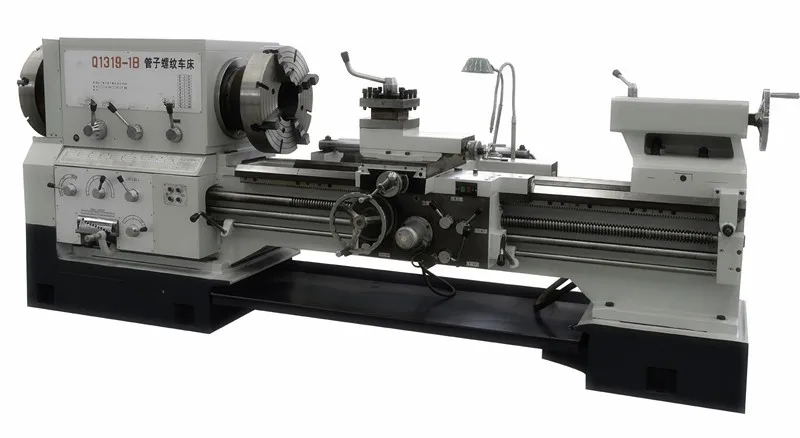

Newest Horizontal Pipe Threading big bore lathe machine

group nameConventional Pipe Threading Lathe

-

Min Order1 piece

brand namesanzheng cnc lathe machine

modelQ1319-1B

payment methodL/C, T/T

-

update timeThu, 26 Mar 2020 12:03:54 GMT

Paramtents

Condition: New

Automatic Grade: Manual

Certification: CE&ISQ

Type: Horizontal

Max.processing pipe diameter: 196mm drill pipe processing equipment

Model Number: Q1319-1B

After-sales Service Provided: Engineers available

CNC or Not: Normal

Power(W): 7.5KW

Spindle Hole: 200mm CNC Thread Chuck Lathe Rolling Machine

Packging & Delivery

Min Order1 piece

Briefing

big bore lathe machine

Detailed

Q1313 Oil&Gas Field Pipe Thread OEM Germany Lathe

Newest Horizontal Pipe Threading big bore lathe machine

Big Bore Pipe Threading Normal Lathe Machine Function:

Pipe thread lathe includes CNC pipe thread lathe and common type. DRC Machinery Pipe Threading Lathe Chinese lathe for process pipes belong to conventional type pipe thread lathe.Conventional type distance between center can be 1000mm, 1500mm, 2000mm, 2500mm, 3000mm, 3500mm, 4000mm, 4500mm, 5000mm or others. Feeding system can be automatic feeding according to customer requirement.

Compare with common lathe, pipe thread lathe has big spindle bore and double chuck which allows clamp and process big diameter pipes, oil sleeve parts, pipe coupling parts, drill pipe joints.The pipe threading lathe machine can complete turning of cylindrical, inner hole, and all kinds of screw threads, arc, cone and interior and exterior surfaces of solid of revolution. It is suitable for high-efficiency, high-volume, high-precision machining for some super-long parts of oil pipe and drill pipe joint etc.

Horizontal Pipe Threading Big Bore Lathe Product advantages:

1. Our company adopts advanced electric furnace smelting and tree brain sand casting technology to effectively avoid the defects such as sand holes and pores in the castings. The ingredients are tested by imported optical harmonic analyzer to ensure the quality of the castings and the secondary heat of the castings. Aging treatment, good stability.

2, the use of the overall floor-standing bed, the bed rail width, good sturdiness. The guide rail is subjected to high-frequency quenching treatment, and the sliding guide surface is attached with SD composite soft belt, which is wear-resistant and reduces the friction coefficient. The lead screw is integral (non-butt joint), the saddle is widened and thickened, the operation is more stable, and the cutting ability is improved.

3. The three boxes of machine tools are precision machined by CNC boring and milling machining center imported from Taiwan. The machining of other workpieces is completed by CNC machine tools and machining centers, which effectively guarantees the accuracy of the box and workpiece.

4. Accuracy inspection of the equipment Firstly, the Renishaw laser interferometer imported from the United Kingdom is used to detect the repeated positioning accuracy of the X and Z directions of the equipment. Finally, the comprehensive inspection and acceptance of the whole machine is carried out according to the enterprise standard, which effectively controls the precision of the machine tool.

Big Bore Metal Lathe Adhibition:

The Q series conventional pipe thread lathe mainly designed to process kinds of internal and external pipe threads including metric, inch, module, DP and taper threads, as well as having common functions of normal lathe such as processing the inner bore and end face of shafts and disks. The series lathe machine is widely used in industries including petroleum exploring, coal and mineral mining, chemical piping and geological prospection. It is high efficiency equipment in processing and repairing drilling pipe, drilling rod, thread coupling etc.

We are a professional manufacturer specialized in the cnc and conventional pipe threading lathe machine. CNC pipe threading lathe is a special model of CNC turning lathe ,mainly used in oil and gas field, machinery manufacturing, geological exploration, thread repair function and so on.

The bed of floor type is the whole structure. The rigidity and width of guide way on the bed of lathe is good enough.

thread making cutting lathe machine for steel pipes

pipe threading lathe screw-cutting lathe.

First step of the accuracy test of the equipment is testing the repeat accuracy of X and Y axis with Renishaw laser interometer imported from Britain.

Electric furnace smelting

big spindle bore mini metal hobby lathe.

We use electric furnace smelting, resin sand molding casting technology,avoid sand holes, stoma casting internal defect effectively.

high quality big bore gap-bed lathe machine.

SANZHENG Product advantages:

1we can can absolutely ensure the casting quality after the United States imported equipment precision spectrometer analysis.

2.With the super audio quenching treatment ,the hardness of Body guide rail can reach above HRC55 degrees, it can keep the hardness high accurate, and prolong the wear resistance and service life.

3.The lathe bed we produced is all research and development by our own engineers. These all can greatly increased the rigidity and are helpful to widen and Thicken the dragging plate,

4The large plate guide guide rail (X) is also go through the super audio quenching treatment, so it increased hardness and then could guarantee the service life of equipment more efficiently.

5 The equipment will firstly tested by the laser interferometer imported from Britain to test repeated positioning accuracy of X, Z direction in order to make sure the accuracy. Then the whole machine will be tested according to the National standard whole machine.

Our enterprise have got the ISO9001-2008 quality system certification and the European Union CE certification.

Feature

1. We set up TRB (tapered rolling bearings) on this lathe to increase the rigidity of the spindle.

2. Big spindle bore and double chuck allows clamp and process big diameter pipes;The spindle bore is very large and set up double chucks both front and back and you can choose electric chucks as you like.

3. Ultrasonic frequency quenched guide-ways are hard enough for good wear-resistance;Carriage and guide way contact surface pasted with Turcite B to maintain long-term accuracy,The slide rail f saddle is treated by wear-resisting layer coated, to avoid the crawling.

4. The slide rail f saddle is treated by wear-resisting layer coated, to avoid the crawling.

5. There are two types of speed change: Manual and step less.

6. Set up self lubrication system, and easy to maintain.

7.Integral machine bed adopts high strength iron to relize high rigidity and precision;

DRC Eight advantages

1. We research and develop Pipe threading lathe for more than 50 years, More than 200 staff ,9 professional engineers ,cover an area of 120,000 square meters.

2.CNC pipe threading lathe is a special model of CNC turning lathe ,mainly used in oil and gas field, machinery manufacturing, geological exploration, thread repair function and so on.

3. Customized service, we can make the pipe threading lathe according to clients' requirements.

4. We have our own casting workshop, guarantee good quality of the machine.

5. A big production capacity, always have machines in store, though so many orders we can also guarantee delivery time.

6. Certificate of CE and ISO

7. We have exported to Dubai , Malaysia,the USA ,Russia, Iran etc.

8. We make OEM for Knuth Germany about 8 year ,no quality problem , the orders are added every year.

E-mail:alice..........com

WhatsApp:86-155-6681-6110

You need a product

You May Like

- Nearest port for product export

- Dalian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C