Rolling seam welding machine for sink production

- US $1.00

1 - 2 piece

group nameSink production line

-

Min Order1 piece

brand nameCONNUC

modelFN-100

payment methodL/C, D/P, Western Union, T/T

-

update timeSun, 24 Jul 2016 15:01:05 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

FN series is suitable for welding thestainless steel sink bowel and sink board together. When it works, the sinkturned around by even speed, the worker holds it and supports it manually tofinish the welding.

Machine Working Process and Step

Load the sink on the fixing jig of working table→ Start the machine→ The welding electrode rolls and sink start to go round andround,at the same time the worker holds and supports it manually→ Welding untilfinish→ Automatic back to the original position→ Unload the sink.

Rolling seam welding machine Description:

1. Using variable stroke pneumatic cylinders to avoid damage of upper and lower electrodes during movements.

2. Driving by 3-phase stepless speed regulating electrode, easy and stable adjustment of welding speed.

3. Both longitudinal or horizontal welding possible and meets the request of all kinds working pieces.

4. Robust & reasonable inner structure reduces welding weakness caused by heating.

5. The silver engine bearing with super conductiviy and it maximumly reduced the electrical energy loss.

6. Suitable for materials like low carbonsteel, stainless steel, widly used in metal fabrication industry includinghardware, home appliance, auto, basin making, can making, drum making,thin-wall container making, tank making etc.

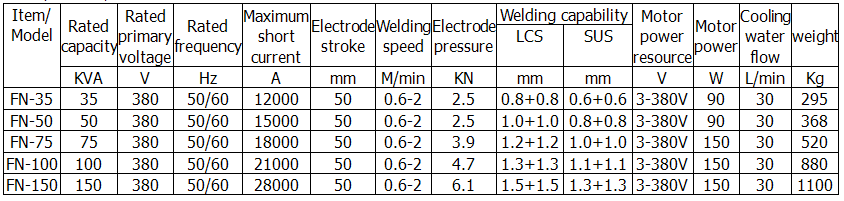

Technical specifications:

You need a product

You May Like

- Nearest port for product export

- Guangzhou, Shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, Westem Union, Cash