Edge Banding Making Machine for Furniture Table Door Board /pvc strip edge banding tape making machine

group namePlastic Sheet Machine

-

Min Order1 piece

brand nametongsan

modelSJ65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeThu, 14 Jan 2021 16:08:49 GMT

Paramtents

product width 600mm

material pvc with caco3

screw 65/132 connical double screw extruder

forming type three roller calender

cooling air

Packging & Delivery

Min Order1 piece

Briefing

Detailed

The main component of PVC sealing strip is polyvinyl chloride, which is made by mixing, calendering, vacuum molding and so on.

Products are widely used in furniture, office, kitchenware, teaching equipment, civil laboratory and so on. The thickness ranges from 0.3 to 3mm, and the width is from 12mm to 80mm.

Products have the following main features: smooth surface, no foaming, no stretching, gloss moderate, surface and back level, uniform thickness, uniform width, reasonable hardness, high elasticity, good quality, strong wear resistance, trimmed side color and surface color close to the edge, no whitening, good gloss, furniture products overall color synergy Tune.

The pvc edge banding machine flow chat

Extruder---hydralic meshwork exchange------mould-----three rollers calender device-----haulf off device---cutting machine---coiler machine--splitting machine----printing machine

|

Machine list

|

Quantity

|

|

material loading device

|

one set

|

|

SJSZ65/132 connical double screw extruder

|

one set

|

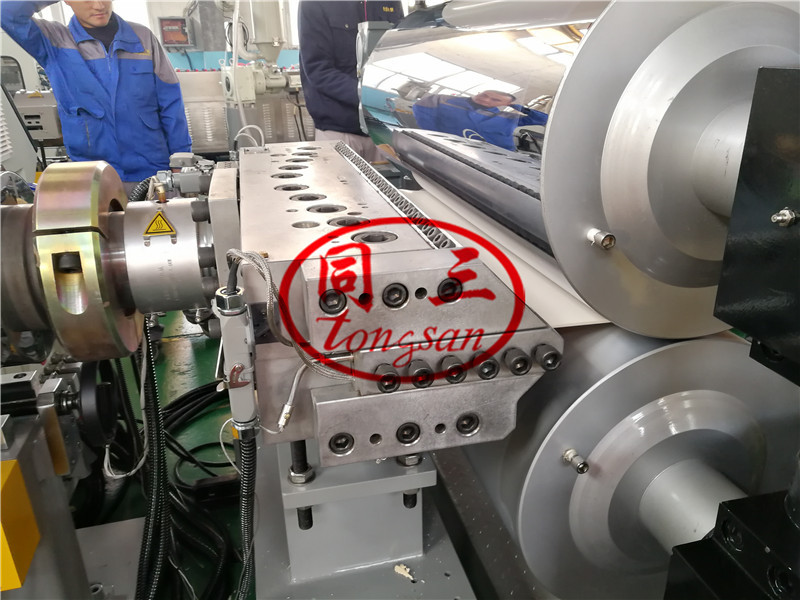

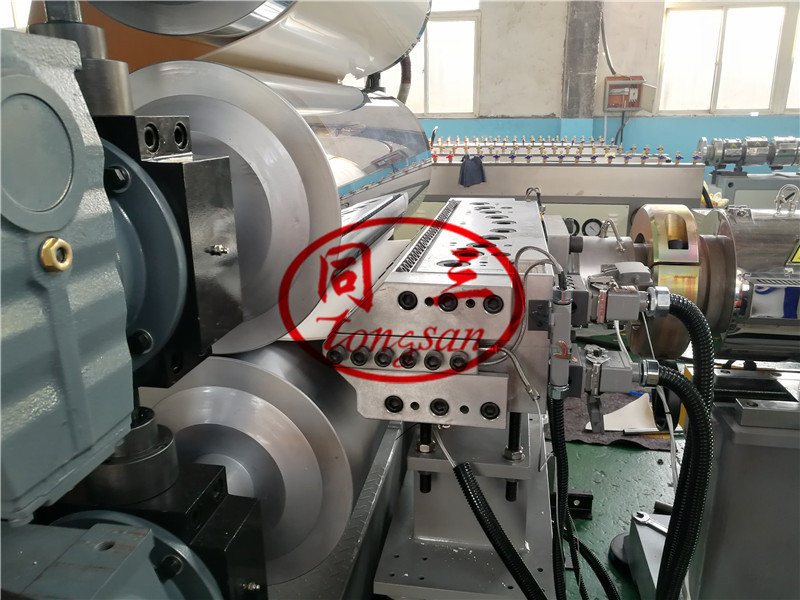

die unit | one set |

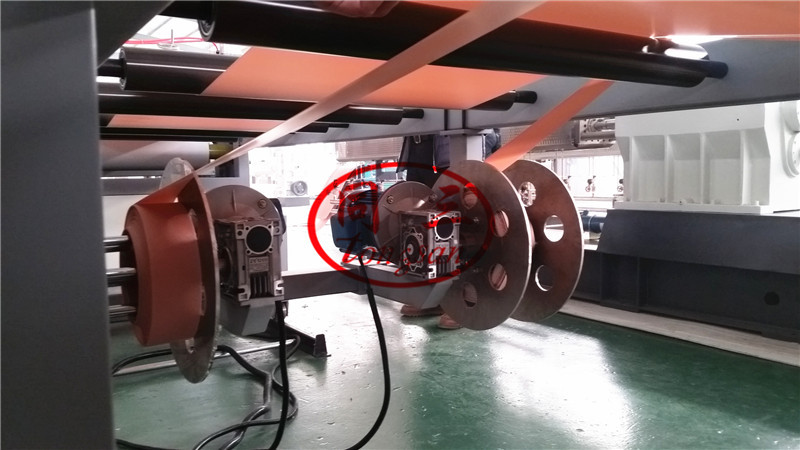

Three-roller calendaring machine | one set |

Cooling bracket | one set |

Hauling off device | one set |

Cutting device | one set |

Stainless steel stacker | one set |

Electricity control system | one set |

Quantity of Knives: two sets

Roller material: rubber

Speed control: Frequency

Qingdao Tongsan Plastic Machinery Co., Ltd. was established in 1997 as a professional Plastic machinery manufacturer, situated on the prosperous Jiaozhou bay, is exclusively specializing in designing and manufacturing a great variety of plastic machinery. With national scientific manpower, our company is engaged in the researching of late-model plastic machinery, the conversion of the international advanced technology and cooperation with the research institutes and universities to provide plastic machinery with high performance and high technology.

The main product of our company is

PP Hollow Sheet Extrusion Machinery,

Plastic single wall corrugated pipe machinery,

Plastic double wall corrugated pipe machinery,

PE water supplying pipe machine,

PVC water supplying pipe machine,

recycled plastic pelletizing machine,

WPC profile machine, WPC board machine, WPC foaming board line.

And our Products have Obtained CE Certificates.

For the future, TONGSAN proposes the development strategy of "making a priority to develop international business, comprehensively promoting domestic business" to face the two markets, employ two kinds of resources, change development mode, and promote transformation and upgrading, and in creating customer satisfaction projects, to maximize shareholders' benefits and pursue the growth of both organization and staff.

All the staff of our company adheres to the principle of "trust is root, client is god, high quality is first, service is best" that we want to do business with the people all over the world on mutual benefit.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram