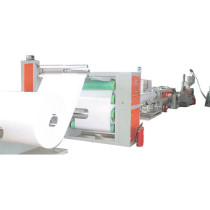

Double-Layer PP/PS Sheet Extruder

group nameSheet Extrusion Line

-

Min Order1 piece

modelFJL-660PC II

-

update timeTue, 31 Jul 2012 01:03:49 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

It mainly uses in producing double-layer plastic flake board of PP,HIPS,GPPS,PE etc.

The screw of the extrusion machine uses big ratio of length and diameter, its formed effect is nice, the thickness of the flake board is equal and the running speed is same.

The machines use advanced hydraulic pressure high speed net changing fitting without stopping the machine, so the operation is convenient, the function is excellent, and it can improve the productive efficiency.

It has high precision distributing fitting and T-style mold head, and it can ensure that the running speed coming out of the mold and pressure are all equal.

Pressing roller uses worm wheel to adjust, the operation is convenient and the precision is high.

The surface of the pressing roller is brighter than the mirror, the temperature of surface of the roller is equal, so the flake board produced is clean and bright, and the thickness is equal.

The machine can select different plastic to produce the compound flake board with different colors according to different products.

Main Technical Parameter:

Model | FJL-660PC II | FJL-1500PC II |

Material Used | PP、PS、HIPS、PE | |

Sheet Width | ≤680mm | ≤1500mm |

Sheet Thickness | 0.3-2.0mm | |

Layer | 2 | |

Max. Extrusion Capacity | ≤210Kg/h | ≤350Kg/h |

Main/Auxiliary Screw Dia. | 110-80mm | 80-120mm |

Roll Dia. | 350mm | 300-450-450mm |

Main/Auxiliary Motor Power | 45-30KW | 30-75KW |

Overall Power | 150KW | 200 |

Overall Dimension | 12.5*2.0*2.2 | 13.5*2.2*2.3 |

Weight | 8.5T | 9.5T |

Power Supply | 380V/50HZ, Tri-phase, Four-wire | |