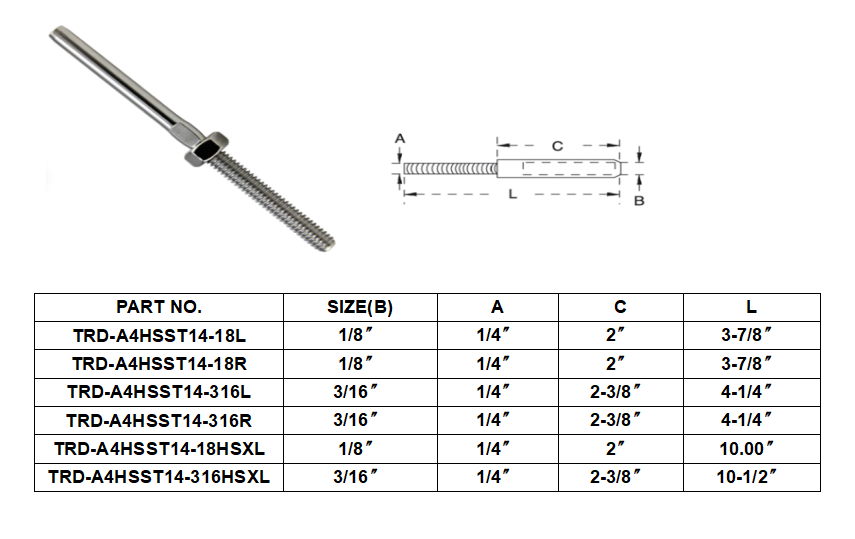

Stainless Steel 1/8 Cable Railing Hardware | Hand Swage Stud with Nut and Washer for 1/8 Wire Cable

group nameCable Railing Hardware Supply

-

Min Order1000 piece

brand nameTERADA Custom Hardware Supplier

modelTRD-A4HSST14

payment methodL/C, D/A, D/P, T/T

-

update timeFri, 25 Jun 2021 12:08:36 GMT

Paramtents

Material Marine Grade 304 or 316, Stainless Steel

Process CNC machining,Casting,Stamping,Hot forging

Requirements Good quality material, high surface, no rust

Package Thickened Woven Bag,Five Ply Cartons, Pallets

Application Wire Rope, Tensile Structure,Cable Railing

Relative Hardware Swage Stud, Swage Terminal, tensile rod

Packging & Delivery

Min Order1000 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, Westem Union