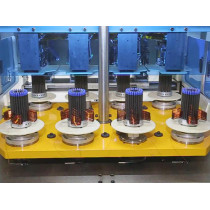

High effiency motor sator automatic manufacturing production line

group nameStator production line

-

Min Order1 piece

brand nameNIDE

modelND-DZX-4

payment methodL/C, T/T

-

update timeThu, 29 Sep 2016 13:50:00 GMT

Paramtents

Automation type fully automatic

Certificate CCC

Condition New

Customized service Available

After-Sales Service Overseas Service Center Available

Machine color RAL9010 or as Per Customer Requirement

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Stator line main feature

1.This production line is consisted of twoparts, conveyor and stand-alone machines respectively. The stator transferringand transforming process is fulfilled by mechanical arm between conveyor andstand-alone machines. While machine action is accomplished by handshakingcontrol between conveyor and stand-alone machines.

2.Each working station of this stator linehas a self-contained control function, and can work independently.

3.The conveyor is equipped with anindependent control system. It can lift, position, and stop stators.

4.With an automaticpositioning function, the paper inserting station can load and unloadstators.

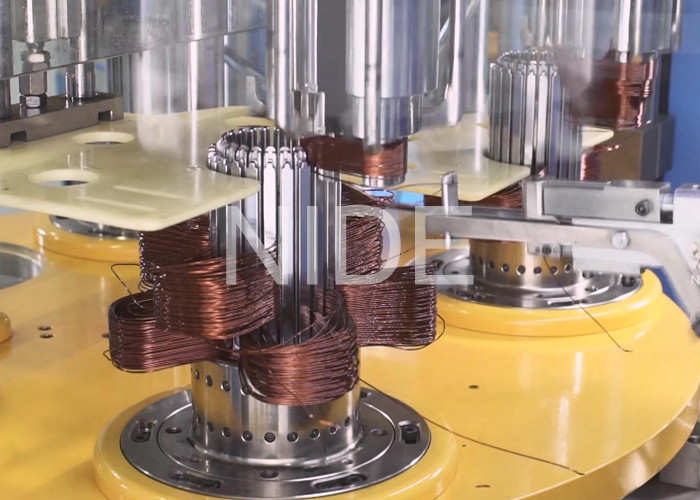

5.Mechanical robot is used to connect thepaper inserting station and auto coil inserting station during production. Itis stable during running. Stator position put by the mechanical arm is moreaccurate.

6.Mechanical arm is used to connect theforming station and conveyor during production.

7.Mechanical arm is used to connect thelacing station and conveyor during production. Lacing and knotting process canbe automatically done.

8.This stator line can automatically test thestator, then it will judge the qualified and unqualified stators soas to do next process.

This stator production line is consisted ofseveral machines, paper inserting machine, stator coil winding and coilinserting machine, lacing machine, forming machine.

Technical data of stator paper inserting machine:

Stator stack length: 20~90mm

Stator OD: max 135mm

Stator ID: 20~90mm

Folding height/width: 2~4mm/4~7mm

Insulation paper thickness:0.188~0.35mm

Efficiency:≈0.5s/s

Power: 380V/50/60HZ 0.75KW

Machine weight: ≈200kg

Machinedimension: (L)1200*(W)650*(H)1100mm

Main technical data of stator coil windingand coil inserting machine

Stator OD:≤φ150mm

Stator ID:≤φ110mm

Stack Height:30-120mm

Height of Coil:3

Appropriate Wire:φ0.18-φ1.2mm

Winding inserting mode:chained /same core

Pitch time:≤40s/pc

Air Pressure:0.6-0.8MPa

Power supply:380V 50/60Hz 15Kw

Weight ≈4000Kg

Dimension:(L)2000×(W)1300×(H)2300mm

Technical data of stator lacing machine

Stator OD:φ40-φ160mm

Stator ID:≤100mm

Stack Height:30-160mm

Height of Coil:≤65mm

Pitch time:≤14s/pc(24slots)

Air Pressure:0.4-0.6MPa

Power supply:380V 50/60Hz 6Kw

Weight:≈1500Kg

Dimension:(L)2000×(W)1100×(H)1900mm

Technical data of forming machine

Stator ID: 30~110mm

Stator OD: Max. 160mm

Stator stack length: 20~200mm

Winding overhang: Max 45mm

Displacement of cylinder: 20L/min

Power: 380V/50/60HZ 3.75KW

Machine weight: about 500Kg

Machine dimension: (L)1300*(W)1000*(H) 2400mm

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right