Origin: Hunan, China (Mainland)

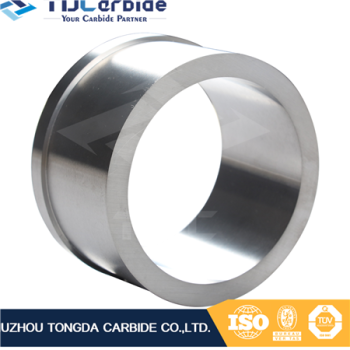

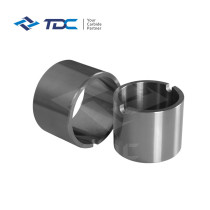

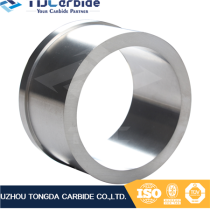

Brand Name: TDCType: Mechanical AccessoriesProduct Name: Tungsten steel wear sleevecolor: gray Material: alloySize: customGrade: YG8, YG6X, YS2T and so onOrigin: Zhuzhou, HunanName: Tungsten Cobalt CarbideGranularity: according to guest's requestSpecifications: According to the drawing sizeImpurities content: 0.01%The main metal content: 99.99The main performance: wear-resistant corrosion-resistantSurface treatment: rough or boutiqueUse: Bearing pump oil pump accessories

Product advantages: Carbide bushings on the shaft play a role in positioning or protection of the shaft to prevent shaft wear, while the hardness of the grinding shaft is low, the shaft can be used without quenching, thereby reducing the relevant parts Processing difficulty.Carbide bushings produced by our factory have the advantages of strong abrasion resistance, small friction coefficient, good toughness and long service life, and can be customized according to customer's requirements.Use: Carbide bushings have a wide range of uses, its role in the actual work and its application environment and purpose have a great relationship. In the field of valve applications, the bushing is installed in the valve cover to cover the valve stem so as to reduce the leakage of the valve and achieve the sealing effect. In the bearing application field, the use of the bushing can reduce the wear between the bearing and the shaft seat, Avoid the gap between the shaft and the hole to increase the role.Steel tungsten carbide sleeve detailsThickness: 8-30mmDiameter: 25-500mmLength: 100-2000mmAppearance: silver gray metallic lusterDensity: Purity: W≥99.95%Quality standard: GB / T 4187-1984 (tungsten rod) ASTM F288-90Supply status: Sintered or processedSize: Φ (25-500) mm × L (100-1000) m