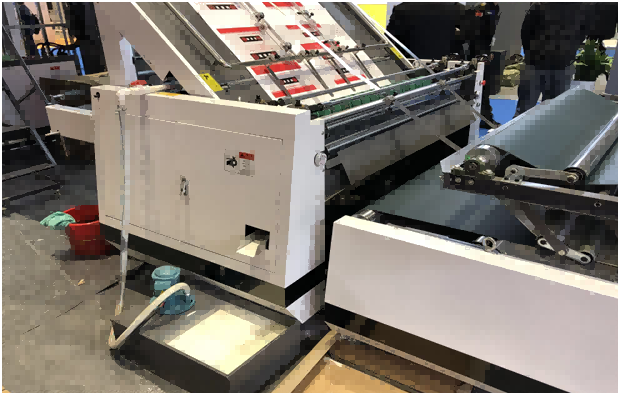

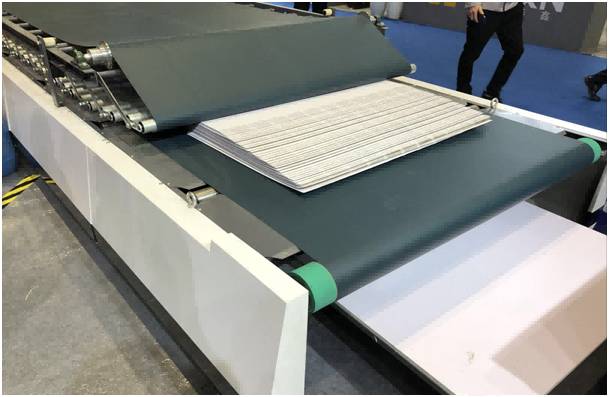

1300A/1600A Front gauge automatic paper mounting machine Front gauge automatic paper laminating machine

group nameFully automatic flute laminating machine

-

Min Order1 piece

brand nameJumbo Corrugated Machinery Solution

model1600

payment methodPayPal, Westem Union

-

update timeSat, 09 Oct 2021 15:48:43 GMT

Paramtents

Max size of cover face 1600X1250mm

Mix size of cover face 400mmX400mm

Top paper thickness 140-800g

Bottom sheet thickness 2/4 ply A/B/C/E/F Flute

Economic speed 0-8000pcs/h

Precision ±1mm

Power 14kw

Size 13.5m x 2.3m x 2.9m

Weight About 5.5T

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Reply your inquiry in 24 working hours.(our normal working time:6:00~22:00)

Experienced staffs answer all your questions in time.

Customized design is available.

Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

Special discount and protection of sales are provided to our distributor.

Professional factory: We are manufacturer, specializing in producing all kinds of CNC MACHINING CENTER.

As an honest seller, we always use superior raw material, advanced processing/testing machines, skilled technicians to ensure our products to be finished in hight quality and stable feature.

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union