Tungsten Carbide 3D Printer Carbide Nozzle

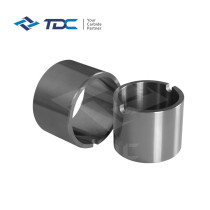

group nameTungsten Carbide Sleeve/Bush

-

Min Order1 piece

brand nameTDC

payment methodT/T, L/C, D/P D/A, PayPal

-

update timeWed, 19 Dec 2018 14:31:21 GMT

Paramtents

Name tungsten Carbide 3D Printer Carbide Nozzle

Standard ISO SGS CQC

Grade YG8/YG6 (can according to customer's request)

Brade TDC

OEM Yes

Used for pump and oil industries

Material tungsten carbide

Type Wear parts

Density 16.4g/cm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Factory Price of Tungsten Carbide 3D Printer Carbide Nozzle

1. Outstanding nozzle material properties: energy efficient / ensure high quality printing results

2. Calibration efforts are more stable (constant layer thickness even during extreme long print-runs as well as during high temperature print processes)

3. No extreme tempering effect. (Hardened Steel nozzles suffer a strong tempering effect caused by heat, which makes the steel softer)

4. Our flattened nozzle tip doesn't scratch glas beds unlike diamond / sapphire nozzles or not flattened nozzle tips

5. Another positive aspect is that there is no need for long lasting researches because it is anyway a reliable quality standard in the plastic extrusion industries and this lowered the developing cost of the 3D Printer nozzle and it grants a fast production after the crowdfunding campaign became successful

6. It has no tungsten nozzle tip in a steel or brass body instead our nozzle is completely made of a premium tungsten alloy which makes it more reliable and grants better thermal conductivity

Made of a premium tungsten alloy which is generally used in the plastics industry or for aerospace applications.

1. Corrosion resistance and long service life;

2. Excellent performance and high cost performance;

3. Not easy to wear.

1. Carbide nozzles are widely used in surface treatment, sand spraying, paint spraying, electronics, chemical processes and other industries.

2. Cemented carbide nozzles are also used in different applications, such as for line straightening, line guide and other aspects.

You need a product

You May Like

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal