ZMO Membrane Separation Mobile Oxygen Enrichment Equipment

group nameZMO Membrane Separation Mobile Oxygen Enrichment Equipment

-

Min Order1 piece

brand nameZHENGDA PSA Air Separation Plants

modelZMO

payment methodL/C, T/T

-

update timeFri, 15 Apr 2022 14:10:48 GMT

Paramtents

Oxygen Output 10-20000Nm3/h

Oxygen Enrichment Purity 25~35%

Energy-saving 10-27%

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Membrane Separation Oxygen Enrichment Generation Principle

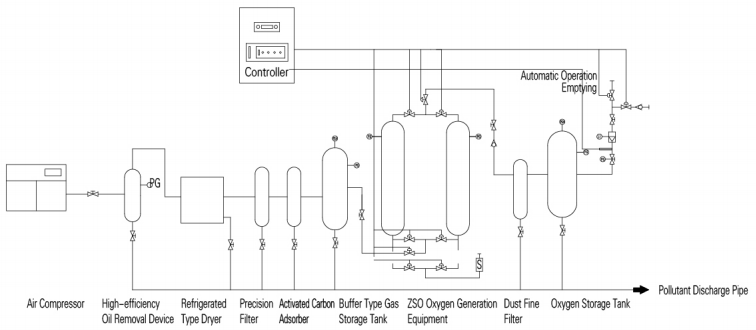

The equipment is mainly composed of the centrifugal fan, filtration system, vacuum pump, membrane separation system, steam-water separation system, control system and pressure stabilizing system. Its operating principle is to utilize the raw material air' s speed difference at the time of passing through the membrane module to achieve the purpose of separation or specified component enrichment. Under certain action of driving force, for gases whose permeation rate is quit fast, like water vapor, oxygen and carbon dioxide, they are enriched on the permeation side of the membrane after passing through the membrane; for gases whose permeation rate is relatively slow, like nitrogen and argon, they are retained and enriched on the retention side of the membrane, so as to achieve the gas separation.

Application Advantages of Oxygen-enriched Combustion-supporting Technology

1. Enhance the flame temperature.

2. Reduce the ignition temperature of fuel.

3. Accelerate combustion,promote combustion safety,and eliminate pollution, so as to meet the environmental protection requirements.

4. Increase the utilizaztion ratio of heat.

5. Lower the coefficient of excess air.

6. Reduce the smoke& gas discharge after combustion.

Oxygen enrichment is widely used for combustion support, energy conservation and environmental protection of kilns (glass, cement and ceramics), industrial boilers, heating furnaces, incinerators, thermal coal furnaces, air heating furnaces and smelting furnaces of fuel oil, fuel gas and fuel coal; catalytic cracking, wastewater treatment, engines, oxygen enrichment (coal) gas generation, oxidation reactions, fermentation and other fields also adopt the oxygen-enriched technology and obtain better economic benefit. According to the scientific information research, based on the heat efficiency of kilns used by customers, adopting the oxygen-enriched & energy-saving technology may gain the certain benefit on output increase and consumption reduction, so as to improve the product quality, lengthen the service life of furnaces, and eliminate exhaust emission, to obtain the significant comprehensive benefit.

You need a product

6YRS Zhejiang Zhengda Air Separation Equipment Co., Ltd.

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash