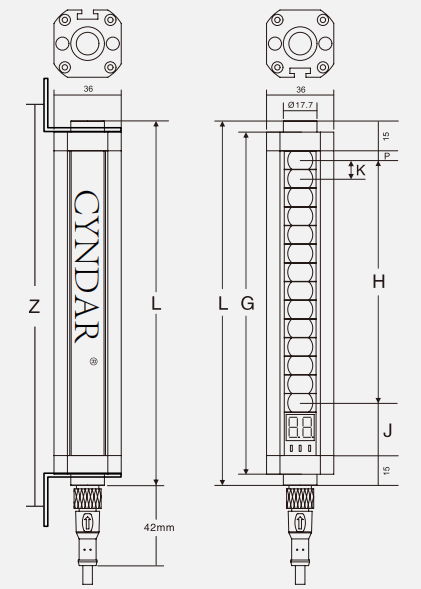

Counting safety light curtain sensor ir light curtain

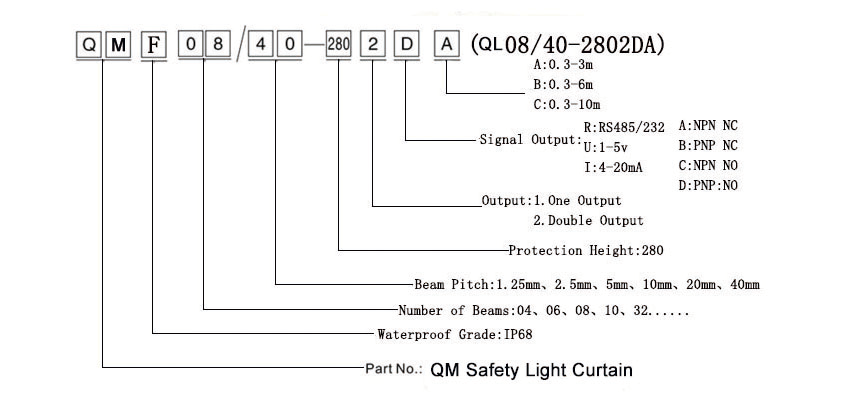

group nameCMT data detection/metering safety light curtain sensor

-

Min Order1 piece

brand nameCYNDAR

modelCMT

payment methodT/T, PayPal

-

update timeSun, 21 Feb 2021 21:36:10 GMT

Paramtents

Reaction time ≤15ms

Protection level IP65

voltage DC 24V

Packging & Delivery

Min Order1 piece

Briefing

Detailed

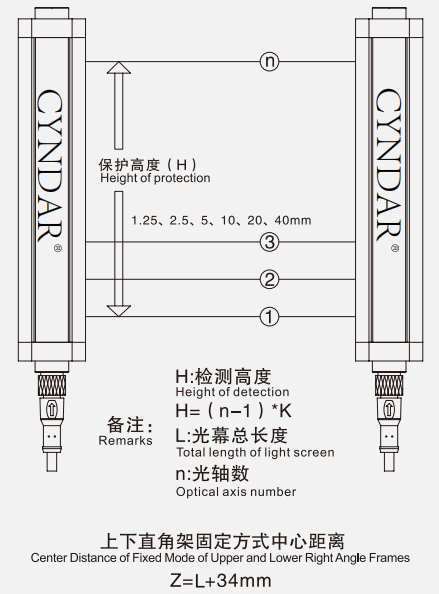

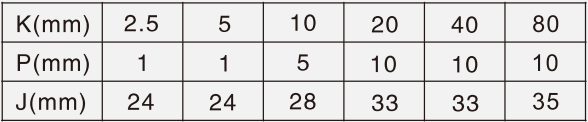

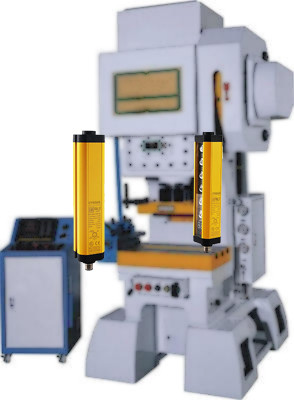

Metering light curtain is an advanced detection method through non-contact measurement. The illuminator emits a beam of light, and the receiver receives it to form a light curtain. By scanning, with the safety light curtain controller and software, it can realize the functions and functions of detection and measurement. application.

The measurement of products is already a very common and necessary task. If you do this work manually, it is not only inefficient but also prone to errors.

1. After changing the mold, the safety distance and position of the protection device must be adjusted by a special manager.

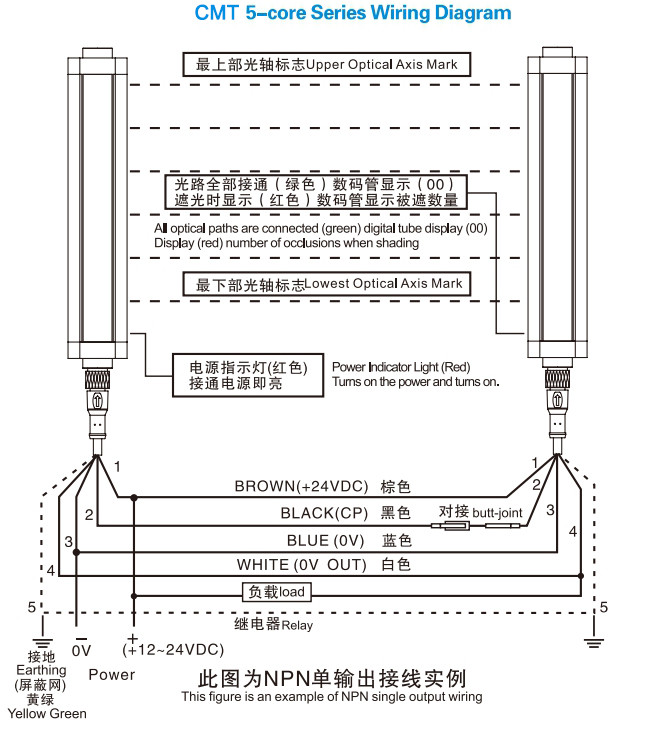

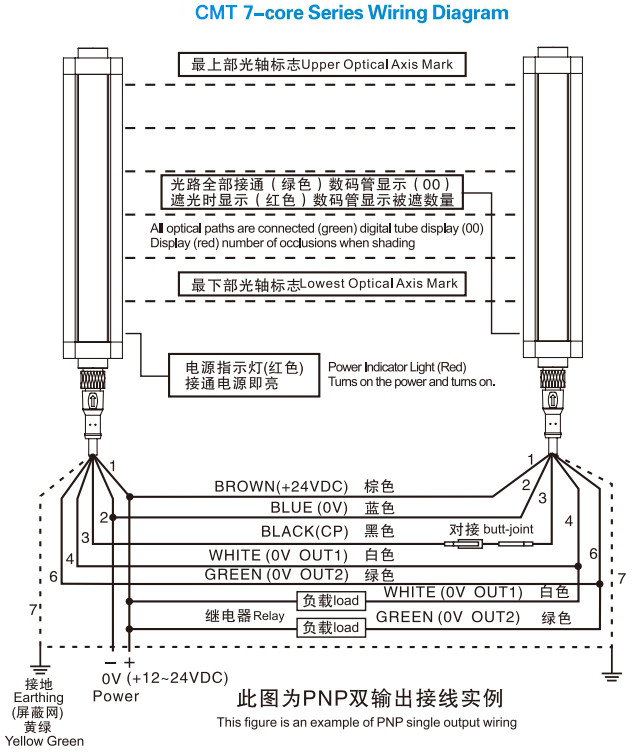

2. When disassembling and assembling the light curtain and the transmission line, the power should be turned off first, and the operation must be performed by professionals to avoid danger.

3. Check whether the transmitter and receiver of the safety light barrier of the safety light barrier are accurately assembled with their respective cables, and whether the terminals of the cables are accurately connected to the power supply and the controller.

4. The safety light curtain sensor is powered on, and the light curtain sensor starts to self-check, synchronize and self-calibrate. After about 1 second, if the yellow indicator light of the transmitter is stable and all the indicators of the receiver are off, it means the light curtain sensor enters. Normal working condition.

You need a product

You May Like

6YRS GZ Cyndar Co., Ltd

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T, PayPal