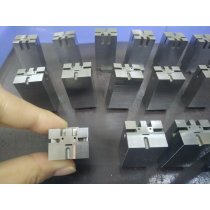

ISO Certification Wire EDM Parts Grinding Machining Inserts Of Connector

group namewire edm parts

-

Min Order1 piece

modelKR002

payment method

-

update timeFri, 12 Jan 2018 15:06:38 GMT

Paramtents

Place of Origin Dongguan, China (Mainland)

Brand Name Kingrui

Certification ISO9001:2008

Model Number KR002

Payment Terms T/T 50% as deposit 50% before shipment

Delivery Time Normally, simple parts, 5-7 days, complicated parts, 7-15 days. According to QTY and the complexity of drawing

Packaging Details PE film covered first, Plastic box, then carton last.

Supply Ability 1200-1500 units per month

Packging & Delivery

Min Order1 piece

Briefing

Detailed

ISO Certification Wire EDM Parts Grinding Machining Inserts Of Connector

Custom Attributes

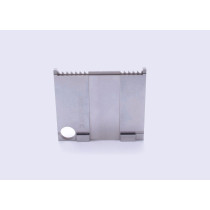

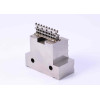

Mold Part Material:1.2379, Custom is available according to your require

Surface roughness:Ra0.4um Verticality:0.002mm

Accuracy for EDM:0.002mm Accuracy for Grinding:0.001mm

Hardness:58-60HRC Mian Machining:Grinding, EDM, WEDM and so on

The Descriptions of This Product

1. Perfect quality and competitive price.

3. Customized according to the customer’s requirements.

4. Tolerance: 0.001-0.005mm as the Drawings.

5. Main market: Japan, Europe and North American, Italy and so on.

6. We have wire EDM, CNC machining center, Japan Sodick supper- mirror and electro- discharge Machines to support our quality.

7. All the goods will be packed well before shipping; they will be shipped by air according to the weight.

| Product Name | ISO Certification Grinding Machining Wire EDM Parts of Inserts Of Connector |

| Precision Machine | Precision grinder, Wire cutting, EDM & etc. |

| Applied Software | PRO/E, Auto CAD, Solid Works, UG, CAD/ CAM/ CAE |

| Material | The wire EDM parts is made of 1.2379. And Stainess steel, Brass, Aluminum, Steel, Carbon Steel, Copper& etc. can be ready for per customer according to your demand. |

| Processing | For the these parts of display , their main processing technology is three steps: firstly grinding by the surface grinding machine, check this process without any problems after the next item, that is line cutting processing to ensure that all the process satisfied with customer drawings requirements, and then discharge processing. |

| Surface Finish | Polishing, PVD coating, DLC coating, etc. |

| Dimension | As per customer's request. |

| Tolerence Precision | +/ -0.001- 0.005mm/ can also be customized |

| Lead time | Base on the quantity of order( usually 5- 15 working days) |

| Quality System | Full inspection beforie shipping |

| Packing | *Eco-friendly PE film / plastic box / carton box |

*As customer's specific requirements | |

| Shipping | By sea, By air, By DHL, UPS, FEDEX& etc. |

| Near Port | Shenzhen and Hangzhou |

Our Facilities

Machining Facilities:

- CNC milliing machining

- Japan mitsubishi mirror EDM

- Taiwan qunji EDM

- Surface-grinding machine

- High-speed cnc engraving and milling machine

- Electric discharge machine

- Milling

- Wire-EDM

- Centerless grinder Machine and so on

Testing Facilities:

- 2.5 D Projector, Ordinary Projectors,

- Switzerland TRIMO Height Gages

- Japan Nikon Height Gages

- High/ Low Temperature Resistant Testers

- Two dimension

Packing and Delivery

| Packaging Details | 1) PE film covered |

| Delivery Detail | Usually 5-15 days, it depends on the quantity of your order. |

WE ARE PROUD OF KEEPING THE SPIRIT OF GOOD QUALITY !

PLEASE FEEL FREE TO CONTACT US

THANKS!

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- Express Delivery

- Acceptable payment methods

- T/T