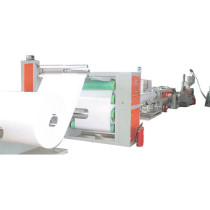

PET Sheet Extrusion Line

group nameSheet Extrusion Line

-

Min Order1 piece

modelFJL105/65-1000

-

update timeFri, 03 Aug 2012 01:33:05 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

1. It adopts co extrusion technology to produce multi-layer co-extruded PET sheet, such as APET/PETG, PETG/APET/PETG, APET/RPET/APET. It is widely used in compression molding, printing, metal packaging and etc.

2. Equipped with feed box, stratified homogeneous and the different proportion can be regulated.

3. Horizontal pressure structure, operation and maintenance more convenient.

4. Roller have independent power, line speed and extruder speed synchronous control.

Model | Used Material | Screw Dia. | Layer | Sheet Thickness | Sheet Width (mm) | Max. Extrusion Capacity (KG) | Installed Power (KW) |

FJL90-1000 | APET,PETG,RPET | φ90×33 | 1 | 0.16-1.4 | ≤850 | 200-300 | 275 |

FJL105-1000 | APET,PETG,RPET | φ105×33 | 1 | 0.16-1.4 | ≤850 | 300-400 | 320 |

FJL90/50-1000 | APET,PETG,RPET | φ90×33 φ50×32 | ≤3 | 0.16-1.4 | ≤850 | 250-350 | 326 |

FJL105/65-1000 | APET,PETG,RPET | φ105×33 φ65×32 | ≤3 | 0.16-1.4 | ≤850 | 350-450 | 385 |

FJL120/65-1000 | APET,PETG,RPET | φ120×33 φ65×32 | ≤3 | 0.16-1.4 | ≤850 | 450-550 | 435 |