Installation of safety relays on production line equipment to protect operators

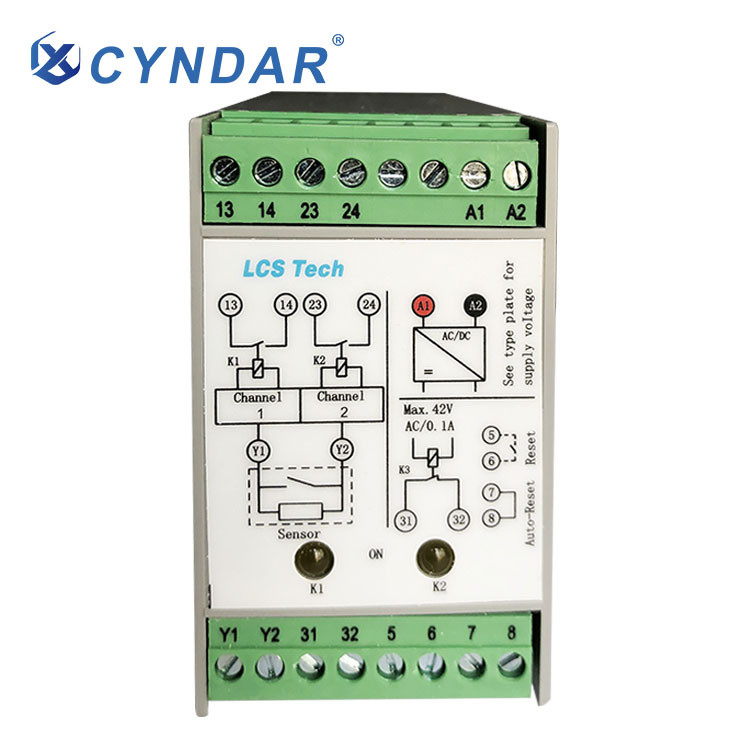

group nameSafety relay for controlling safety sensor

-

Min Order1 piece

brand nameCYNDAR

modelLCS

payment methodT/T, PayPal

-

update timeMon, 08 Feb 2021 17:04:17 GMT

Paramtents

MTTFd >30 years

Protection level IP20

Nop (accepted) 52560/year

Packging & Delivery

Min Order1 piece

Briefing

Detailed

The influence of current ratio on relay reliability: The so-called current ratio is the ratio of the working load current of the relay to the rated load current. The current ratio has a great influence on the reliability of safety control relays, especially when the current ratio is greater than 0.1, the mean time between failures drops rapidly, and when the current ratio is less than 0.1, the mean time between failures is basically unchanged, so it should be used in circuit design The load with a larger rated current can reduce the current ratio, so that the reliability of the relay and even the entire circuit will not be reduced due to the fluctuation of the operating current.

Precautions:

1) In order to maintain the performance of safety control relays, please be careful not to drop safety control relays or subject them to strong impacts. It is recommended not to use the relays that have fallen.

2) Use safety control relays as much as possible in an environment with room temperature and humidity, with little dust and harmful gases. Harmful gases include gases containing sulfur, silicon, and oxidation.

3) For magnetic latching relays, they should be placed in action or reset as needed before use. Pay attention to the polarity and pulse width when applying voltage to the coil.

You need a product

You May Like

6YRS GZ Cyndar Co., Ltd

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T, PayPal