Fully Automatic 3 ply corrugated board production line Carton machinery high speed corrugated board produ

group name3 ply layer corrugated board production line

-

Min Order1 piece

brand nameJumbo Corrugated Machinery Solution

modelType 1800

payment methodPayPal, Westem Union

-

update timeSat, 09 Oct 2021 15:26:34 GMT

Paramtents

Ridge type A, B, C, D, e, f

Function of corrugated board production line Corrugated board production line is made of web ba

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Carton machinery high speed corrugated board produ

The hydraulic support adopts full hydraulic drive to complete the actions of base paper clamping, loosening, moving centering, left and right translation, and the base paper lifting adopts hydraulic drive. Spindle ¢ 240mm, hyperbolic heavy rocker arm, toothed paper clamping head, multi-point brake, hydraulically driven lifting, left-right translation, medium alignment. The guide rail is 6000mm long and welded with medium plate.

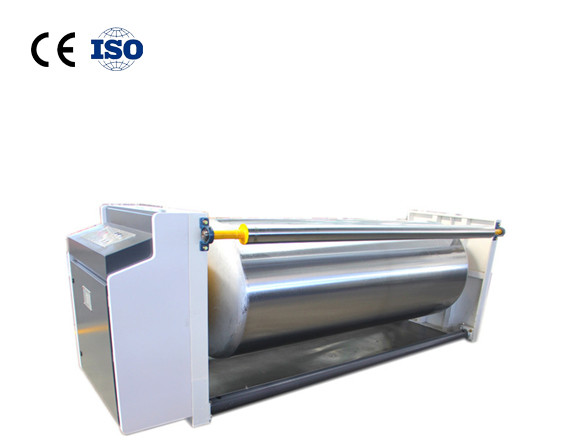

The drawer type single-sided machine is sprayed with tungsten carbide, the tile roller is quickly replaced by the electric trailer in 10 minutes, the synchronous belt with high efficiency and energy saving rotates, the maintenance free air bag is used for pressurization, the independent gluing unit, PLC automatic glue control, man-machine interface touch screen display, automatic shutdown and pressure relief when the paper is broken, the main ridge roller: ¢ 360mm (different according to the ridge type), the pressure roller ¢ 415mm, Preheating roller ¢ 400mm. The negative pressure design is adopted with low heat loss, so that the core paper can be evenly pressed and attached to the surface of the corrugating roller, so as to better shape the corrugating. Because of the uniform pressure, the top of the corrugating can be better and evenly coated with glue, so that the bonding condition of single-sided corrugating paper is better.

The main beam of the conveying bridge adopts 200mm channel steel, and the paper hauling conveying is driven by an independent frequency conversion motor. Both sides are equipped with safety guardrails, ladders (made of No. 8 small channel steel) and high-strength herringbone pedals to ensure personnel's work safety and convenient operation. The surfaces of paper pulling shaft, tension shaft and paper feeding shaft are ground and plated with hard chromium. Vacuum adsorption tension control, 5-inch air suction pipe, plus regulating valve, the air volume can be stepless and adjustable. In front of the deviation correction baffle, double guide columns are used for positioning and lead screw drive, so that the positioning is fast and accurate and the walking is stable.

The diameter of the roller of the gluing machine is 269mm. Each floor is driven by an independent variable frequency motor, and PLC adjusts the gluing gap and man-machine interface. After the surface of the rubber coating roller is quenched and tempered, the inner hole is processed, the dynamic balance surface is finely ground and engraved with 32 line pit anilox, the glue coating is uniform and the glue consumption is less. Glue quantity digital display is adjusted electrically for glue application. Automatic circulating glue supply can effectively control the glue amount, avoid glue precipitation, ensure good glue and save glue. All roller shaft surfaces are hard chrome plated after grinding. Electrical design, production and construction process follow national standards and specifications, with low failure rate and simple maintenance.

The frame of the double-sided machine is 360 mm national standard channel steel, with 600 mm * 12 chrome plated hot plates. The inlet adopts arc hot plates to raise the temperature of the face paper at an extremely high speed, and the whole process touch plate design structure. PLC automatically controls the pressing plate. Upper and lower belt automatic deviation correction, temperature display, variable frequency motor. The surface of the heating plate is ground. The width of the heating plate is 600mm. There are 12 heating plates in total, and the length of cooling shaping is 4m. The heating plate is made of container plate, which meets the national class I pressure vessel standard, and is attached with pressure vessel certificate and inspection certificate. The left and right deviation correction adjustment of the upper conveyor belt adopts pneumatic automatic deviation correction. The heat conduction piping of the heating plate is divided into four sections to control the temperature, and a temperature display is set.

The thin knife indentation machine adopts tungsten alloy blade, six knife ten wire type and zero line pressing type. The full servo computer automatically arranges knives, and the width of the suction outlet is automatically adjusted. Synchronous servo motor controls tool arrangement and wire arrangement. Automatic reset. Precise size. The order replacement time is 3-8 seconds. Two machines can be used together to change orders immediately without reducing speed. Store 999 groups of orders to realize automatic order replacement or manual order replacement without shutdown. Schneider m258 PLC control system adopts CANopen bus system, has order management function, and is equipped with signal input interface synchronized with dryer speed. Three crimping forms: convex to concave (three-layer line), convex to concave (five-layer line) and convex to flat. The three crimping forms can be electrically converted. The depth of the crimping wheel can be automatically controlled by computer. It has good linearity and is easy to bend.

The spiral cutter cross cutting machine adopts full AC servo control, energy storage braking, spiral cutter structure, oil immersed gear transmission and 10.4-inch touch screen display. It can store 200 groups of orders, change paper cutting specifications quickly and accurately, change orders without stopping, and realize computer networking to facilitate production management. The cutter shaft transmission gear is made of precision forged steel by high-frequency quenching to realize backlash free transmission. It adopts advanced keyless connection mode with high transmission accuracy. The blade of the cross cutting machine adopts the structure of steel inlaid spiral knife and sawtooth knife type. Scissors shear, small shear force, long blade life.The front and rear paper feeding wheels adopt the paper pressing mode of sun wheel, with stable transportation and uniform pressure, which is not easy to crush the plate or cause blockage. Precision adjustable gapless gear ensures accurate meshing of knife edge and balanced operation. Independent oil pump and filter are used together with two groups of red copper tubes distributed at each gear position for oil supply, lubrication and cooling. Knife roller: made of high-quality precision forged steel, after balance treatment, it has good stability.

Gantry stacking. The order change time is 5 seconds, which can be counted automatically, cross out automatically and change orders automatically. Synchronize with the production management system, order management, centralized management, automatic order replacement without speed reduction. Crawler stacking platform, AC servo control lifting, stable and neat stacking; When the stacking reaches the set quantity, the frequency conversion control automatically and stably outputs the paper horizontally; AC servo control positioning of rear baffle, automatic, fast and accurate adjustment when changing orders; The rear baffle can shift automatically, which is suitable for stacking small orders; Fully automatic operation control, improve efficiency, save manpower and reduce the labor intensity of operators;

The glue making device is composed of carrier tank, main tank, storage tank, glue delivery pump and glue return pump. The horizontal glue making machine can prepare the main glue and carrier glue at the same time, mix and stir, and the glue making amount is large. The glue liquid in the storage barrel of the glue making room is transported to the storage barrel of each glue equipment by the glue pump to provide glue liquid for the equipment. The storage barrel and glue supply barrel are equipped with mixing device to avoid the precipitation and agglomeration of glue liquid. The glue making device is composed of carrier tank, main tank, storage tank, glue delivery pump, glue return pump, etc. The glue making system adopts circulating glue supply, the remaining glue flows into the glue return square barrel, and the liquid level floating ball is automatically controlled. The glue liquid in the glue return square barrel is pumped back to the storage barrel of the glue equipment for circulating glue supply, so as to save the glue liquid and prevent the glue liquid from gelatinization, caking and precipitation in the glue tray.

You need a product

Related Searches

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union