FromRubber Custom Injection Molded Plastic Shells for Electric Car Dashboard

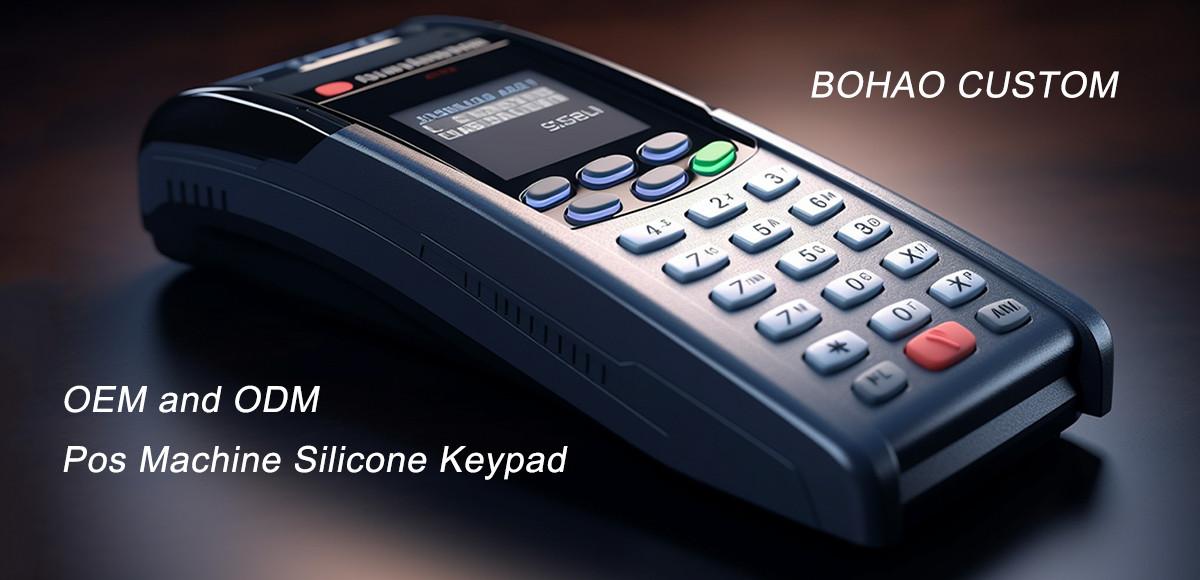

group namePlastic Enclosure

-

Min Order1 piece

brand nameFromRubber Silicone & Plastic OEM Manufacturer

payment methodT/T, D/P D/A, Credit Card, PayPal, Westem Union, Cash

-

update timeMon, 29 Apr 2024 20:06:33 GMT

Paramtents

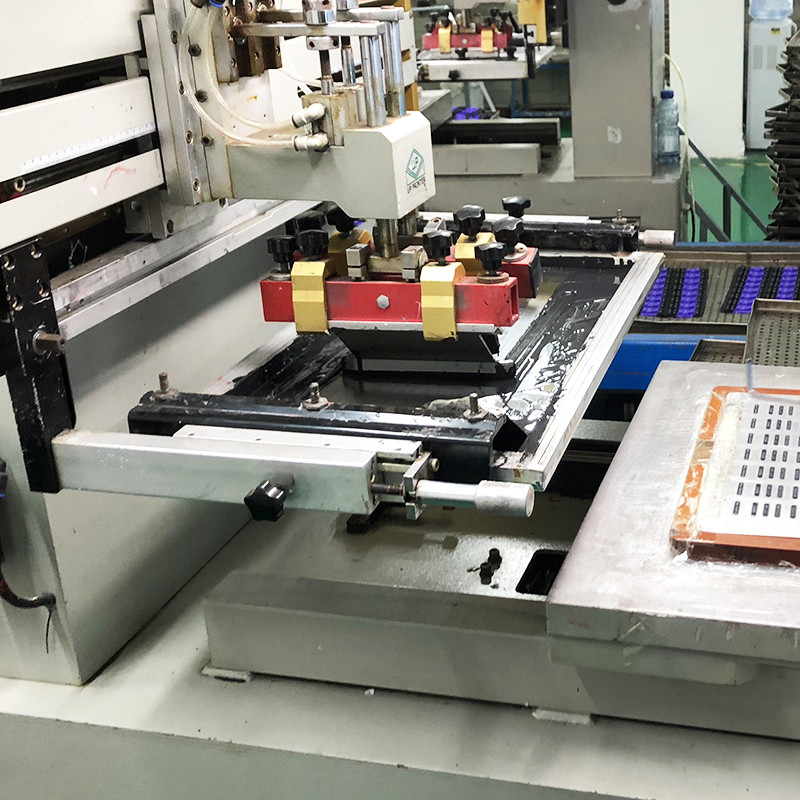

Design 3D Drawings or Objects

Surface Polishing

Service Free Consult

MOQ 1000pcs

Application Electric Car Dashboard

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- FOB shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union, Cash