Energy saving and environmental protection VPSA Oxygen Generation Equipment|VPSA Oxygen Generators

group nameVPSA Oxygen Generator

-

Min Order1 piece

brand nameZHENGDA PSA Air Separation Plants

modelVPSA

payment methodL/C, T/T

-

update timeFri, 15 Apr 2022 09:28:42 GMT

Paramtents

Product Scale ≥500Nm3/h

Oxygen Purity ≥70〜98%

Oxygen Pressure ≤20MPa (able to be pressurized)

Annual Operation Rate ≥95%

Packging & Delivery

Min Order1 piece

Briefing

Detailed

|

Deep-cooling Air Separation Oxygen Generation Equipment

|

VPSA Oxygen Generation Equipment

|

|

|

Separation Principle

|

Liquefy the air and carry out the separation according to the boiling point difference between oxygen and nitrogen

|

Pressurization & adsorption and vacuumizing & desorption utilize the adsorption capacity deference between oxygen and nitrogen to achieve the separation.

|

|

Process Features

|

The process is complicated. It is required to undergo the compression, cooling/refrigeration, pretreatment, expansion, liquefaction, fractionation, etc., and the operating temperature is less than -180.

|

The process is very simple, and it only needs compression and vacuumizing to achieve the separation; the operating temperature is the normal temperature.

|

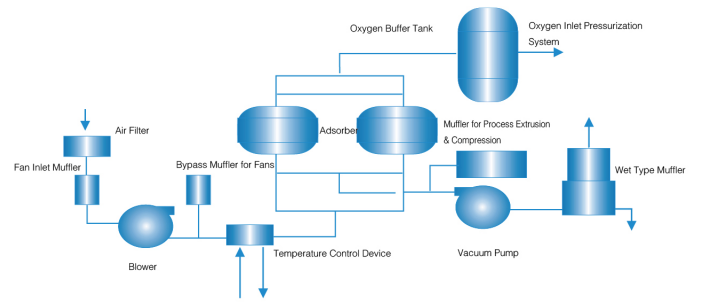

Main Characteristics of the Equipment | More moving parts, complicated structure, more control elements of supporting instruments; centrifugal air compressor (or no-oil air compressor), steam-water separator, air purifier, heat exchanger, piston expansion device, separation tower for filters | Fewer moving parts, simple equipment, fewer control elements of supporting instruments. Blower, adsorption tower, vacuum pump, oxygen storage tank |

Operating Features | With complicated operation, the equipment may not be used at any time. As the equipment shall be operated under the ultralow-temperature condition, therefore, it is required to have the process of pre-cooling startup and ineffective energy consumption (low-temperature liquid accumulation and heating purge). If the running & stop time is much longer and the number of times is much more, the finished product gas* s unit consumption is correspondingly increased. There are many complicated operating control & monitoring points. It is required to regularly stop the equipment for overhaul and maintenance. The operation personnel need to accept the long-term professional technical training and have rich practical operation experience. | With simple operation, the equipment may be used at any time. The operating control and monitoring are realized by the PLC. The time to start and stop the equipment is very short, less than 5 minutes. Short-term or long-term continuous operation or stop doesn't affect the operating conditions. Do not regularly stop the equipment for overhaul and maintenance. After accepting the short-term technical training, the operating personnel may operate the equipment. |

Application Scope | Need oxygen, nitrogen, hydrogen and other gas products; the oxygen purity is 99.5% | Obtain the single gas, with the purity of 90-95% |

Maintenance Features | Due to high precision & requirement of the centrifugal air compressor, condensation steamer and expansion device, the overhaul for the heat exchanger in the fractionation tower shall be completed by the personnel who have accepted the professional technical training with rich experience. | The maintenance for the blower, vacuum pump and program control valve belongs to conventional maintenance, and it may be completed by the general maintenance personnel. |

Civil Engineering & Installation Features | With complicated unit and large covering area, need special workshop, fractionation tower and anti-freezing foundation, and have high engineering construction cost. The equipment shall be installed by the installation team with rich air separation equipment installation experience, and have long installation period, high difficulty (fractionation tower) and expensive installation cost. | The equipment has small outline dimension, and small covering area, with conventional installation, short installation period and low cost. |

Automatic Program Safety | The number of units is much more. Especially, when the high-speed turbine expansion device is adopted, it is easy to affect the normal operation of the equipment due to faults. In addition, the skilled operating personnel are required to stay on the site. If the equipment is operated under the over lOP and high-pressure conditions, this will bring explosion risks and the related cases have occurred up to now. | After being started, the equipment may carry out the full-automatic program control to achieve the unmanned operation. As the equipment is operated under the normal temperature & low pressure, there are no unsafe factors, explosion risks or cases. |

Purity Adjustment | Inconvenient purity adjustment, high oxygen generation cost | Convenient purity adjustment, low oxygen generation cost |

Oxygen Generation Cost | Energy consumption: -1.25kwhm³/h | Energy Consumption: Less than 0.35kwhm³/h |

Total Investment | High investment | Low investment |

You need a product

You May Like

6YRS Zhejiang Zhengda Air Separation Equipment Co., Ltd.

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash