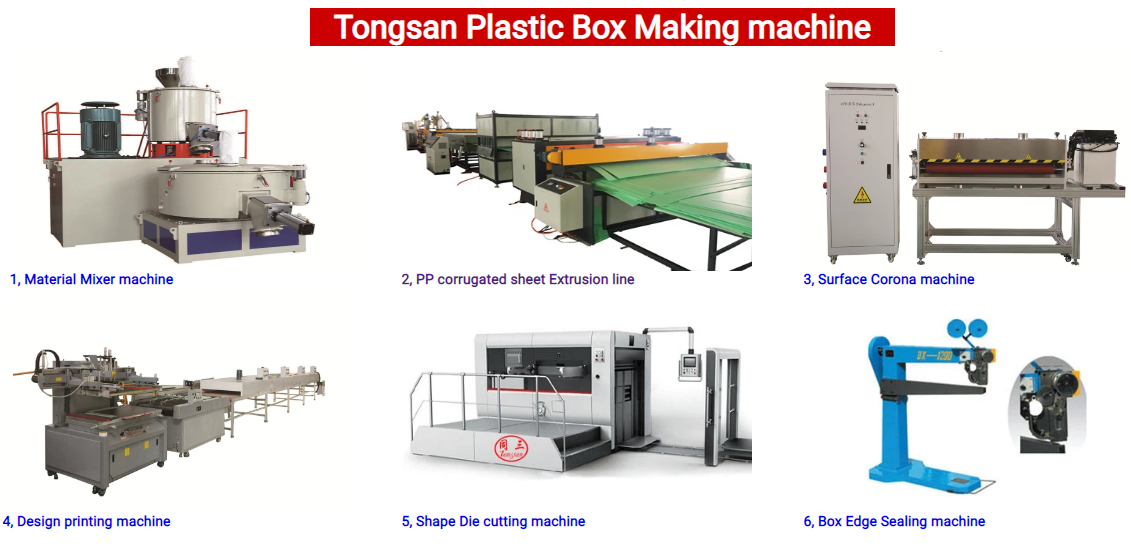

Fruit Packing case corrugated Plastic PP box hollow sheet manufacturing machine

- US $230000.00

1 - 5 set

- US $220000.00

6 - 10 set

- US $210000.00

11 - 20 set

group namePP Hollow Corrugated Sheet Extrusion Line

-

Min Order1 set

brand nameHEGU

modelTS-2300

payment methodL/C

-

update timeWed, 19 May 2021 11:40:10 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

Fruit Packing case corrugated Plastic PP box hollow sheet manufacturing machine:

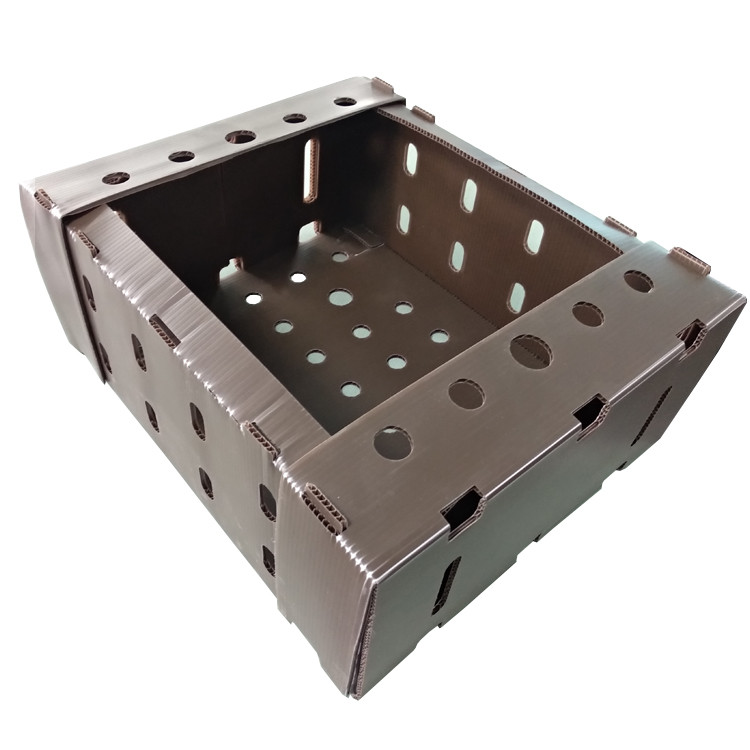

PP hollow sheet turnover box main material is a PP hollow sheet, and then after the pressure cut, torn edges, stitching, assembly and made of a series of processing flow.

Below is the example of processing for turnover box

1, the extrusion line produce the required PP hollow sheets with required width and thickness, and cut into required length. And collecting different sizes in different stacking.

2,Use the pressure cutting machine to cut the PP hollow sheet into required shape. Pressing action should be accurate, rapid, agile, and keep the board clean, in accordance with the provisions of a unified placed on the table.

3, the professional workers tear the extra edges according to the indentation from the pressure cutting machine, The tearing action should pay attention to the intensity. to ensure the board neat appearance, it is not allowed to produce flash and laceration because of strong tearing force.

4, stitching the two sheets by rivets, flat wire or welding, etc., the stitching seal can be sealed by fiber tape or glue or magic paste.

5, quality inspection. Quality inspection staff to perform full inspection, sampling, failure and other standard scrap process.

6, the qualified products will be packaged and stored, when folded, the packing box should be labeled and neatly put into storage.

The above is the whole process of making the turnover box from the PP hollow sheet. The turnover box made from PP hollow sheet has the advantages of light weight, non-toxic, tasteless, no pollution, flexural resistance, anti-aging, waterproof, moisture proof, abrasion resistance, corrosion resistance, , Can be reused repeatedly and a series of advantages, is a new type of green materials, logistics and packaging industry in the transport plays an important role in storage and turnover, can effectively protect the product from the external environment damage.

Comparing of canton packing material and PP hollow sheet material

1, Paper - paper fear of water, fear of tide, perishable, can not guarantee the quality of the product transport, there may be increased costs, so most of the cartons, cartons, cardboard and other paper products can only be used once.

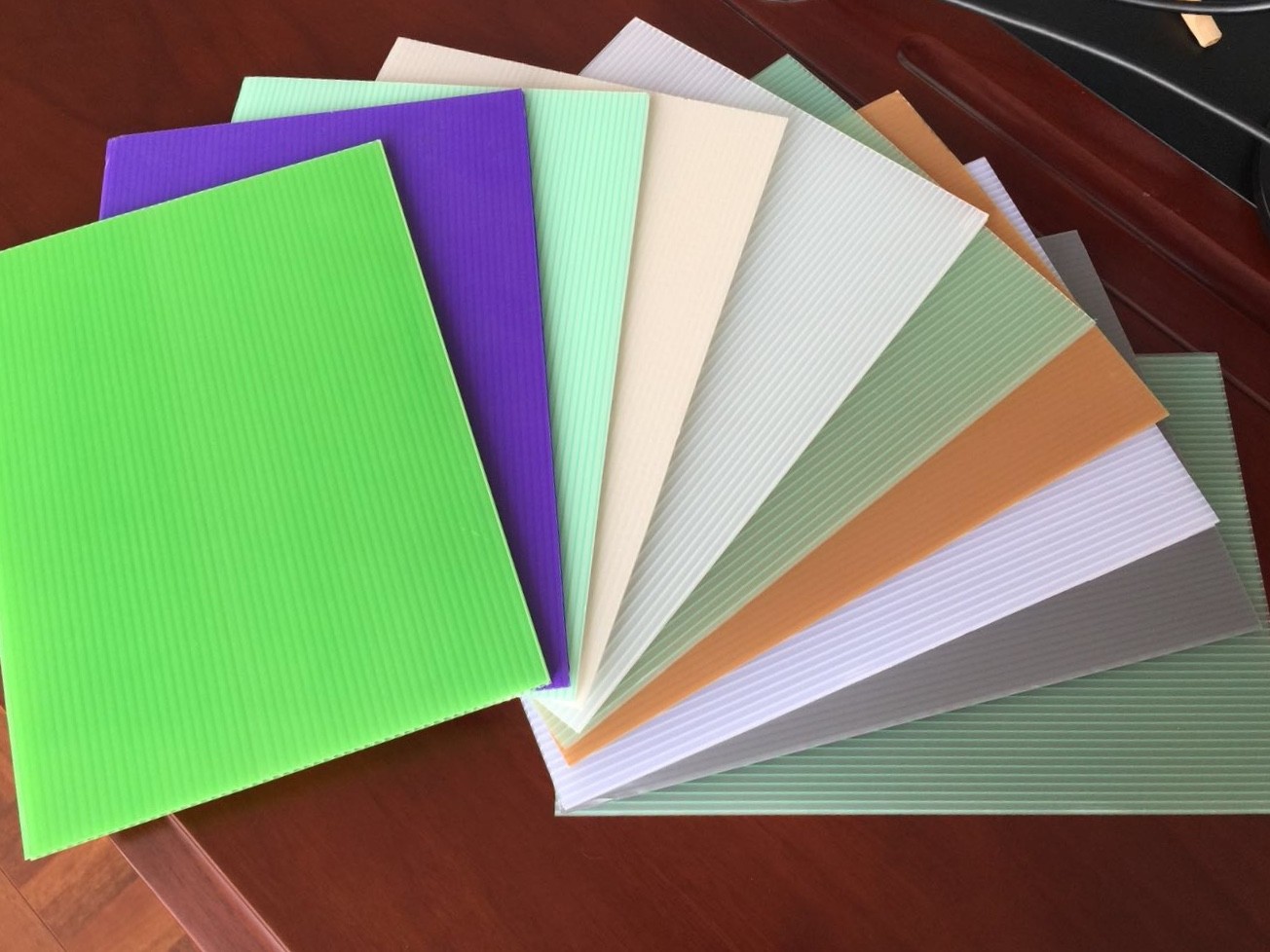

2, PP hollow sheet related products can be flexibly produced, compared to the expensive plastic injection box, PP hollow sheet box cheaper many, customized according to customer size, thickness, toughness, hardness, printing, etc.

3, Traditional cartons will be broken after several times of using, the PP hollow sheet crates life is about 20 times of the carton material, or even longer, it can reduce the using cost greatly.

4, And the PP hollow sheet products are non-toxic, pollution-free, environmental protection, waterproof, moisture-proof, shock absorption and other characteristics, compared with traditional cardboard, wood, easy to use, easy to store, can be reused, long life, but also recycling, Higher social and economic value.

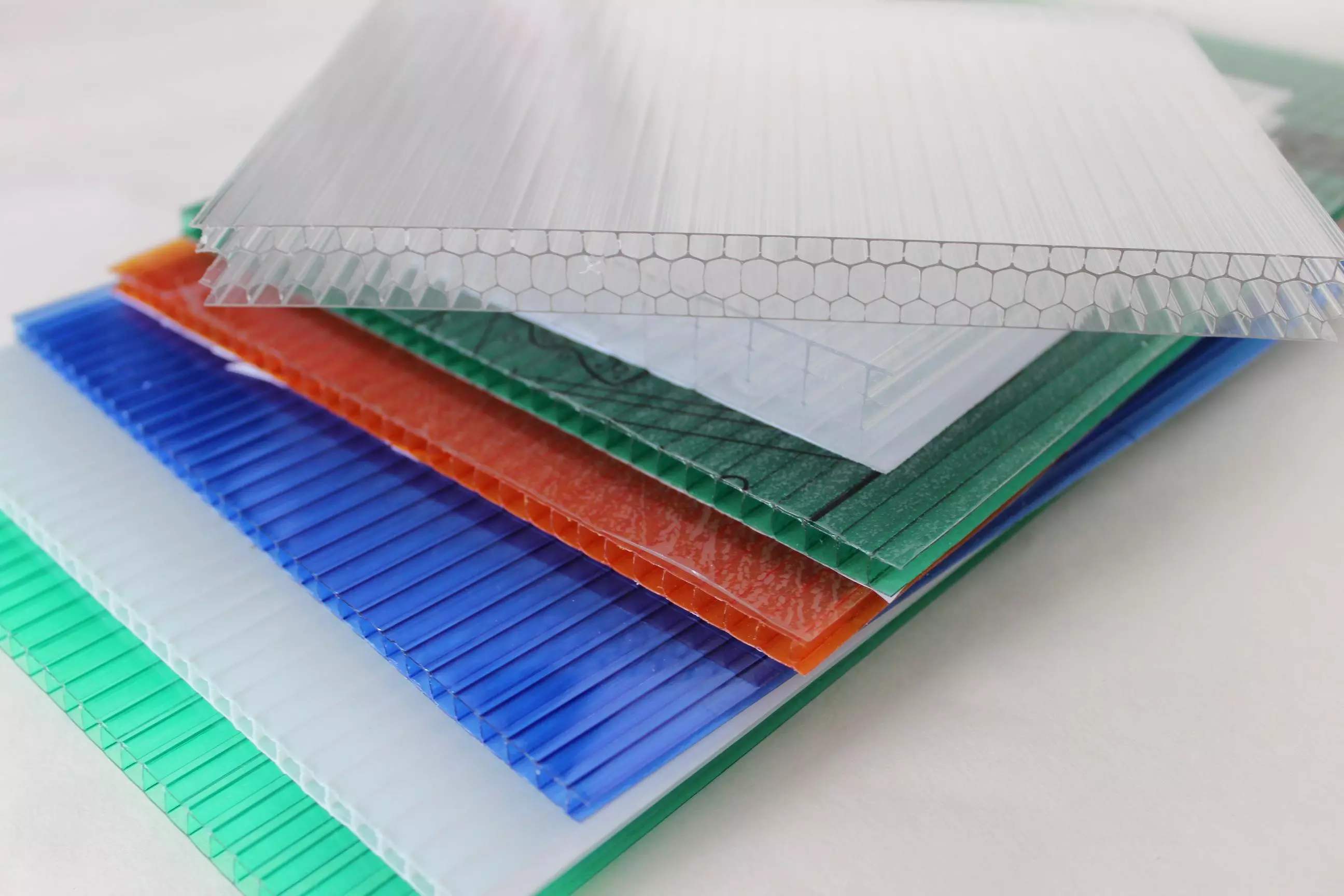

IV, hollow lattice features

1, PP hollow sheet with the same processing properties of cardboard, can be nailed, can be cut, bonded, printable, pressed into a box.

2 ,PP hollow sheet has better physical properties than the carton, carton stability than good, not easy to tear, impact resistance is better than the carton, add colorant, cover the composite layer can be made of colorful products.

3, the grid plate with a waterproof, corrosion-resistant, moisture-resistant, insects are not boring, not long fungi, acid and alkali, harmless, pollution-free and other excellent performance.

4, the PP hollow sheet in use can be processed into a similar carton printing appearance, carton hardness than high, long life, good toughness, high strength, energy conservation. Quality products, light, smooth surface

5, Advantage of PP hollow sheet comparing with canton box:

Parameter | PP hollow sheet | Canton box |

Fire resistance | yes | no |

recyclable | 100% recyclable | 40% recyclable |

Water absorption | no | yes |

Deformation | no | yes |

Corrosion resistance | Good | Bad |

Acid resistance | Good | Bad |

Alkali resistance | good | bad |

Pollution in production | No | Heavy pollution |

Anti-insect | Yes | No |

Anti-molds | Yes | No |

V, Market advantage of PP hollow sheet material

1, lower labor costs. Grate plate can be extruded directly, a molding, greatly reducing labor costs.

2, lattice board product performance is perfect. Plaid with the unparalleled advantages of paper materials, set environmental protection, simple, moisture-proof, anti-scratch and other advantages in one.

3, grating products more prominent environmental performance. Grid components are made of environmentally friendly materials, consumers use completely 100% recovery, recovery process will not produce loss.

4, more cost-effective. Plates and paper materials, the price is high. But the actual operation will be completely different, the grid plate can be repeatedly used many times, light weight, save a lot of cost.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash