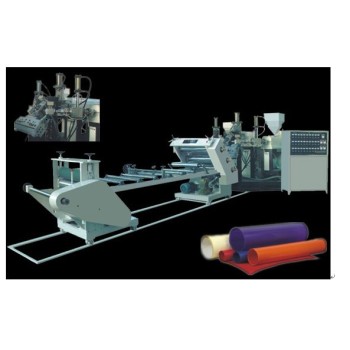

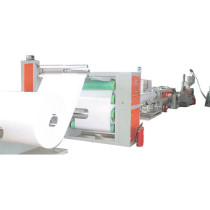

Three-Layer Plastic Sheet Extruder

group nameSheet Extrusion Line

-

Min Order1 piece

modelFJL-660PC III

-

update timeTue, 31 Jul 2012 01:01:20 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Usage:

FJL-660PC III Three-layer Plastic Sheet Extruder is designed on the base of Double-layer Plastic Sheet Extruder and adopts advanced technology from domestic and abroad. It’s applicable to produce Multilayer PP/PS/PE plastic sheet, which is used to make disposable water drinking cups, ice-cream cups, disposable cup/bowl for yoghurt, lids, dishes, plates and etc.

Major Construction Features:

1、The main parts, such as screw, barrel, adopt superior 38CrMoAIA material, which is featured by high hardness, anticorrosive advantages

2、The special designed screw adopts big L/D Ratio to ensure the good plasticizing, stable extrusion and high output.

3、T-Die: It’s made of super quality alloy steel and adopts adjustable restrictor bars, providing the even pressure of the plastic flow at the die lips. It ensures even thickness of the boards with adjustable lips.

4、Screen Exchanger: It adopts hydraulic style fast screen exchange with double filters.

Main Technical Parameter:

Model | FJL-660PC III |

Material Used | PP、PS、HIPS、PE |

Sheet Width | ≤680mm |

Sheet Thickness | 0.3-2.0mm |

Layer | 3 |

Max. Extrusion Capacity | ≤250Kg/h |

Main/Auxiliary Screw Dia. | 80-110-80 |

Roller Dia. | 350mm |

Main/Auxiliary Motor Power | 30-45-30KW |

Overall Power | 200KW |

Overall Dimension | 11.5*2.1*2.2 |

Weight | 10T |

Power Supply | 380V/50HZ, Tri-phase, Four-wire |