High effiency motor stator winding production machine line

group nameStator production line

-

Min Order1 piece

brand nameNIDE

modelND-DZX-2

payment methodL/C, T/T

-

update timeTue, 19 Jul 2016 10:16:14 GMT

Paramtents

Automation type fully automatic

Certificate CCC

Condition New

Customized service Available

After-Sales Service Overseas Service Center Available

Machine color RAL9010 or as Per Customer Requirement

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Nide provides its customer with different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for stator production. equipped with product conveyor and mechanical arm, stator production line has been proved to be very effiency and high automation.

This stator production machine line can be used in different field, like BLDC, pump motor, car motor, induction motor, 3 phase motor ect. This stator production line including paper inserting machine, coil winding machine, coilwinding inserting machine, lacing machine, forming machine and testing machine.

This automatic stator production lineincluding paper inserting machine, coil winding machine, coil winding insertingmachine, lacing machine, forming machine and testing machine.

There are serval type of paper insertingmachine which can meet various requirement. Theproduction capacity ≤1s/slot(exclude the loading/unloading time). Primary qualification rate ≥99%, afterrework, the rate ≥99.9%

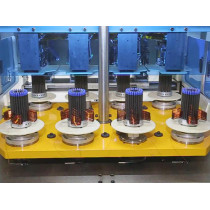

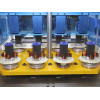

For the coil winding machine, it covers awide range of stator dimension and wire diameter. meeting the variousrequirement. The most efficient coil winding machine of this stator productionmachine line is equipped with four winding heads and eight operation stations.high slot filling rate, small slot opening stator coil winding. Winding mode,such as auto skip, auto cutting and auto indexing could be completed at a timesuccessively, parameter could be set in human-machine interface.Continuous/discontinues winding way and meets the 2 poles. 4 poles, 6 polescoils winding.

Coil winding inserting machine can insertstator coil and wedge into the stator slot automatically. It reduces the laborand improve the efficiency and accuracy.This machine is suitable for PolyesterFilm wedge roll material with fixed thickness and fixed width (width andthickness dimension is provided by customer). For the wire, both copper wireand alum wire are OK.

The lacing machine is controlled by PLC.Different lacing mode could be set such as slot lacing, interval lacing, andfancy lacing. Tooling change is fast and convenient. There are single lacingmachine, doulble station lacing machine and horizontal lacing machine.

The forming machine is used to do coilforming. Before lacing, the stator coil should do one time forming as it can bebetter to do lacing. After lacing, the stator coil should do final forming.Production capacity ≤14s/set (exclude loading/unloading time)

After all the above step, the statorproduction process is finished. Now it needs to do testing to check if it isqualified. The testing machine can test resistance, hi-pot, insulation resistanceect.

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right