Horizontal Machining Center

group nameHorizontal Machining Center

-

Min Order1 piece

brand nameDRC

modelDHM80

payment methodT/T

-

update timeMon, 30 Sep 2019 15:57:06 GMT

Paramtents

Power(W): 15KW

Spindle speed: 6000/10000rpm

Load of table(average load): 500kg

Dimension(L*W*H): Specific Model

Controlling Mode: Fanuc System

Positioning accuracy: 0.01

Spindle center to worktable surface: 50-700

Accuracy of repeated posit: 0.006

Product name: DHM-50A

After-sales Service Provided: Engineers available

Packging & Delivery

Min Order1 piece

Briefing

Detailed

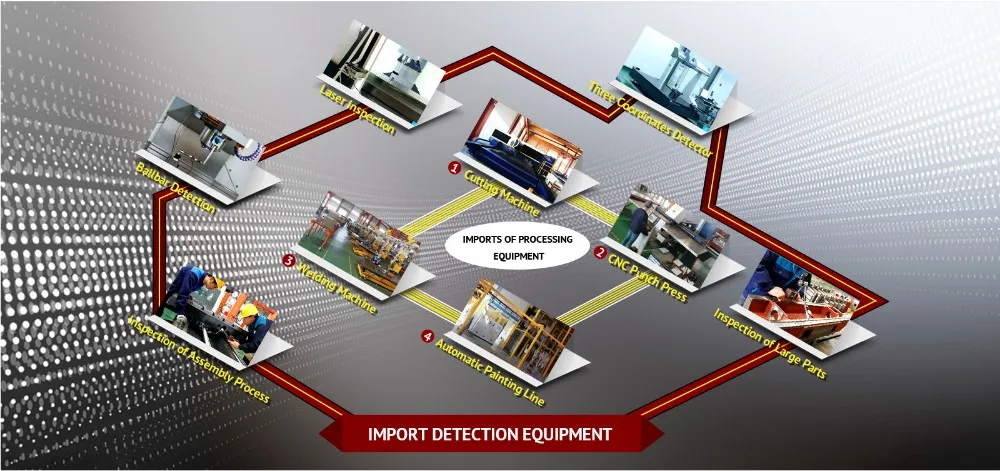

DRC Brand High Efficiency DHM80 Horizontal Chinese CNC Machining Center Price

Main Features

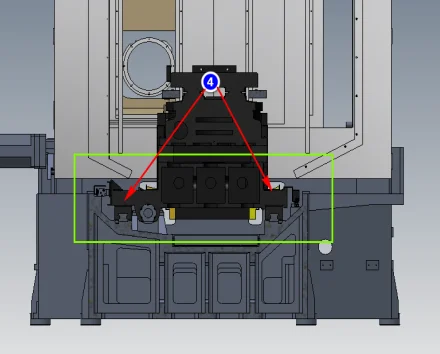

1.The X axis of the base is stepped type, the distance between the main shaft and the rear supporting rail is closer, and the stability of the machining accuracy is ensured; the column span is large, and the overall rigidity structure is more stable.

2.DHM-80 column thicker, other manufacturers thickness increased by 20%, more rigid.

3.DHM-80 base, Z shaft, support distance is wider, increase 40%, more rigid.

4.The DHM-80 table has greater supporting surface and more rigid rigidity.

5.DHM-80 adopt the R55 linear roller guide rail, and the other manufacturers are R45or50. The wire rail is bigger, the rigidity structure and the bed precision are more stable.

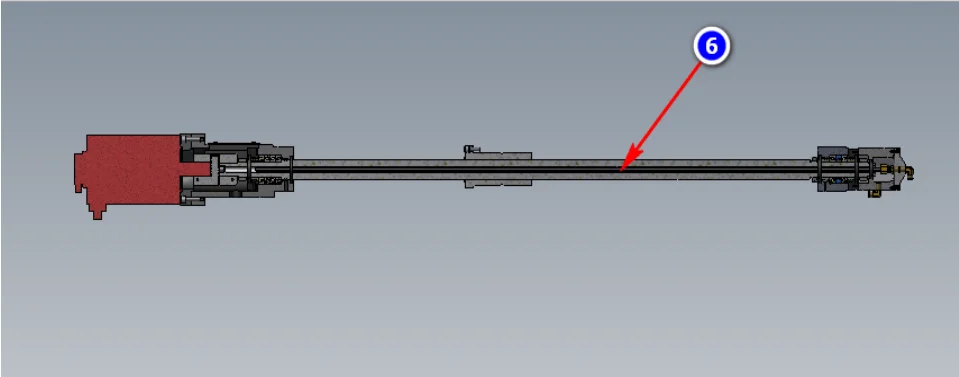

6. DHM-80 screw are hollow oil cooling screw, to avoid the screw in the course of movement, resulting in a large amount of heat, resulting in poor screw accuracy.

Spindle

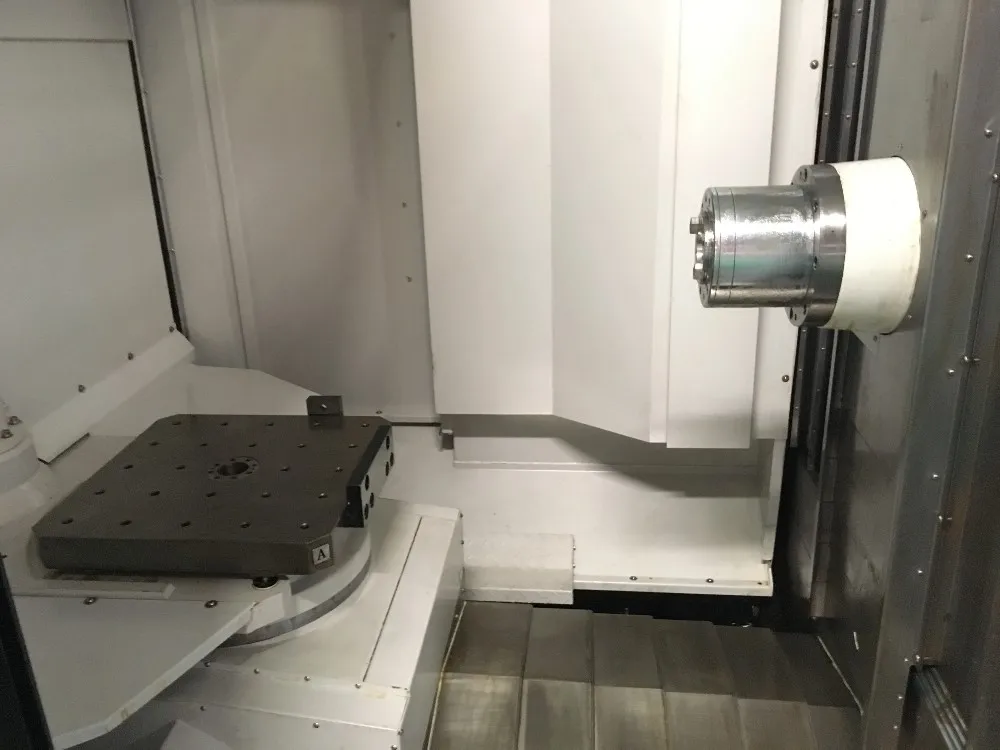

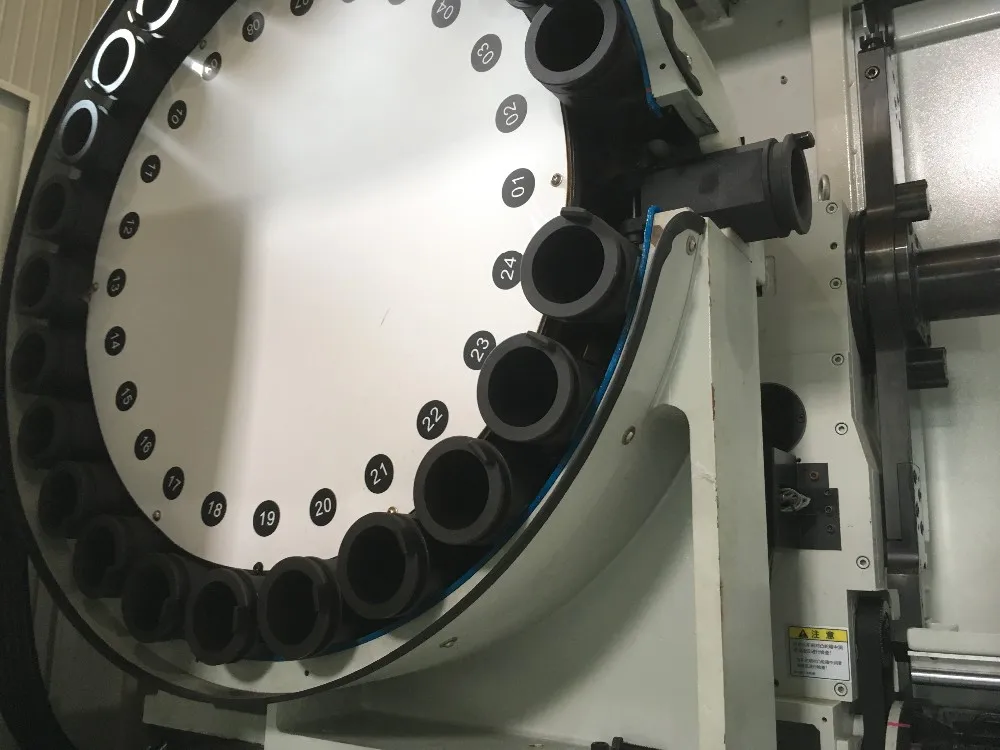

ATC(Automatic Tool Changer)

Automatic toolchanger is composed of tool maagazine and tool changing arms.Automatic toolchanger is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic toolchanger and other reasoons on precision.

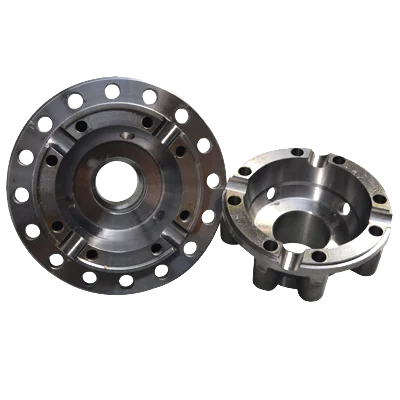

Processing Products

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

COMPANT INTRODUCTION:

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost..

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C