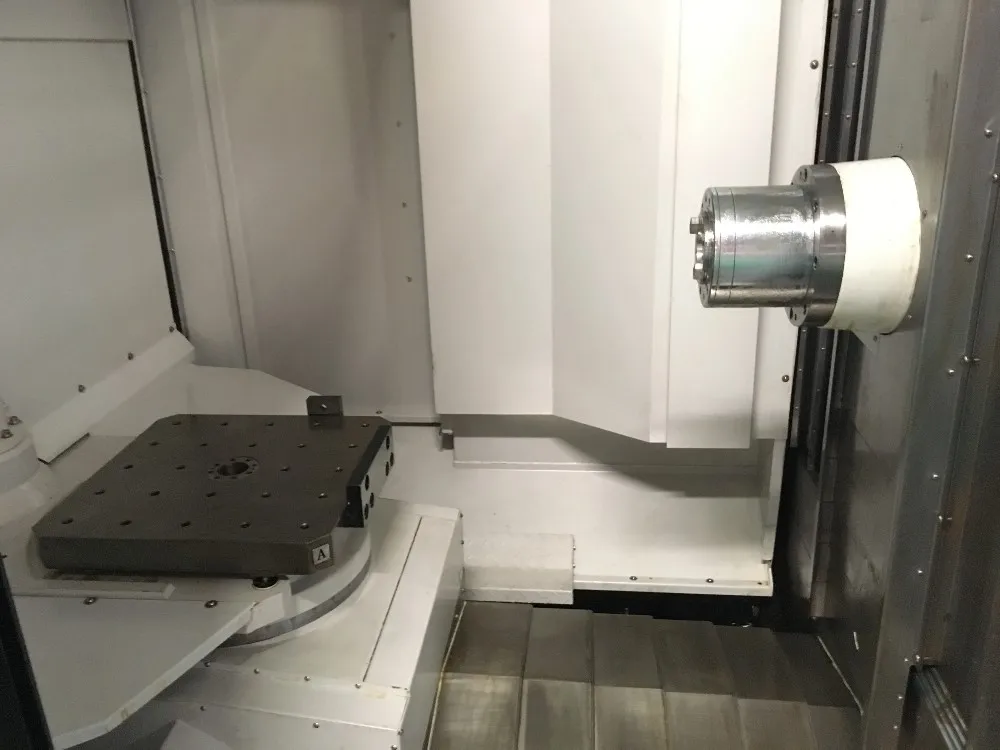

Double Work Table CNC Horizontal Machining Center

group nameHorizontal Machining Center

-

Min Order1 piece

brand nameDRC

modelDHM80-Double Worltable

payment methodT/T

-

update timeThu, 14 Nov 2019 13:10:25 GMT

Paramtents

Dimension(L*W*H): 3665/4515/6785mm

Controlling Mode: Fanuc System

Spindle speed: 6000/15000rpm

Accuracy of repeated posit: 0.005mm

Spindle center to worktable surface: 75-1275mm

Power(W): 15KW

Weight: 22000kg

Machine Type: Cnc Horizontal Machining Center

Positioning accuracy: 0.01mm

X-axis travel: 1300mm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

High Quality Double Work Table CNC Horizontal Machining Center For Sale

CNC horizontal machining center

DHM Owns Powerful Torque Force With Excellent Heavy Cutting Machining Capability.

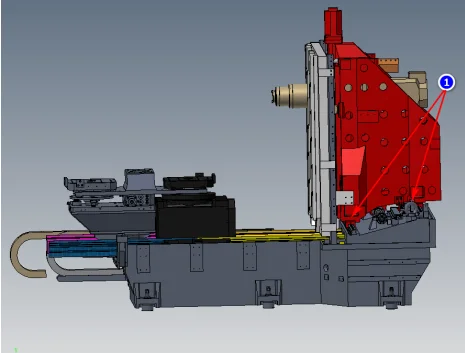

Unique Gear Type Spindle:

DHM Horizontal CNC Machining Center Uses The Drect Drive Spindle. Straight Type Spindle Motor Spindle With Wide Area, Low Speed And Full Power Output, To Meet The Large Amount Of Cutting Conditions And Cutting DHM-63/80/100/80T/110T/1250T Adopts Gear Type Spindle Variable Speed Device. Gear Type Main Shaft Head Are Integraly Cast Molding,Has A Higher Rigidity Than The Average Combined Type Main Shaft Structure, Improves The Stability Of The Machine. Cutting Ability Have More And More High Accuracy. Spindle Using Large Oilers NN Bearing Ultra Precision, Utra Rigid, There Processing Capability For Heavy Cuttng.

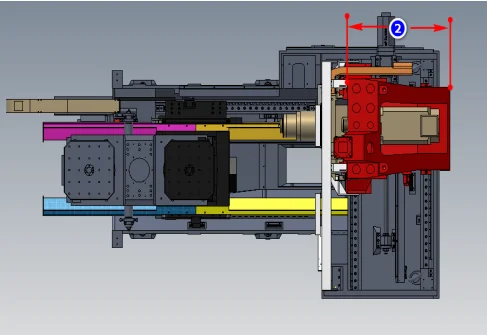

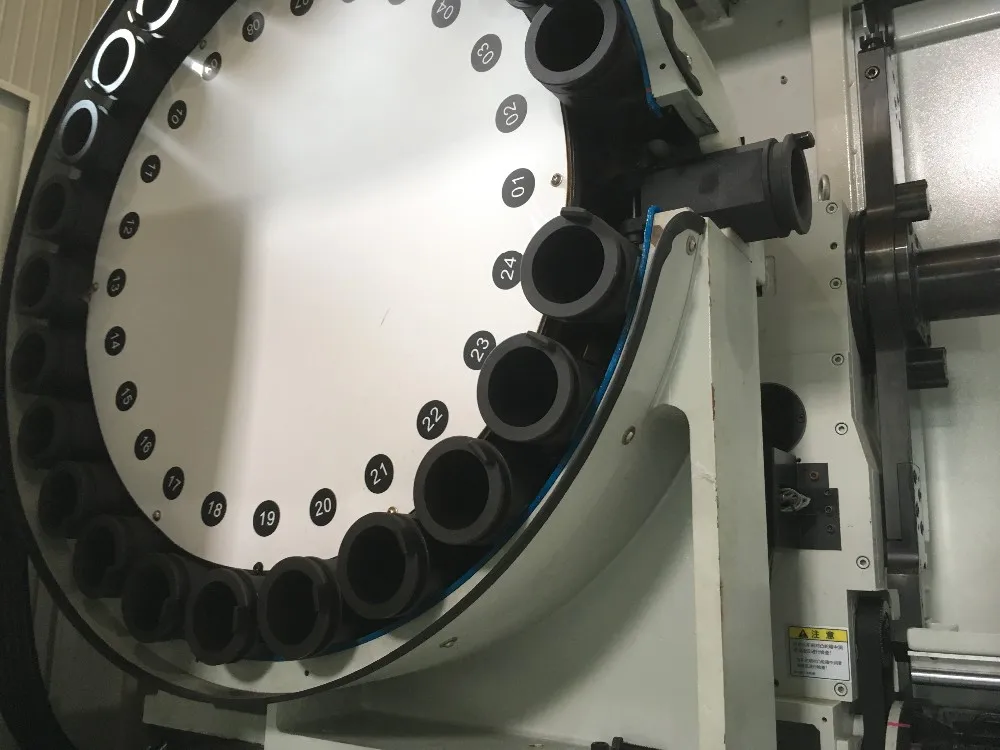

Tool Magazine:

Automatic Toolchanger Is Composed Of Tool Magazine And Tool Changing Arms. Automatic Toolchanger Is Installed Separately From Machine Tool With The Purpose Of Preventing Adverse Influences Of Vibration During Running Of Automatic Toolchanger And Other Reason On Precision. Tool Selection Adopts The Method Of Fixed Address In The Shortest Path. All Tools Return To Original Position, Therefore, The Problem Of Collision Between Large-Size Tools Is Only Considered In Initial Installation. Two-Way Tool Ma Adopts The Shortest Path.

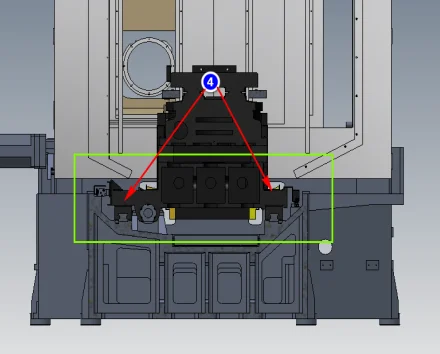

Machine Frame Structure Design Is Confirmed To Ensure High Rigidity:

The Structure Of The Machine Frame Is Been FEM Analyzed By ANSYS System To Guarantee High Stability Under High Speed And High Precision Machining. A Deformation Testing Is Simulated Under Lading Simulation To Ensure The Rigidity And Have Excellent Bending Resistance DHM Series Is Suitable For Heavy Cutting Horizontal Machining Center In Design Of X Axis Guide Rail With Large Span Section Difference, Make The Spindle And The Back Supporting Rail Distance Closer, In Order To Increase The Column Cutting Rigidity, And Fuly Meet Customer Demand Of Milling.

Double Work Table Form:

Horizontal CNC Machining Center Main Features

1.The X axis of the base is stepped type, the distance between the main shaft and the rear supporting rail is closer, and the stability of the machining accuracy is ensured; the column span is large, and the overall rigidity structure is more stable.

2.DHM column thicker, other manufacturers thickness increased by 20%, more rigid.

3.DHM base, Z shaft, support distance is wider, increase 40%, more rigid.

4.The DHM table has greater supporting surface and more rigid rigidity.

5.DHM adopt the R55 linear roller guide rail, and the other manufacturers are R45or50. The wire rail is bigger, the rigidity structure and the bed precision are more stable.

6. DHM screw are hollow oil cooling screw, to avoid the screw in the course of movement, resulting in a large amount of heat, resulting in poor screw accuracy.

The structure of the machine frame is been FEM analyzed by ANSYS system to gurantee high stability under high speed and high precision machining.A deformation testing is simulated under loading simulation to ensure the rigidity and have excellent bending resistance.

Spindle

DHM series uses the direct drive spindle. Srtaight type spindle motor spindle with wide area, low speed and full power output, to meet the large amount of cutting conditions and cutting.

Gear type main shaft head are integrally cast molding, has a higher rigidity than the average combined type main shaft strcuture, improves the stability of the machine.

ATC(Automatic Tool Changer)

Automatic toolchanger is composed of tool maagazine and tool changing arms.Automatic toolchanger is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic toolchanger and other reasoons on precision.

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C