ZCD Combined Type Low Dew Point Dryer | Combined Dryer | Compressed Air Purification System

group nameCombined Dryer

-

Min Order1 piece

brand nameZHENGDA PSA Air Separation Plants

modelZCD

payment methodL/C, T/T

-

update timeThu, 12 Aug 2021 12:02:24 GMT

Paramtents

Air Processing Capacity 1〜300Nm³/min

Operating Pressure 0.6〜1.0MPa

Air Inlet Temperature Normal-temperature Type: ≤45°C (Min 5°C)

Dew Point of the Finished Product Gas -40°C〜-70°C

Switching Time 120min (adjustable)

Pressure Drop Between Air Inlet and Outlet ≤0.03MPa

Gas Consumption for Regeneration ≤6% rated processing capacity

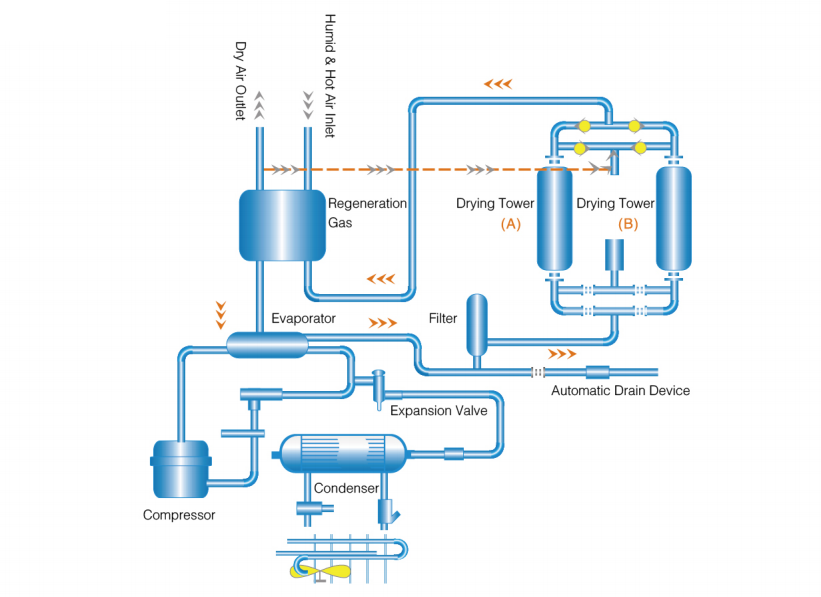

Regeneration Mode Micro-heat regeneration/no-heat regeneration/other

Power Supply AC 380V/3P/50Hz, AC 220V/1P/50HZ

Environmental Temperature ≤42°C

Cooling Type Wind cooling / water cooling

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

6YRS Zhejiang Zhengda Air Separation Equipment Co., Ltd.

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash