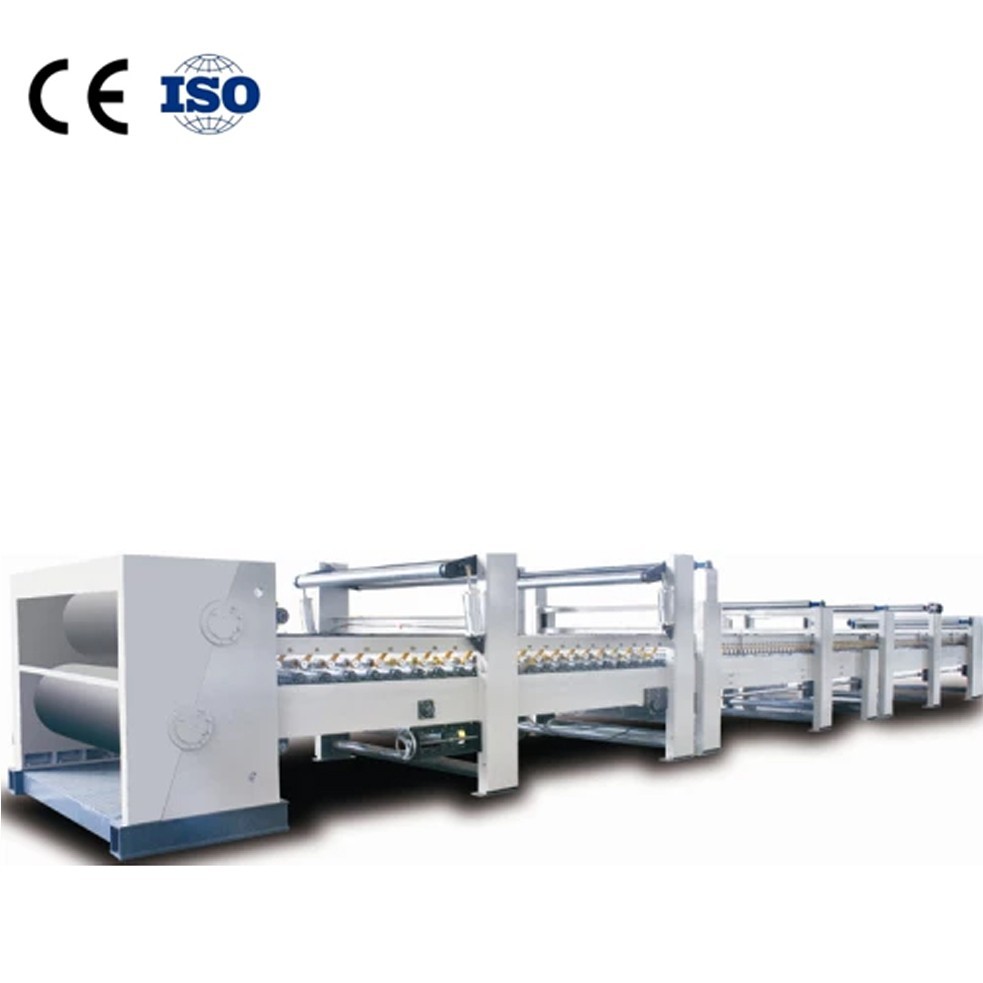

Application of heating compound machine in corrugated board production line

group nameCorrugating Machine Double Facer

-

Min Order1 piece

brand nameJumbo Corrugated Machinery Solution

modelSM-10

payment methodPayPal, Westem Union

-

update timeSat, 09 Oct 2021 09:03:50 GMT

Paramtents

Cooling stereotypes length 4m

Temperature requirement 160—200℃

Steam pressure 0.8-1.3MPa

Air source pressure 0.6—0.9MPa

Upper drive rubber roller diameter ¢700mm

Lower drive rubber roller diameter ¢400mm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Double Facer Corrugated Box Making Machine

The surface of the heating plate is grinded, the width of the hot plate is 600mm, there are 12 heating plates, the cooling setting is 4 meters.The heating plate is made of vessel plate, which conforms to the national first-class pressure vessel standard, with pressure vessel certificate and inspection certificate.

The upper conveyer belt rectifies the right and left side to adopt the pneumatic automatic correction deviation.

Heating plate heat transfer pipe temperature control sub-four-segment, with a temperature display.

Double cylinder S type cotton belt tensioning device is used for upper cotton belt.

The lower belt adopts pneumatic tension, pneumatic correction.

Drive roller coated with attached wear-resistant rubber

,

showed a herringbone structure

,

With a high, ensure smooth cardboard output

。

Main drive motor for frequency conversion motor

,

low-speed torque

,

wide speed range ,reliable, and easy maintenance.

Hot plate internal for partition isolation structure,s-shaped flow of steam

,

Steam, water separation function significantly improves the utilization of steam

。Design speed: 150-180m / min, width: 1400m-2000m, heating plate mechanism: 600mm, the number can be configured as 8-14 according to the production line speed, sectional cross steam supply, the surface of hot section plate is ground and plated with hard chromium, which meets the national standard of class II pressure vessel. The hot section adopts pressure roller structure, and sectional pneumatic pressure adjustment can be selected according to the number of cardboard layers, The air cylinder tensioning device is adopted for the cotton belt, and the electric or automatic conveyor belt deviation correction device is selected. The driving part adopts oil immersed gearbox, which can be driven by electromagnetic speed regulation electric or frequency conversion motor,The surface of the main drive roller is wear-resistant rubber, and the surface is in waist drum shape to prevent deviation of the conveying belt.

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union