Computer control thin blade cutting and creasing machine NC-200N thin blade slitter scorer machine

group nameNC Cut Off Machine

-

Min Order1 piece

brand nameJumbo Corrugated Machinery Solution

modelOrdinary CNC cutting machine

payment methodPayPal, Westem Union

-

update timeSat, 09 Oct 2021 15:53:57 GMT

Paramtents

color white

The machine warranty A year

width Can be customized

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Maximum slitting board width: 2700mm | Minimum crimping width: 150mm | Pneumatic pressure: 0.6-0.8mpa |

Maximum mechanical speed: 200/min | Minimum feed length: 220mm | Order storage: 999 |

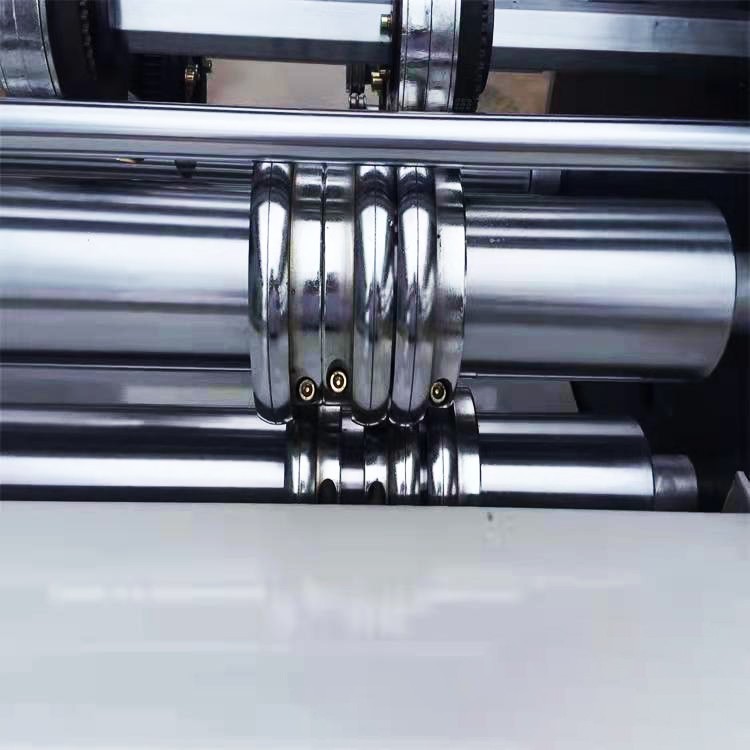

Number of separation knives: 5 tablets | Outer diameter of paper separation thin blade: 230mm | Diameter of crimping wheel: 156mm |

Number of crimping wheels: 8 pairs | Thickness of paper separation thin blade: 1.3mm (alloy) | Machine weight: 3500kg |

Minimum slitting width: 180mm | Motor power: 5.5kW speed regulation | Overall dimensions of the machine: 4200*1250*2100mm |

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union