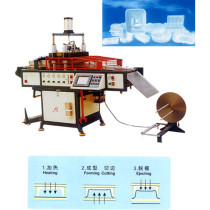

Plastic cup thermoforming machine

group nameThermoforming Machines

-

Min Order1 piece

-

update timeFri, 23 Dec 2011 23:50:16 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Main Features:

|

Machine Description |

PLUG ASSISTED PRESSURE

THERMOFORMING MACHINE –

FULL AUTOMATIC |

|

Model |

FJL-660SB-D |

|

Approximate Forming Area |

650 x 320 mm |

|

Stroke / min

approx. during production |

15-30 (up to material, its thikcness and forming deepth) |

|

Approx. Sheet width required for feeding. |

500 – 660 mm in rolls. |

|

Mode of cutting arrangement. |

In mould automatic |

|

Sheet thickness

Range. |

0.20 – 2.0 mm |

|

Material |

PP,PS,PET,PVC |

|

Max.Draw depth,

i.e. cup length. |

170 mm |

|

Oil Pump Motor Power |

15KW |

|

Max. Sheet roll diameter. |

800 mm |

|

Heating arrangement |

Top + bottom

heating with IR Ceramic Heater, total 15 heating zones. |

|

Temperature Controller & Thermocouple. |

PID

K-Type |

|

Type of Mould |

Multi cavity

1 - 4 row. |

|

Water consumption |

0.5-1.0m3/h(Circle) |

|

Gas Consumption: |

1.3-1.6m3/min, 0.6-0.8Mpa |

|

Approx. Electricity Consumption |

45KW/hr |

|

Approximate Dimension |

3550×1330×2350mm |

|

Approximate Weight |

4800Kg |

|

ELECTRICITY PARTS |

Intelligent Temperature Controller:Huibang,China | |

|

Relay:OMRON, Japan | ||

|

Auxiliary Relay: OMRON | ||

|

Stretching servo motor: 4.4KW, Anchuan, Japan | ||

|

Feeding servo motor: 3KW, Anchuan, Japan | ||

|

PLC: DELTA, Taiwan | ||

|

Touch Screen: WEINVIEW,Taiwan | ||

|

Infrared Ceramic Heaters: Yunpai, China | ||

|

Temperature controller module: Huanan, China | ||

|

Ammeter & Voltmeter: Huanna, China | ||

|

OIL CIRCUIT PARTS |

Overflow Valve: Yuken,Japan | |

|

Selector Valve:Yuken,Japan | ||

|

Oil Hydraulic Cylinder: Yuchi, China | ||

|

Cooler: Fangli, China | ||

|

AIR CHANEEL PARTS |

Electromagnetic Valve |

2 positions 5 ways: CKD |

|

2 positions 3 ways: CKD | ||

|

2 positions 2ways: SMC | ||

|

Pneumatic Cylinder: Yida, China | ||