difference compensation system ensures line speed consistency and guarantees accuracy.

· Pad grinding mechanism to extend the life of the pad and reduce consumption.

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union