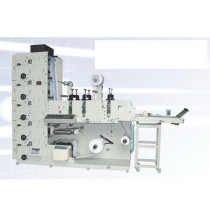

Label Printing Equipment

group nameAdhesive Paper Printer Machine

-

Min Order1 piece

brand nameJota Machinery

modelJTB-4100

payment methodL/C, T/T

-

update timeThu, 27 Sep 2012 16:51:48 GMT

Paramtents

PLC Emerson

Inverter Motor Innovance

Auto Tension Control System Yes, 2 sets

Unwinding /Rewinding Diameter 1000mm

Anilox Roller 1000LPI, Ceramic Anilox Roller

Color Number 2 color, 4 color

Temperature Control Auto Temperature Control

EPC for Web Guide

Dimensions(L*W*H) 7500 x 2700 x 3500mm

Ink Pump Available

Packging & Delivery

Min Order1 piece

Briefing

1. PLC and Auto Tension

2. Frequency Inverter

3.Ceramic Anilox Roller

Detailed

Machine Description:

Specification:

1. Flexographic Printing Machine adopts programmed control system and meter counter. One working length is setup on the control panel, after got to the setup data, the machine will automatically stop and alarm.

2. Flexographic Printing Press adopts famous brand from Japan frequency inverter to control AC motor with stable function.

3. Flexographic Printing Press adopts pneumatic lifting system for printing cylinder.

4. Start in lower speed and full loading. When lifting or reducing speed, the tension is stable, and low noise

5. Ceramic Anilox roller with the material has a full touch when in high speed. It has an advantage of high registration and stereo perception.

6. Flexographic Printing Press adopts special oblique gear and printing size is in high precision.7. The transmission roller is from Taiwan, it has balance treated and smooth run.

8. Flexographic Printing Press adopts recycle air system which is made up of air blower, air sucker and thermal heater, and it adopts automatic temperature section control. And the cooler is available.

9. Flexographic Printing Press adopts hot air blower and cold air blower for fast ink drying simultaneously.

10. Each printing unit has a clutch and seperate registration system with easy operation.

11. Flexographic Printing Machine adopts EPC for material edge tracking to achieve a good smooth rewinding.

12. Flexographic Printing Press adopts double position unwinding/rewinding stand to realize non-stop exchange.

If you are interested in this machine,pls feel free to contact us.