CE industrial beam safety barrier curtain beam safety grating for conveyor belt

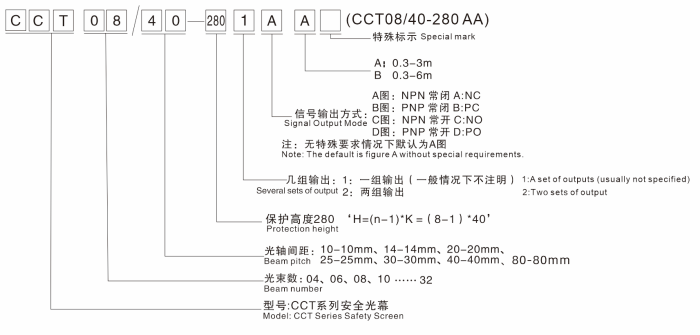

group nameCCT universal safety light curtain sensor

-

Min Order1 piece

brand nameCYNDAR

modelCCT

payment methodT/T, PayPal

-

update timeSun, 21 Feb 2021 21:42:08 GMT

Paramtents

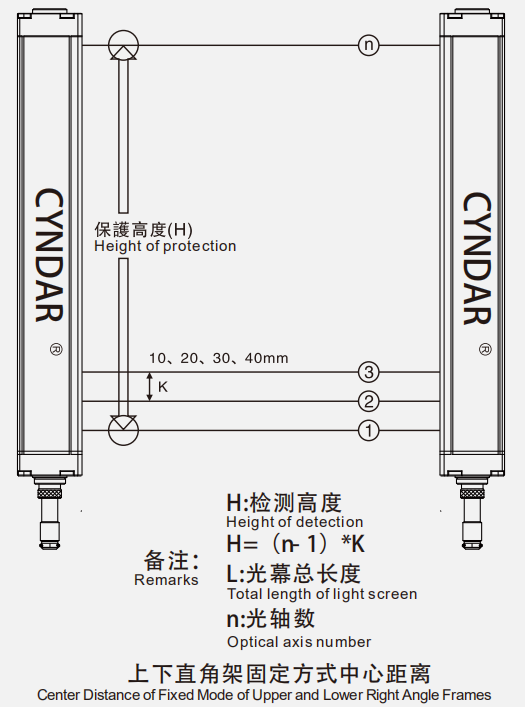

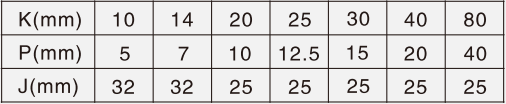

Optical axis spacing 10-40MM

Detection accuracy 18-48MM

Response time ≤15ms

Packging & Delivery

Min Order1 piece

Briefing

Detailed

CE industrial beam safety barrier curtain beam safety grating for conveyor belt safety light curtain is a safety-certified light curtain product, which consists of two parts. The emitter emits modulated infrared light and is received by the receiver to form a protective net. When an object enters the protective net, when light is blocked by the object, through the internal control circuit, the receiver circuit immediately responds.

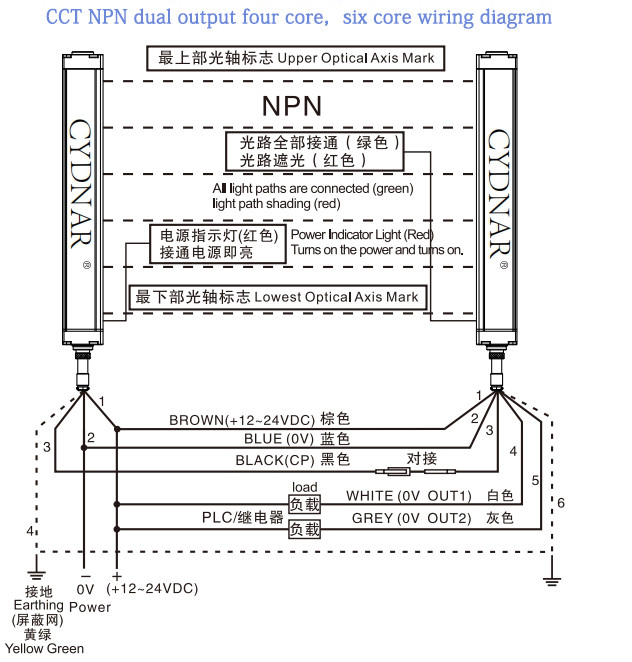

Signal cable: used to transmit the signal between the controller and the transmitter and receiver.

Control cable: used to connect the controller and the machine tool and equipment to realize the safety control of the machine tool or other equipment.

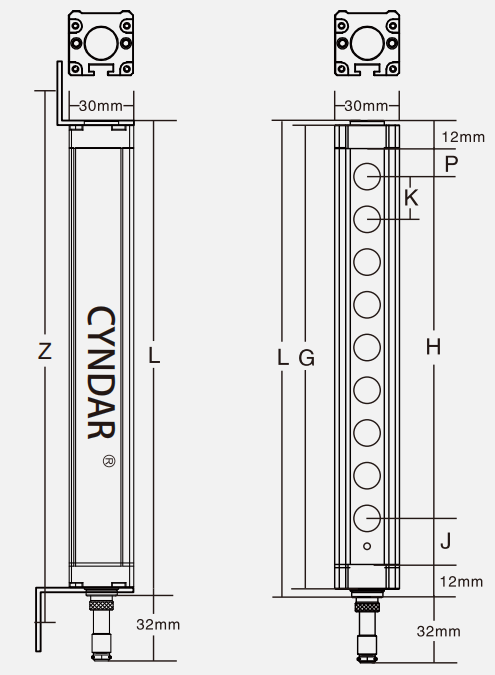

Mounting bracket: Fix the transmitter and receiver on the machine.

How to align the safety light curtain sensor?

1. The safety light curtain illuminator and the light receiver are allowed to have a certain deviation, as long as they are roughly aligned.

2. The indicator light turns green after the light is passed (that is, it is aligned), and the light is blocked (that is, it is not aligned or an object is blocking the infrared light) when the indicator light shows red.

3. Two relay outputs are output as the controller signal output.

You need a product

You May Like

6YRS GZ Cyndar Co., Ltd

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T, PayPal