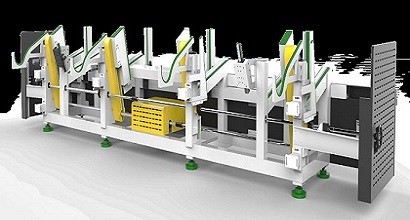

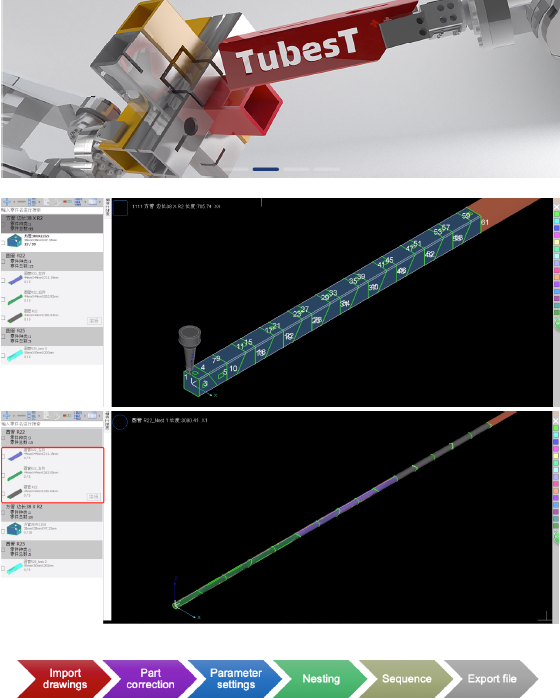

CNC Fully Automatic High Precision Fiber Laser Cutting Tube Machines

group nameCNC Fiber Laser Tube Cutting Machines

-

Min Order1 unit

brand nameBossray CNC Tube bender and Lasertube Manufacturer

modelFLT-6020HT

payment methodT/T

-

update timeSat, 06 Dec 2025 16:31:03 GMT

Paramtents

Cutting diameter 20 to 200 mm

Maximum tube weight 500 kgs

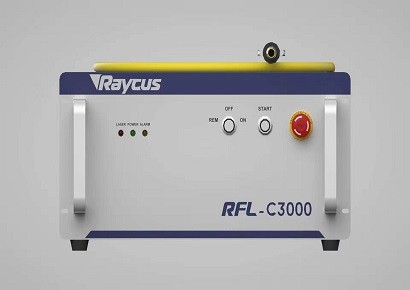

Laser type Fiber Laser

Laser source IPG RAYCUS MAX

Cutting Speed 80m/min

Packging & Delivery

Weight6000kg / unit

Min Order1 unit

Briefing

Detailed

|

Model |

FLT-6020HT |

|||

|

Effective Tube Cutting Length:

|

6000mm |

|||

|

Laser Output Power: |

6000W / 3000W / 1500W |

|||

|

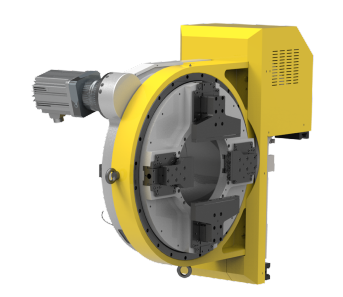

Effective Round Tube Cutting Diameter:

|

Φ20-200mm |

|||

Effective Square Tube Cutting Diameter: | 15x15, 150x150 | |||

Rectangular tube Edge Length: | 15x150 | |||

X/Y-axis positioning accuracy: | 0.05mm/m | |||

X/Y-axis repositioning accuracy: | 0.03mm | |||

X axis maximum speed: | 140m/min | |||

Y axis maximum speed: | 100m/min | |||

Rotating accuracy: | ±0.1° | |||

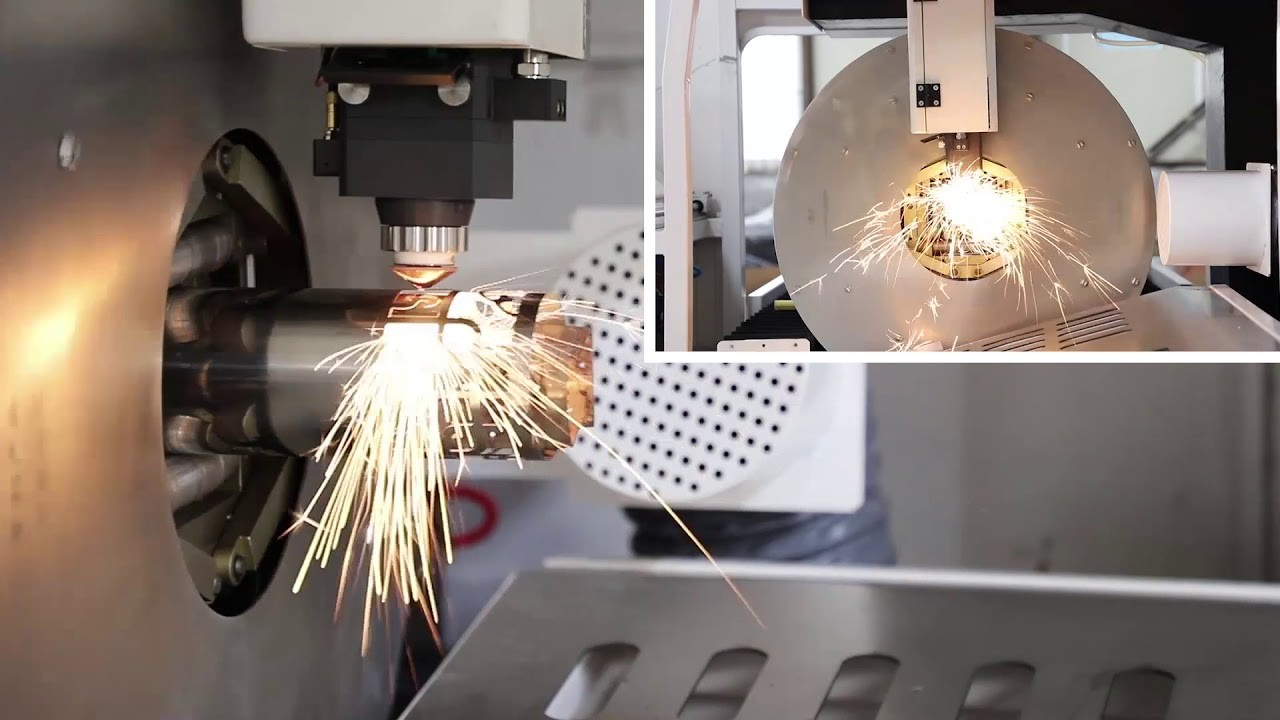

- 1Gas-saving Nozzle with Steady Flow

- Cutting performance and efficiency are improved by maintaining gas flow steady with little turbulence.

- 2Bossray Lightning

- The lightning-quick piercing process combined perfectly with BossrayGenius completes the whole piercing just during the laser cutter head moves down on Z-axis.

- 3Angle Steel and Channel Steel Cutting

- Angle steel and channel steel cutting are standard with no need for additional installation.

- 4Four-side Edge Searching, Higher Precision

- Optimized edge searching method and algorithm guarantee higher cutting precision and better steadiness of the laser cutter.

You need a product

You May Like

6YRS BOSSRAY MACHINERY

- Nearest port for product export

- Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, Credit Card, Westem Union