Sucker Rod Pump Spare Parts

group nameSucker Rod Pump

-

Min Order1 piece

brand nameSJ

payment method

-

update timeFri, 22 Mar 2013 11:01:19 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

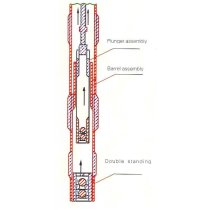

The company also can offer parts and components of sucker rod pump according to the use’s requirements, such as barrels, plungers (note: we can also offer Monel plunger), valve balls, seats and cages, etc. the common combinations of the material and surface treatment for the barrel and plunger manufactured in the company are as follows:

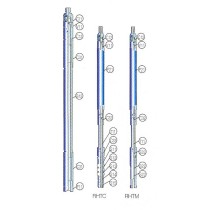

1. Nitrided Barrel and Spray Welded Plunger

The nitrided barrel is high in hardness, good in antiwear capacity and long in life (longer than that of the common barrel by 1.2 times).

The spray welded plunger is good in anticorrosion capacity. The welded layer of the plunger is melted together with the metal base, without layer difference of plating plungers and without crusting, flake and pinhole. It can be used in various well conditions.

2. Nickel-phosphor Plated Barrel and Spray Welded Plunger

Nickel-phosphor Plated Barrel is an anti-corrosion barrel. The nickel-phosphor plated layer has a uniform single phase structure, which can resist electrochemical reaction of micro-batteries and the plated layer is lower in porosity, tight in structure and stable in chemical property and it is not easy for the corrosive materials to enter in.

3. Chrome Plated Barrel and Spray Welded Plunger

4. Nitrided Barrel and Chrome Plated Plunger

5. Nickel-phosphor Plated Barrel and Chrome Plated Plunger

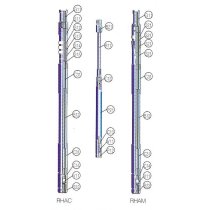

The materials used to make valve balls and seats for above 5 combinations of the barrel and plunger are: high-carbon, stainless steel, carbide alloy, ceramic, etc.

Their characteristics are:

1. Stainless steel seat is cheap and is most widely used.

2. Carbide alloy seat is high in hardness, large in density and strong in anti-corrosion capacity and applies to the wells with viscous crude or containing sand.

3. Ceramic seat is higher than that of carbon steel or alloy in anti-impact capacity and strong in anti-corrosion capacity. Its life is about 4.4 times as long as that of the common steel seat.