Hydraulic injection molding machine ir light curtain safety light curtain sensor

group nameCST stamping safety protection safety light curtain sensor

-

Min Order1 piece

brand nameCYNDAR

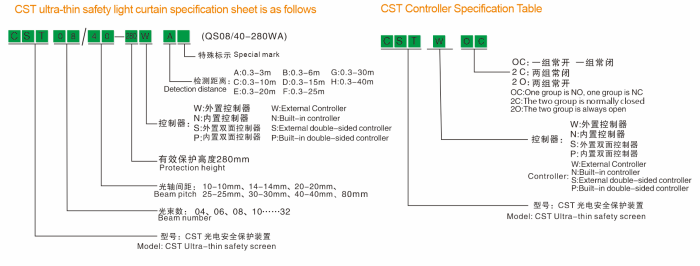

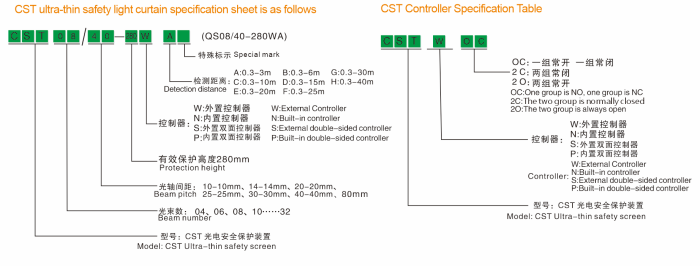

modelCST

payment methodT/T, PayPal

-

update timeSun, 21 Feb 2021 16:29:35 GMT

Paramtents

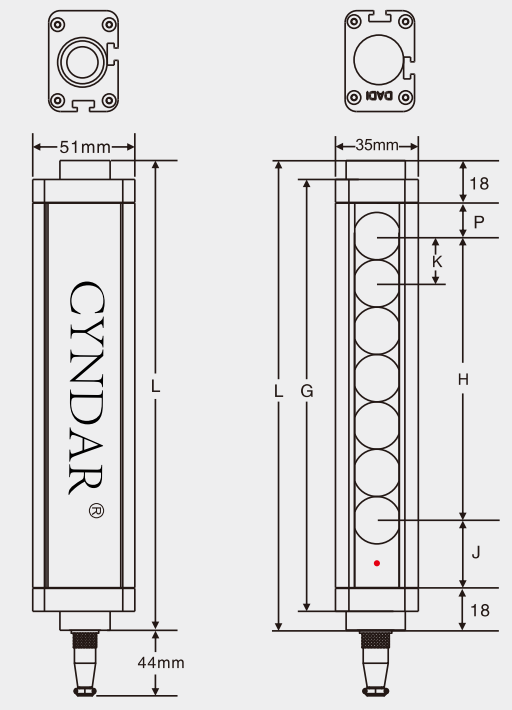

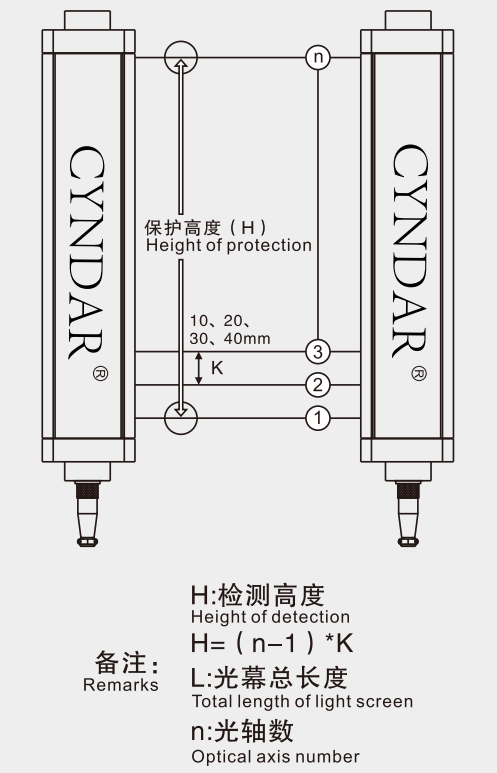

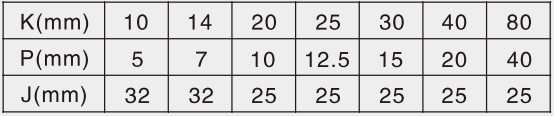

Detection accuracy 18-48mm

Optical axis spacing 10-40mm

light source Modulated infrared LED

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Basic characteristics of safety light curtain sensor

From the role of the light curtain safety device itself, it is known that it is the part that directly contacts the measured object and the window for information input. The basic characteristics of the light curtain sensor refer to the characteristics of the relationship between the sensor’s output and input, which are generally divided into The static characteristics and the static characteristics of the dynamic sensor refer to the static input signal between the output and the input of the infrared curtain sensor.

Operation method of safety light curtain:

1. Check whether the optical curtain is firmly fixed on the equipment to be equipped, whether the transmitter and receiver of the light curtain sensor are in the same plane, and the protection area bordered by the transmitter and receiver should be one of the planes rectangle;

2, check whether the transmitter and receiver of the light curtain safety barrier are correctly assembled with their respective cables, and whether the cable terminals are accurately and firmly connected to the power supply and control unit;

3. Power on the safety curtain sensor. At this time, the light curtain sensor starts self-checking, synchronization and self-calibration. After about 1 second, the transmitter indicator is stable and the receiver indicator lights are all off, indicating that the light curtain sensor enters the normal working state. .

You need a product

You May Like

6YRS GZ Cyndar Co., Ltd

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T, PayPal